Abstract

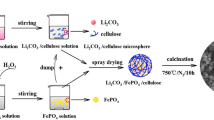

CeO2 is one of the main catalysts for solid oxide fuel cell (SOFC). It is critical to find a green and cost-effective fabrication method for CeO2 at scale. In this study, the CeO2 microspheres were prepared by one-step ultrasonic spray pyrolysis of cerium chloride solution at 700 °C. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) study demonstrate that the prepared CeO2 microspheres exhibit a particle size of 0.01–1.08 μm with a mean particle size of 0.23 μm, and more than 94% of the particles have a diameter less than 0.5 μm. But the presence of residual Cl in the fabricated CeO2 microspheres blocks the active sites and leads to the significant degradation of SOFC performance. The formation mechanism and distribution of residual Cl in the fabricated CeO2 microspheres were systemically studied. The water washing method was shown to effectively reduce the residual Cl in the CeO2 microspheres. Overall, this work provides a clean manufacturing process for the preparation of SOFC electrode/electrolyte materials.

Similar content being viewed by others

References

Leng J, Wang ZX, Wang JX, Wu HH, Yan GC, Li XH, Guo HJ, Liu Y, Zhang QB, Guo ZP. Advances in nanostructures fabricated via spray pyrolysis and their applications in energy storage and conversion. Chem Soc Rev. 2019;48(11):3015.

Zhao YF, Guo JC. Development of flexible Li-ion batteries for flexible electronics. InfoMat. 2020;2(5):866.

Krishnaswamy K, Pitchaipillai M, Karunamoorthy S, Karikalan S, Ayyasami K. Photocatalytic degradation of environmental perilous gentian violet dye using leucaena-mediated zinc oxide nanoparticle and its anticancer activity. Rare Met. 2019;38(4):277.

Hegazy AR, Salameh B, Alsmadi A. Optical transitions and photoluminescence of fluorine-doped zinc tin oxide thin films prepared by ultrasonic spray pyrolysis. Ceram Int. 2019;45(15):19473.

Park SY, Kim Y, Kim T, Eom TH, Kim SY, Jang HW. Chemoresistive materials for electronic nose: progress, perspectives, and challenges. InfoMat. 2019;1(3):289.

Patil PS. Versatility of chemical spray pyrolysis technique. Mater Chem Phys. 1999;59(3):185.

Napari M, Huq TN, Hoye RLZ, Driscoll JLM. Nickel oxide thin films grown by chemical deposition techniques: potential and challenges in next generation rigid and flexible device applications. InfoMat. 2020;2(1):1.

Li X, Qi SH, Zhang WC, Feng YZ, Ma JM. Recent progress on FeS2 as anodes for metal-ion batteries. Rare Met. 2020. https://doi.org/10.1007/s12598-020-01492-4.

Jang H, Taniguchi I. Influence of impregnated carbon on preparation and electrochemical properties of Li2FeP2O7 composite synthesized by spray pyrolysis. J Alloys Compd. 2017;709(30):557.

Mao S, Bao R, Fang D, Yi JH. Facile synthesis of Ag/AgX (X = Cl, Br) with enhanced visible-light-induced photocatalytic activity by ultrasonic spray pyrolysis method. Adv Powder Technol. 2018;29(11):2670.

Jung DS, Hwang TH, Lee JH, Koo HY, Shakoor RA, Kahraman R, Jo YN, Park MS, Choi JW. Hierarchical porous carbon by ultrasonic spray pyrolysis yields stable cycling in lithium sulfur battery. Nano Lett. 2014;14(8):4418.

Okuyama K, Lenggoro IW. Preparation of nanoparticles via spray route. Chem Eng Sci. 2003;58(3):537.

Deepa KG, Jampana N. Development of an automated ultrasonic spray pyrolysis system and the growth of Cu2ZnSnS4 thin films. J Anal Appl Pyrol. 2016;117:141.

Lv L, Wang YL, Cheng PF, Zhang B, Dang F, Xu LP. Ultrasonic spray pyrolysis synthesis of three dimensional ZnFe2O4 based macroporous spheres for excellent sensitive acetone gas sensor. Sens Actuators Chem. 2019;297:126755.

