Abstract

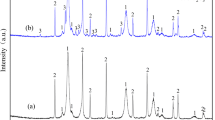

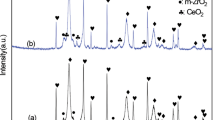

Al2O3–ZrO2–TiO2 coatings were successfully prepared by plasma spraying Al2O3–ZrO2 composite powders with and without TiO2 addition. The effects of TiO2 on the phase composition, microstructure and properties of the Al2O3–ZrO2 coating were studied. The results show that the Al2O3–ZrO2–TiO2 composite powder was composed of t-ZrO2, α-Al2O3, m-ZrO2 and rutile, while the Al2O3–ZrO2–TiO2 composite coating consisted of t-ZrO2, α-Al2O3 and γ-Al2O3. The diffraction peaks of TiO2 could not be detected in the Al2O3–ZrO2–TiO2 coating even up to 10 wt% TiO2 addition. The reason may be that TiO2 was dissolved in the amorphous phase or formed solid solution with γ-Al2O3 phase in the coating during cooling. Compared with the Al2O3–ZrO2 coating, the as-prepared Al2O3–ZrO2–TiO2 coating had denser microstructure, less microcracks and more amorphous phases. The density of the Al2O3–ZrO2–TiO2 coating increased with the increase of TiO2 content. The Al2O3–ZrO2–10wt%TiO2 coating had the most uniform and dense microstructure, possessed higher toughness, adhesive strength and wear resistance compared with the Al2O3–ZrO2 coating, which was due to its lower porosity and more uniform microstructure.

Graphic abstract

Similar content being viewed by others

References

Wang Y, Yang Y, Tian W, Li CG. Thermal sprayed WC-Co coatings and their mechanical properties. Rare Met. 2007;26(S1):280.

Song YS, Lee IG, Lee DY, Kim DJ, Kim S, Lee K. High temperature properties of plasma sprayed coatings of YSZ/NiCrAlY on In-conel substrate. Mater Sci Eng, A. 2002;332(1–2):129.

Shan X, Wei LQ, Liu P, Zhang XM, Tang WX, Qian P, He Y, Ye SF. Influence of CoO glass-ceramic coating on the antioxidation behavior and thermal shock resistance of 200 stainless steel at elevated temperture. Ceram Int. 2014;40(8):12327.

Wang Y, Darut G, Poirier T, Stella J, Liao HL, Planche MP. Ultrasonic cavitation erosion of as-sprayed and laser-remelted yttria stabilized zirconia coatings. J Eur Ceram Soc. 2017;37(11):3623.

Cai LF, Zhang YZ, Shi LK. Microstructure and formation mechanism of titanium matrix composites coating on Ti-6Al-4 V by laser cladding. Rare Met. 2007;26(4):342.

Li H, Sun YZ, Zhang J. Effect of ZrO2 particle on the performance of microarc-oxidation coatings on Ti6Al4V. Appl Surf Sci. 2015;342:183.

Gao HD, Wang ZH, Shao J. Manufacture and characteristics of Al2O3 composite coating on steel substrate by SHS process. Rare Met. 2019;38(7):704.

Song JB, Choi E, Oh SG, So J, Lee SS, Kim JT, Yun JY. Improved reliability of breakdown voltage measurement of yttrium oxide coatings by plasma spray. Ceram Int. 2019;45(17):22169.

Ambardekar V, Bandyopadhyay PP, Majumder SB. Hydrogen sensing performance of atmospheric plasma sprayed tin dioxide coating. Int J Hydrogen Energ. 2019;44(26):14092.

Wang F, Luo GN, Huang JJ, Liu Y. Properties improvement of atmospheric plasma sprayed tungsten coating by annealing. Surf Coa Technol. 2019;358:276.

Luo LM, Zhang YX, Zan X, Liu JQ, Zhu XY, Wu YC. Status and development of self-propagating high-temperature synthesis of high melting point powders. Chin J Rare Met. 2018;42(11):1210.

Sathish Sharma G, Sugavaneswaran M, Vijayalakshmi U, Prakash R. Influence of γ-alumina coating on surface properties of direct metal laser sintered 316L stainless steel. Ceram Int. 2019;45(10):13456.

Kishida S, Ju DY, He H, Li Y. Coating of γ-Al2O3 on the stainless steel substrate by electrophoretic deposition method. J Environ Soc Sci. 2009;21(1):S112.

Si TZ, Liu N, Zhang QA, You XQ. Thermal shock fatigue behavior of TiC/Al2O3 composite ceramics. Rare Met. 2008;27(3):308.

Zhang JX, He JN, Dong YC, Li XZ, Yan DR. Microstructure and properties of Al2O3–13%TiO2 coatings sprayed using nanostructured powders. Rare Met. 2007;26(4):391.

