Abstract

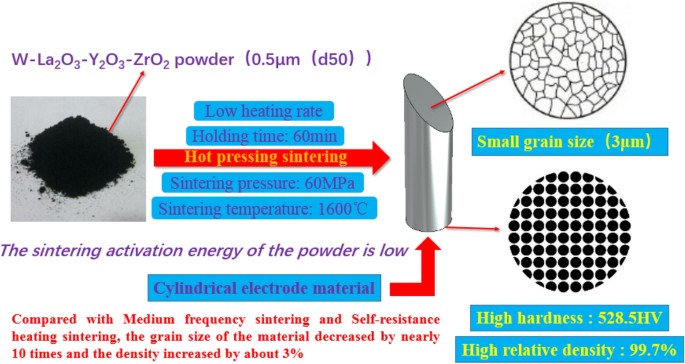

The W–La2O3–Y2O3–ZrO2 materials were prepared by vacuum hot pressing sintering process. The microstructure was characterized by scanning electron microscopy (SEM). The effects of sintering temperature, sintering pressure, holding time and heating rate on relative density, hardness and microstructure were studied. The sintering activation energy of the powder was calculated. Based on the result, the best sintering parameters by vacuum hot pressing sintering are as follows: sintering temperature of 1600 °C, sintering pressure of 60 MPa and holding time of 60 min. The heating rate is 10 °C·min−1 from room temperature to 1000 °C and 4 °C·min−1 from 1000 to 1600 °C. Using this process, the grain size is about 3 μm in diameter with relative density at 99.7%, and the hardness is HV 528.5. The sintering characteristic index (n) of the specimen is 4, and the sintering mechanism mainly depends on the diffusion from the surface to the intragranular in the volume diffusion. The sintering activation energy of W–La2O3–Y2O3–ZrO2 material is 286.2 kJ·mol−1, which indicates that the powder has higher activity in sintering process.

Graphic abstract

Similar content being viewed by others

References

Wang MY, Jia MX, Xiao YW, Sun CY, Li YF, Jin JW. The present situation and countermeasures of substainable development of tungsten resources in China. Nonferrous Met Eng. 2014;4(2):76.

Chen J. Analysis of the present situation of rare earth resources in the world and countermeasures for sustainable development of rare earth resources in China. Res Agric Modernization. 2012;33(1):000074.

Feng F, Lian Y, Wang J, Chen Z, Liu X, Tang J, Huang B. Irradiation effects of H/He neutral beam on different forged tungsten materials. Tungsten. 2019;1(2):169.

Yin H, Wang J, Guo W, Cheng L, Yuan Y, Lu G. Recent studies of tungsten-based plasma-facing materials in the linear plasma device STEP. Tungsten. 2019;1(2):132.

Hu W, Ma Q, Ma Z, Huang Y, Wang Z, Liu Y. Ultra-fine W–Y2O3 composite powders prepared by an improved chemical co-precipitation method and its interface structure after spark plasma sintering. Tungsten. 2019;1(3):220.

Schade P. 100 years of doped tungsten wire. Int J Refract Met Hard Mater. 2010;28(6):648.

Kim Y, Lee KH, Kim EP, Cheong DI, Hong SH. Fabrication of high temperature oxides dispersion strengthened tungsten composites by spark plasma sintering process. Int J Refract Met Hard Mater. 2009;27(5):842.

Rieth M, Dafferner B. Limitations of W and W–1%La2O3 for use as structural materials. J Nucl Mater. 2005;342(1):20.

Veleva L, Oksiuta Z, Vogtb U, Baluc N. Sintering and characterization of W–Y and W–Y2O3 materials. Fusion Eng Des. 2009;84(7):1920.

Cui YT, Zhang SG, Wang M, Zhang X, Ren XJ. Development of multi-element composite rare earth tungsten electrode for high performance plasma spraying gun. Therm Spray Technol. 2014;6(2):24.

OuYang CX, Zhu SG, Ma J, Qu HX, Li Q. The effect of the two stage hot pressing sintering process on the microstructure and mechanical properties of WC-MgO composites. China Nonferrous Met J. 2012;22(12):3395.

