Abstract

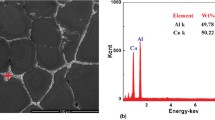

Al–Cu–Li alloy is a huge potential alloy for aerospace industry due to its low density and excellent comprehensive performances. In this study, the microstructures and mechanical properties of a novel cast Al–Cu–Li alloy during the heat treatment were investigated. Results showed that most of the secondary phases along grain boundaries in as-cast state were dissolved into the Al matrix after homogenization and solution treatment, while the Cu-rich phases were slightly segregated once again on grain boundaries after aging. A relatively good combination of strength and ductility (average ultimate tensile strength of 430 MPa and elongation of 8.9%) was obtained after natural aging. Transmission electron microscopy (TEM) results revealed that there was a complicated precipitate distribution in this cast alloy after natural aging. Compared with the similar alloys which introduced dislocations before aging, the density of T1 (Al2CuLi) phases was decreased but the size was increased. The low volume fraction of δ′ phase, medium density of needle-shaped precipitates and relativity narrow precipitates-free zone with varying widths near grain boundary are the reasons accounting for the improvement of performances.

Graphic abstract

Similar content being viewed by others

References

Rioja RJ, Liu J. The evolution of Al–Li base products for aerospace and space applications. Metall Mater Trans Phys Metall Mater Sci. 2012;43A(9):3325.

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des. 2014;56:862.

Deschamps A, Decreus B, De Geuser F, Dorin T, Weyland M. The influence of precipitation on plastic deformation of Al–Cu–Li alloys. Acta Mater. 2013;61(11):4010.

Ma YL, Lin XH, Liu DY, Lu DD, Li JF. Aging precipitates, static and dynamic performance of two Al–Li alloy sheets. Chin J Rare Met. 2019;43(7):673.

Yang SL, Shen J, Zhang YA, Li ZH, Li XW, Huang SH, Xiong BQ. Processing maps and microstructural evolution of Al–Cu–Li alloy during hot deformation. Rare Met. 2019;38(12):1136.

Deng Y, Bai J, Wu X, Huang G, Cao L, Huang L. Investigation on formation mechanism of T-1 precipitate in an Al–Cu–Li alloy. J Alloys Compd. 2017;723:661.

Yoshimura R, Konno TJ, Abe E, Hiraga K. Transmission electron microscopy study of the evolution of precipitates in aged Al–Li–Cu alloys: the theta’ and T-1 phases. Acta Mater. 2003;51(14):4251.

Kang SJ, Kim TH, Yang CW, Lee JI, Park ES, Noh TW, Kim M. Atomic structure and growth mechanism of T-1 precipitate in Al–Cu–Li–Mg–Ag alloy. Scr Mater. 2015;109:68.

Gao Z, Liu JZ, Chen JH, Duan SY, Liu ZR, Ming WQ, Wu CL. Formation mechanism of precipitate T-1 in AlCuLi alloys. J Alloys Compd. 2015;624:22.

Gumbmann E, De Geuser F, Sigli C, Deschamps A. Influence of Mg, Ag and Zn minor solute additions on the precipitation kinetics and strengthening of an Al–Cu–Li alloy. Acta Mater. 2017;133:172.

Ringer SP, Muddle BC, Polmear IJ. Effects of cold work on precipitation in Al–Cu–Mg–(Ag) and Al–Cu–Li–(Mg–Ag) alloys. Metall Mater Trans A. 1995;26(7):1659.

Chen A, Peng Y, Zhang L, Wu G, Li Y. Microstructural evolution and mechanical properties of cast Al–3Li–1.5Cu–0.2Zr alloy during heat treatment. Mater Charact. 2016;114:234.

Zhang X, Zhang L, Wu G, Liu W, Shi C, Tao J, Sun J. Microstructural evolution and mechanical properties of cast Al–2Li–2Cu–0.5Mg–0.2Zr alloy during heat treatment. Mater Charact. 2017;132:312.

Nikitin SL, Osintsev OE, Betsofen SY. Effect of heat treatment conditions on the structure and mechanical properties of a cast Al–Li–Cu aluminum alloy. Russ Metall. 2010;2010(11):1041.

Decreus B, Deschamps A, De Geuser F, Donnadieu P, Sigli C, Weyland M. The influence of Cu/Li ratio on precipitation in Al–Cu–Li-x alloys. Acta Mater. 2013;61(6):2207.