Limarga AM, Widjaja S, Yip TH. Mechanical properties and oxidation resistance of plasma-sprayed multilayered Al2O3/ZrO2 thermal barrier coatings. Surf Coa Technol. 2005;197(1):93.

Ito A, You Y, Ichikawa T, Tsuda K, Goto T. Preparation of Al2O3–ZrO2 nanocomposite films by laser chemical vapour deposition. J Eur Ceram Soc. 2014;34(1):155.

Chen YD, Yang Y, Chu ZH, Chen XG, Wang L, Liu Z, Dong YC, Yan DR, Zhang JX, Kang ZL. Microstructure and properties of Al2O3–ZrO2 composite coatings prepared by air plasma spraying. Appl Surf Sci. 2018;431:193.

Jia SK, Zou Y, Xu JY, Wang J, Yu L. Effect of TiO2 content on properties of Al2O3 thermal barrier coatings by plasma spraying. Trans Nonferrous Met Soc China. 2015;25(1):175.

Girisha KG, Sreenivas Rao KV, Durga Prasad C. Slurry erosion resistance of martenistic stainless steel with plasma sprayed Al2O3–40%TiO2 coatings. Mater Today Proc. 2018;5(2):7388.

Klyatskina E, Espinosa-Fernandez L, Darut G, Segovia F, Salvador MD, Montavon G, Agorges H. Sliding wear behavior of Al2O3–TiO2 coatings fabricated by the suspension plasma spraying technique. Tribol Lett. 2015;59(1):2.

Fervel V, Normand B, Coddet C. Tribological behavior of plasma sprayed Al2O3-based cermet coatings. Wear. 1999;230(1):70.

Younes R, Bradai MA, Sadeddine A, Mouadji Y, Bilek A, Benabbas A. Effect of TiO2 and ZrO2 reinforcements on properties of Al2O3 coatings fabricated by thermal flame spraying. Trans Nonferrous Met Soc China. 2016;26(5):1345.

Toma FL, Stahr CC, Berger LM, Saaro S, Herrmann M, Deska D, Michael G. Corrosion resistance of APS-and HVOF-sprayed coatings in the Al2O3–TiO2 system. J Therm Spray Technol. 2010;19(1–2):137.

Palanivelu R, Ruban Kunmar A. Scratch and wear behaviour of plasma sprayed nano ceramics blillayer Al2O3–13 wt%TiO2/hydroxyapatite coated on medical grade titanium substrates in SBF environment. Appl Surf Sci. 2014;315:372.

Kusoglua IM, Celika E, Cetinel H, Ozdemir I, Demirkurt O, Onel K. Wear behavior of flame-sprayed Al2O3–TiO2 coatings on planin carbon steel substrates. Surf Coat Techol. 2005;200(1–4):1173.

Yang Y, Wang Y, Tian W, Yan DR, Zhang JX, Wang L. Influence of composite powders’ microstructure on the microstructure and properties of Al2O3–TiO2 coatings fabricated by plasma spraying. Mater Des. 2015;65:814.

Yang Y, Cui YH, Miao LL, Wang Y, Tian W, Ma YD, Zhang X, Zhang C, Chen XG, Wang L, Dong YC, Dai XR. Effects of treatment process and nano-additives on the microstructure and properties of Al2O3–TiO2 nanocomposite powders used for plasma spraying. Powder Technol. 2018;338:304.

Singh VP, Sil A, Jayaganthan R. Tribological behavior of plasma sprayed Cr2O3–3%TiO2 coatings. Wear. 2011;272(1):149.

Dinesh Babu P, Prasannakumar B, Marimuthun P, Mishra RK, Ram Prabhu T. Microstructure, wear and mechanical properties of plasma sprayed TiO2 coating on Al–SiC metal matrix composite. Arch Civ Mech Eng. 2019;19(3):756.

Ramachndran K, Selvarjan V, Anathapadmanbhan PV, Sreekumar KP. Microstructure, adhesion, microhardness, abrasive wear resistance and electrical resistivity of the plasma sprayed alumina and alumina–titania coatings. Thin Solid Films. 1998;315(1):144.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos.51672067, 51541208 and 51102074), the Natural Science Foundation of Hebei Province (Nos.E2018202034 and E2015202070), the Talent Training Project in Hebei Province (No.A2016002026) and the Top Talents in Universities in Hebei Province (No.SLRC2017027).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, PY., Ma, YD., Sun, WW. et al. Microstructure and properties of Al2O3–ZrO2–TiO2 composite coatings prepared by plasma spraying. Rare Met. 40, 1825–1834 (2021). https://doi.org/10.1007/s12598-020-01505-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01505-2