Abstract

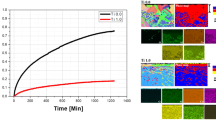

Isothermal oxidation resistance, oxide scale evolution and failure mechanism of Ce-doped Co–Al–W–Mo–Ta–B alloy (0.01 at%, 0.05 at%, 0.10 at% and 0.20 at% Ce) exposed at 800 °C were compared. The 0.01Ce and 0.05Ce alloys were consisted of γ/γ′ coherent microstructure, while the κ-Co3W compound precipitated at the grain boundary of the 0.10Ce and 0.20Ce alloys in addition to the γ/γ′ microstructure. The oxidation kinetics curves of the Ce-doped alloys exhibited a parabolic time dependence on the weight gain. With an increasing nominal Ce content, the weight gain of the Co–Al–W–Mo–Ta–B alloys monotonically decreased. An oxide scale composed of a dense and uniform outer Co3O4 + CoO layer, a middle CoAl2O4 and CoWO4 compound layer and an inner Al2O3 layer. The excellent oxidation resistance of 0.2Ce alloy was mainly attributed to a shorter incubation stage for the formation of the continuous and protective Al2O3 layer and the thickest Al2O3 layer during entire oxidation process.

Similar content being viewed by others

References

Sullivan CP. Cobalt Base Superalloys. Cobalt monograph series Brussels: Centre d’Information du Cobalt. 1970. 173.

Gabb TP, Dreshfied RL, Sims CT, Stoloff NS. Superalloys II. Edited by Hagel WC. New York: Wiley. 1987. 264.

Sato J, Omori T, Oikawa K. Cobalt-base high-temperature alloys. Science. 2006;312(5770):90.

Pollock TM, Argon AS. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall. 1992;40(1):1.

Kolb M, Freund LP, Fischer F, Povstugar I, Makineni SK, Gault B, Raabe D, Müller J, Spiecker E, Neumeier S, Göken M. On the grain boundary strengthening effect of boron in γ/γ′ cobalt-base superalloys. Acta Mater. 2018;145(2):247.

Suzuki A, DeNolf GC, Pollock TM. Flow stress anomalies in γ/γ′ two-phase Co–Al–W-base alloys. Scr Mater. 2007;56(5):385.

Suzuki A, Pollock TM. High-temperature strength and deformation of γ/γ′ two-phase Co–Al–W-base alloys. Acta Mater. 2008;56(5):1288.

Kobayashi S, Tsukamoto Y, Takasugi T, Chinen H, Omori T, Ishida K, Zaefferer S. Determination of phase equilibria in the Co-rich Co–Al–W ternary system with a diffusion-couple technique. Intermetallics. 2009;17(12):1085.

Chen M, Wang CY. First-principles investigation of the site preference and alloying effect of Mo, Ta and platinum group metals in γ′-Co3(Al, W). Scr Mater. 2009;60(8):659.

Titus MS, Mottura A, Viswanathan GB, Suzuki A, Mills MJ, Pollock TM. High resolution energy dispersive spectroscopy mapping of planar defects in L12-containing Co-base superalloys. Acta Mater. 2015;89(5):423.

Shinagawa K, Omori T, Oikawa K, Kainuma R, Ishida K. Ductility enhancement by boron addition in Co–Al–W high-temperature alloys. Scr Mater. 2009;61(6):612.

Makineni SK, Nithin B, Chattopadhyay K. Synthesis of a new tungsten-free γ-γ′ cobalt-based superalloy by tuning alloying additions. Acta Mater. 2015;85(2):85.

Shi L, Yu JJ, Cui CY, Sun XF. Effect of Ta additions on microstructure and mechanical properties of a single-crystal Co–Al–W-base alloy. Mater Lett. 2015;149(6):58.

Feng G, Li H, Li SS, Sha JB. Effect of Mo additions on microstructure and tensile behavior of a Co–Al–W–Ta–B alloy at room temperature. Scr Mater. 2012;67(5):499.

Bauer A, Neumeier A, Pyczak F, Göken M. Microstructure and creep strength of different γ/γ′-strengthened Co-base superalloy variants. Scr Mater. 2010;63(12):1197.

Bauer A, Neumeier S, Pyczak F, Singer RF, Göken M. Creep properties of different γ′-strengthened Co-base superalloys. Mater Sci Eng A. 2012;550(7):333.

