Abstract

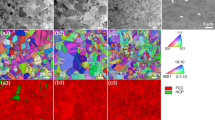

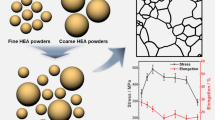

The present work investigates the thermal stability and mechanical properties of a Co–20Cr–15W–10Ni (wt%) alloy with a bimodal grain (BG) structure. The BG structure consisting of fine grains (FGs) and coarse grains (CGs) is thermally stable under high-temperature exposure treatments of 760 °C for 100 h and 870 °C for 100–1000 h. The size of both FGs and CGs remains no significant changes after thermal exposure treatments. The microstructural stability is associated with the slow kinetics of grain growth and the pinning of carbides. The thermal stability enables to maintain the BG structures, leading to the same mechanical properties as the sample without thermal exposure treatment. In particular, the BG alloy samples after thermal exposure treatment exhibit superior mechanical properties of both high strength and high ductility compared to the unimodal grain (UG) structured ones. The BG structure of the alloy samples after thermal exposure is capable of avoiding severe loss of ductility and retaining high strength. More specifically, the ductility of the BG alloy samples after thermal exposure treatments of 870 °C for 500–1000 h is ten times higher (44.6% vs. 3.5% and 52.6% vs. 5.0%) than that of the UG ones. The finding in the present work may give new insights into high-temperature applications of the Co–20Cr–15W–10Ni alloy and other metallic materials with a BG structure.

Graphical abstract

Similar content being viewed by others

References

Bao HS, Gong ZH, Chen ZZ, Yang G. Evolution of precipitates in Ni–Co–Cr–W–Mo superalloys with different tungsten contents. Rare Met. 2020;39(6):716.

Wang J, Xue H, Wang Y. Oxidation behavior of Ni-based superalloy GH738 in static air between 800 and 1000 °C. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01513-2.

Jia YJ, Chen HN, Liang XD. Microstructure and wear resistance of CoCrNbNiW high-entropy alloy coating prepared by laser melting deposition. Rare Met. 2019;38(12):1153.

Khoddamzadeh A, Liu R, Liang M, Yang Q. Wear resistant carbon fiber reinforced Satellite alloy composites. Mater Des. 2014;56:487.

Zhong F, Tao ZL, Sha JB. Improvement of isothermal oxidation resistance of a γ′-strengthened Co–Al–W–Mo–Ta–B alloy at 800 °C via doping Ce. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01436-y.

Zhao C, Zhou J, Mei Q, Ren F. Microstructure and dry sliding wear behavior of ultrafine-grained Co-30 at% Cr alloy at room and elevated temperatures. J Alloys Compd. 2019;770:276.

Kumar VA, Gupta RK, Murty SVSN, Durga A. Hot workability and microstructure control in Co20Cr15W10Ni cobalt-based superalloy. J Alloys Compd. 2016;676:527.

Zhu ZY, Meng L, Chen L. Strain-induced martensitic transformation in biomedical Co–Cr–W–Ni alloys. Rare Met. 2020;39(3):241.

Zhang EL, Fu S, Wang RX, Li HX, Liu Y, Ma ZQ, Liu GK, Zhu CS, Qin GW, Chen DF. Role of Cu element in biomedical metal alloy design. Rare Met. 2019;38(6):476.

Samii Zafarghandi M, Abbasi SM, Momeni A. Effects of Nb on hot tensile deformation behavior of cast Haynes 25 Co–Cr–W–Ni alloy. J Alloys Compd. 2019;774:18.

Ueki K, Ueda K, Narushima T. Microstructure and mechanical properties of heat-treated Co–20Cr–15W–10Ni alloy for biomedical application. Metall Mater Trans A. 2016;47:2773.

Teague J, Cerreta E, Stout M. Tensile properties and microstructure of Haynes 25 alloy after aging at elevated temperatures for extended times. Metall Mater Trans A. 2004;35:2767.

Ueki K, Ueda K, Nakai M, Nakano T, Narushima T. Microstructural changes during plastic deformation and corrosion properties of biomedical Co–20Cr–15W–10Ni alloy heat-treated at 873 K. Metall Mater Trans A. 2018;49:2393.

Ueki K, Yanagihara S, Ueda K, Nakai M, Nakano T, Narushima T. Overcoming the strength-ductility trade-off by the combination of static recrystallization and low-temperature heat-treatment in Co–Cr–W–Ni alloy for stent application. Mater Sci Eng A. 2019;766:138400.

Li CL, Park CH, Choi SW, Lee SW, Hong JK, Yeom JT. High strength and high ductility in the Co–20Cr–15W–10Ni alloy having a bimodal grain structure achieved by static recrystallization. Mater Sci Eng A. 2018;732:70.

Li CL, Oh JM, Yeom JT, Park CH. Bimodal grain-structure formation in a Co–Cr-based superalloy during ultrahigh-homologous-temperature annealing without severe plastic deformation. J Alloys Compd. 2019;783:173.