Yin SH, Chen K, Srinivasakannan C, Guo S, Li SW, Peng JH. Enhancing recovery of ammonia from rare earth wastewater by air stripping combination of microwave heating and high gravity technology. Chem Eng J. 2018;337:515.

Gao GH, Lai FG, Xu HX, Zhang Q, Guo H, Xiao YF. Enrichment of rare earth from low concentration rare earth sulfate solution by calcium oxide precipitation. Chin J Rare Met. 2019;43(4):409.

Huang XW, Long ZQ, Wang LS, Feng ZY. Technology development for rare earth cleaner hydrometallurgy in China. Rare Met. 2015;34(4):215.

Kuang ST, Zhang ZF, Li YL, Wei HQ, Liao WP. Extraction and separation of heavy rare earths from chloride medium by α-aminophosphonic acid HEHAPP. J Rare Earths. 2018;36(3):304.

Ju JW, Huan DM, Zhang YX, Xia CR, Cui GL. Ionic conductivity of infiltrated Ln (Ln = Gd, Sm, Y)-doped ceria. Rare Met. 2018;37(9):734.

Wu WY, Bian X. Rare earth metallurgy technology. Beijing: The Science Publishing Company; 2012. 216.

Li CQ, Li RX, Cong F, Song XZ, Gu MJ. Solvothermal synthesis of titania/ceria. Rare Met. 2011;30(1):544.

Escudero MJ, Serrano JL. Individual impact of several impurities on the performance of direct internal reforming biogas solid oxide fuel cell using W-Ni-CeO2 as anode. Int J Hydrog Energy. 2019;44(36):20616.

Pelleg J. Diffusion in ceramics. Solid mechanics and its applications. Basel: Springer; 2016. 52.

Thommes M, Cychosz KA. Physical adsorption characterization of nanoporous materials: progress and challenges. Adsorption. 2014;20(2–3):233.

Shi CW, Liu JJ, Wu WY, Bian X, Chen P, Yang Z, Lu CT. Toward understanding of the effect of nucleation temperature on porous structure of micro-mesoporous composite molecular sieves and related crystallization mechanism. Catalysts. 2019;9(9):777.

Li YJ, Xu P, Chen GL, Mou JR, Xue SF, Li K, Zheng FH, Dong QF, Hu JH, Yang CH, Liu ML. Enhancing Li-S redox kinetics by fabrication of a three dimensional Co/CoP@nitrogen-doped carbon electrocatalyst. Chem Eng J. 2020;380:122595.

Thommes M, Kaneko K, Neimark AV, Olivier JP, Rodriguez-Reinoso F, Rouquerol J, Sing KS. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). Pure Appl Chem. 2015;87(9–10):1051.

Chiang YC, Chiang PC, Huang CP. Effects of pore structure and temperature on VOC adsorption on activated carbon. Carbon. 2001;39(4):523.

Messing GL, Zhang SC, Jayanthi GV. Ceramic powder synthesis by spray pyrolysis. J Am Ceram Soc. 1993;76(11):2707.

Blake PG, Carley AF, Di CV, Roberts MW. Chemisorptive replacement of surface oxygen by hydrogen halides (HCl and HBr) at Pb(110) surfaces. Photoelectron spectroscopic and kinetic evidence for a metastable chloride overlayer. J Chem Soc Faraday Trans Phys Chem Condens Phases. 1986;82(3):723.

Acknowledgements

This study was financially supported by the National Key R&D Program of China (No. 2018YFB1502600) the National Natural Science Foundation of China (Nos. 51922042 and 51872098), China Postdoctoral Science Foundation (No. 2019M652888) and the Sino-Singapore International Joint Research Institute (SSIJRI), China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, SF., Li, YJ., Zheng, FH. et al. Characterization of CeO2 microspheres fabricated by an ultrasonic spray pyrolysis method. Rare Met. 40, 31–39 (2021). https://doi.org/10.1007/s12598-020-01594-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01594-z