Li HY, Tang Y, Zeng ZD, Zheng ZQ, Zheng F. Effect of ageing time on strength and microstructures of an Al–Cu–Li–Zn–Mg–Mn–Zr alloy. Mater Sci Eng Struct Mater Prop Microstruct Process. 2008;498(1–2):314.

Dorin T, Deschamps A, De Geuser F, Weyland M. Quantitative description of the T-1 morphology and strengthening mechanisms in an age-hardenable Al–Li–Cu alloy. In: Proceedings of the 13th International Conference on Aluminum Alloys (Icaa13). Pittsburgh; 2012:1155.

Shukla AK, Baeslack WA. Study of microstructural evolution in friction-stir welded thin-sheet Al–Cu–Li alloy using transmission-electron microscopy. Scr Mater. 2007;56(6):513.

Csontos AA, Starke EA. The effect of inhomogeneous plastic deformation on the ductility and fracture behavior of age hardenable aluminum alloys. Int J Plast. 2005;21(6):1097.

Pletcher BA, Wang KG, Glicksman ME. Experimental, computational and theoretical studies of delta’ phase coarsening in Al–Li alloys. Acta Mater. 2012;60(16):5803.

Zhang SF, Zeng WD, Yang WH, Shi CL, Wang HJ. Ageing response of a Al–Cu–Li 2198 alloy. Mater Des. 2014;63:368.

Ma PP, Liu CH, Wu CL, Liu LM, Chen JH. Mechanical properties enhanced by deformation-modified precipitation of θ′-phase approximants in an Al–Cu alloy. Mater Sci Eng A. 2016;676:138.

Bourgeois L, Dwyer C, Weyland M, Nie JF, Muddle BC. Structure and energetics of the coherent interface between the theta’ precipitate phase and aluminium in Al–Cu. Acta Mater. 2011;59(18):7043.

Barr SC, Rylands LM, Jones H, Rainforth WM. Formation and characteristics of coarsening resistant cubic sigma phase in Al–4.2Cu–1.6Mg–0.2Si. Met Sci J. 2014;13(8):655.

Suresh S, Vasudevan AK, Tosten M, Howell PR. Microscopic and macroscopic aspects of fracture in lithium-containing aluminum alloys. Acta Metall. 1987;35(1):25.

Pasang T, Symonds N, Moutsos S, Wanhill RJH, Lynch SP. Low-energy intergranular fracture in Al–Li alloys. Eng Fail Anal. 2012;22:166.

Gao C, Zhu ZX, Han J, Li HJ. Correlation of microstructure and mechanical properties in friction stir welded 2198-T8 Al–Li alloy. Mater Sci Eng Struct Mater Prop Microstruct Process. 2015;639:489.

Schneider JA, Nunes AC, Chen PS, Steele G. TEM study of the FSW nugget in AA2195-T81. J Mater Sci. 2005;40(16):4341.

Chen AT, Wu GH, Zhang L, Zhang XL, Shi CC, Li YL. Microstructural characteristics and mechanical properties of cast Al–3Li–xCu–0.2Zr alloy. Mater Sci Eng Struct Mater Prop Microstruct Process. 2016;677:29.

Sanders TH, Starke EA. The effect of slip distribution on the monotonic and cyclic ductility of Al–Li binary alloys. Acta Metall. 1982;30(5):927.

De PS, Mishra RS, Baumann JA. Characterization of high cycle fatigue behavior of a new generation aluminum lithium alloy. Acta Mater. 2011;59(15):5946.

Kumar KS, Brown SA, Pickens JR. Effect of a prior stretch on the aging response of an Al–Cu–Li–Ag–Mg–Zr alloy. Scr Metall Mater. 1990;24(7):1245.

Gayle FW, Heubaum FH, Pickens JR. Structure and properties during aging of an ultra-high strength Al–Cu–Li–Ag–Mg alloy. Scr Metall Mater. 1990;24(1):79.

Costa Teixeira J, Cram DG, Bourgeois L, Bastow TJ, Hill AJ, Hutchinson CR. On the strengthening response of aluminum alloys containing shear-resistant plate-shaped precipitates. Acta Mater. 2008;56(20):6109.

Acknowledgements

This study was financially supported by the Key Research and Development Project of Shandong Province (No. 2018CXGC0403).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Duan, SW., Matsuda, K., Wang, T. et al. Microstructures and mechanical properties of a cast Al–Cu–Li alloy during heat treatment procedure. Rare Met. 40, 1897–1906 (2021). https://doi.org/10.1007/s12598-020-01481-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01481-7