Ma YZ, Huang BY, Liu WS. Research status and development trend of tungsten based alloy materials. Powder Metall Ind. 2005;15(5):46.

Xiong HP, Zhang LM, Li JG, Shen Q, Yuan RZ. The preparation of W-Mo-Ti-Ti-Al line density gradient material. Chin Nonferrous Met Sinter Process. 2000;10(4):491.

Zhang L, Chen S, Shan C, Huang FJ, Cheng X, Ma Y. Hot pressing densification of WC-MoxC binderless carbide. Trans Nonferrous Met Soc China. 2012;22(8):2027.

Zhang S, Fan JL, Cheng HC, Tian JM, Cheng CG. The sintering behavior and microstructure evolution of W–TiC alloy. J Cent South Univ Nat Sci Ed. 2012;43(8):2938.

Ruan JM, Huang PY. Principles of Powder Metallurgy. Beijing: China Machine Press; 2012. 246.

Wu EX, Wu AH. Effect of sintering temperature on properties of high tungsten heavy alloys. Rare Met Cem Carbides. 2004;32(1):16.

Lin JZ, Jin ZJ, Shi SJ, Zhong XH, Jiang GN. Hot pressing sintering of tungsten alloys for diamond polishing. Chin J Nonferrous Met. 2015;25(3):682.

Guo SJ. Theory of Powder Sintering. Beijing: Metallurgical Industry Press; 1998. 338.

Ma YP, Luo H, Song RJ, Zeng KL, Liu KY. Effect of sintering process parameters on mechanical properties of metal injection moulded In713C alloy. Mater Res Appl. 2018;12(2):102.

Liu XJ, Yuan TC, Li RD, Zeng FH, Liu GH. Effect of heating rate on densification of iron powder by spark plasma sintering. Sci Eng Powder Metall Mater. 2017;22(2):177.

Huang PY. Principles of Powder Metallurgy. Beijing: Metallurgical Industry Press; 1997. 272.

Matsui K, Tanaka K, Yamakawa T, Uehara M, Enomoto N, Hojo J. Sintering kinetics at isothermal shrinkage: II, effect of Y2O3 concentration on the initial sintering stage of fine zirconia powder. J Am Ceram Soc. 2007;90(1):44.

Luis A, Pérez M, José MC, Concepción R. Kinetics of the initial stage of sintering from shrinkage data: simultaneous determination of activation energy and kinetic model from a single nonisothermal experiment. J Am Ceram Soc. 2002;85(4):763.

Sato E, Carry C. Effect of powder granulometry and pre-treatment on sintering behavior of submicron-grained α-Al2O3. J Eur Ceram Soc. 1995;15(1):9.

Fang TT, Shiue JT, Shiau FS. On the evaluation of the activation energy of sintering. Mater Chem Phys. 2003;80(1):108.

Hirai S, Shimakage K, Saitou Y, Nishimura T, Uemura Y, Mitomo M, Brewer L. Synthesis and sintering of cerium(III) sulfide powders. J Am Ceram Soc. 1998;81(1):145.

Guillaume BG, Christian G. Apparent activation energy for the densification of a commercially available granulated zirconia powder. J Am Ceram Soc. 2007;90(4):1246.

Lee WJ, Fang TT. Effect of the strontium: barium ratio and atmosphere on the sintering behavior of strontium barium niobate. J Am Ceram Soc. 1998;81(2):300.

Tian Y. Vacuum Sintering of Tungsten with Two-Scale Grain Distribution and Its Properties. Xi’an: Chang’an University, 2017. 52.

Acknowledgements

This study was financially supported by the National Natural Science Foundation for Innovative Research Group Projects (No. 51621003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, BG., Yang, JC., Gao, ZK. et al. Hot pressing sintering process and sintering mechanism of W–La2O3–Y2O3–ZrO2. Rare Met. 40, 1949–1956 (2021). https://doi.org/10.1007/s12598-020-01530-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01530-1