Li CL, Oh JM, Choi SW, Hong JK, Yeom JT, Mei XM, Mei QS, Yu ZT, Park CH. Study on microstructure and mechanical property of a biomedical Co–20Cr–15W–10Ni alloy during multi-pass thermomechanical processing. Mater Sci Eng A. 2020;785:139388.

Li CL, Choi SW, Oh JM, Hong JK, Yeom JT, Kang JH, Mei QS, Park CH. Bimodal grain structures and tensile properties of a biomedical Co–20Cr–15W–10Ni alloy with different pre-strains. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01566-3.

Sabzi HE, Zarei Hanzaki A, Abedi HR, Soltani R, Mateo A, Roa JJ. The effects of bimodal grain size distributions on the work hardening behavior of a TRansformation-TWinning induced plasticity steel. Mater Sci Eng A. 2016;678:23.

Park HK, Ameyama K, Yoo J, Hwang H, Kim HS. Additional hardening in harmonic structured materials by strain partitioning and back stress. Mater Res Lett. 2018;6(5):261.

Zhang H, Wang H, Wang J, Rong J, Zha M, Wang C, Ma PK, Jiang QC. The synergy effect of fine and coarse grains on enhanced ductility of bimodal-structured Mg alloys. J Alloys Compd. 2019;780:312.

Zheng R, Li G, Zhang Z, Zhang Y, Yue S, Chen X, Ameyama K, Ma C. Manipulating the powder size to achieve enhanced strength and ductility in harmonic structured Al alloy. Mater Res Lett. 2019;7(6):217.

Peng HR, Gong MM, Chen YZ, Liu F. Thermal stability of nanocrystalline materials: thermodynamics and kinetics. Int Mater Rev. 2017;62(6):303.

Shahandeh S, Militzer M. Grain boundary curvature and grain growth kinetics with particle pinning. Philos Mag. 2013;93(24):3231.

Wang N, Wen Y, Chen LQ. Pinning of grain boundary migration by a coherent particle. Philos Mag Lett. 2014;94(12):794.

Zhang X, Misra A. Superior thermal stability of coherent twin boundaries in nanotwinned metals. Scr Mater. 2012;66:860.

Watanabe T. Grain boundary engineering: historical perspective and future prospects. J Mater Sci. 2011;46:4095.

Huang WQ, Yang XG, Li SL. Evaluation of service-induced microstructural damage for directionally solidified turbine blade of aircraft engine. Rare Met. 2019;38(2):157.

Qi HY, Yang JS, Yang XG, Li SL. Low-cycle fatigue behavior of a directionally solidified Ni-based superalloy subjected to gas hot corrosion pre-exposure. Rare Met. 2019;38(3):227.

Keyvani M, Garcin T, Fabrègue D, Militzer M, Yamanaka K, Chiba A. Continuous measurements of recrystallization and grain growth in cobalt super alloys. Metall Mater Trans A. 2017;48:2363.

Favre J, Fabrègue D, Maire E, Chiba A. Grain growth and static recrystallization kinetics in Co–20Cr–15W–10Ni (L-605) cobalt-base superalloy. Philos Mag. 2014;94(18):1992.

Hirano KI, Agarwala RP, Averbach BL, Cohen M. Diffusion in cobalt-nickel alloys. J Appl Phys. 1962;33:3049.

Sargent PM, Malakondaiah G, Ashby MF. A deformation map for cobalt. Scr Metall. 1983;17:625.

Kim SG, Park YB. Grain boundary segregation, solute drag and abnormal grain growth. Acta Mater. 2008;56:3739.

Cherukuri B, Srinivasan R, Tamirisakandala S, Miracle D. The influence of trace boron addition on grain growth kinetics of the beta phase in the beta titanium alloy Ti–15Mo–2.6Nb–3Al–0.2Si. Scr Mater. 2009;60:496.

Qu SG, Wang GH, Yang ZX, Lai FQ, Xiong ZH, Ke H, Li XQ. Microstructure and tribological properties of carburized 95W–3.5Ni–1.0Fe–0.5Co heavy alloy. Rare Met. 2019;38(2):165.

Zhu Z, Chen L. Effect of annealing on microstructure and mechanical properties of biomedical hot-rolled Co–Cr–W–Ni alloy. Mater Res Express. 2019;6(12):126511.

Pineau A, Benzerga AA, Pardoen T. Failure of metals I: brittle and ductile fracture. Acta Mater. 2016;107:424.

Acknowledgements

This work was financially supported by the Fundamental Research Program of Korea Institute of Materials Science, Republic of Korea (No. PNK7140) and the National Key Research and Development Project, China (No. 2020YFC1107200).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, CL., Oh, J.M., Choi, SW. et al. Thermal stability of bimodal grain structure in a cobalt-based superalloy subjected to high-temperature exposure. Rare Met. 40, 877–884 (2021). https://doi.org/10.1007/s12598-020-01627-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01627-7