Ooshima M, Tanaka K, Okamoto NL, Kishida K, Inui H. Effects of quaternary alloying elements on the γ′ solvus temperature of Co–Al–W based alloys with fcc/L12 two-phase microstructures. J Alloys Compd. 2010;508(1):71.

Yan HY, Vorontsov VA, Dye D. Alloying effects in polycrystalline γ′ strengthened Co–Al–W base alloys. Intermetallics. 2014;48(11):44.

Klein L, Bauer A, Neumeier S, Göken M, Virtanen S. High temperature oxidation of γ/γ′-strengthened Co-base superalloys. Corros Sci. 2011;53(5):2027.

Klein L, Shen Y, Killian MS, Virtanen S. Effect of B and Cr on the high temperature oxidation behaviour of novel γ/γ′-strengthened Co-base superalloys. Corros Sci. 2011;53(9):2713.

Neumeier S, Freund LP, Göken M. Novel wrought γ/γ′ cobalt base superalloys with high strength and improved oxidation resistance. Scr Mater. 2015;108(12):104.

Yan HY, Vorontsov VA, Dye D. Effect of alloying on the oxidation behaviour of Co–Al–W superalloys. Corros Sci. 2014;83(6):382.

Klein L, Killian MS, Virtanen S. The effect of nickel and silicon addition on some oxidation properties of novel Co-based high temperature alloys. Corros Sci. 2013;69(6):43.

Klein L, Bartenwerffer B, Killian MS, Schmuki P, Virtanen S. The effect of grain boundaries on high temperature oxidation of new γ′-strengthened Co–Al–W–B superalloys. Corros Sci. 2014;79(8):29.

Zhong F, Fan F, Li SS, Sha JB. High-temperature oxidation behaviour of novel Co–Al–W–Ta–B–(Mo, Hf, Nb) alloys with a coherent γ/γ′–dominant microstructure. Prog Nat Sci Mater Int. 2016;26(1):600.

Stewart CA, Suzuki A, Pollock TM, Levi CG. Rapid assessment of oxidation behavior in Co-based γ/γ′ alloys. Oxid Met. 2018;90(2):485.

Zhong F, Yu YX, Li SS, Sha JB. In-situ SEM and TEM tensile observations of novel Co–Al–W–Mo–Ta–B-Ce aalloys with a coherent γ-CoSS/γ′-Co3(Al, W) microstructure at room temperature. Mater Sci Eng A. 2017;696(6):96.

Zhong F, Li SS, Sha JB. Tensile behaviour of Co–Al–W–Ta–B–Mo alloys with a coherent γ/γ′ microstructure at room and high temperatures. Mater Sci Eng A. 2015;637(6):175.

Zhong F. Effect of Ce Addition on Microstructure, Mechanical Properties, Oxidation and Corrosion Behaviours of Co–Al–W Based Alloys. Beijing: Beihang University. 2017. 153.

Lee DB, Santella ML. High temperature oxidation of Ni3Al alloy containing Cr, Zr, Mo, and B. Mater Sci Eng A. 2004;374(6):217.

Wang GX, Dahms M. TiAl-based alloys prepared by elemental powder metallurgy. Powder Metall Int. 1992;24(9):219.

Zhang SM, Shi XR, Sha JB. Oxidation behaviours of Nb–22Ti–15Si–2Al–2Hf–2V–(2, 14)Cr alloys with Al and Y modified silicide coatings prepared by pack cementation. Prog Nat Sci Mater Int. 2015;25(5):486.

Wen SH, Sha JB. Isothermal and cyclic oxidation behaviours of MoSi2 with additions of B at 1250 °C prepared by spark plasma sintering. Mater Charact. 2018;139(5):134.

Li TF. Oxidation and Corrosion of Metals at High Temperature. Beijing: Chemistry Industrial Press of China. 2003. 52.

Birks N, Meier GH, Pettit FS. Introduction to High Temperature Oxidation of Metals. 2nd ed. Cambridge: Cambridge University Press. 2006. 134.

Samant MS, Kerkar AS, Bharadwaj SR, Dharwadkar SR. Thermodynamic investigation of the vaporization of molybdenum trioxide. J Alloys Compd. 1992;187(2):373.

Li DQ, Zhou LX, Zhang J, Wang JC, Gu J, Si JJ. Enhanced alumina film adhesion of Hf/Y-doped iron–aluminum alloys during high-temperature oxidation: a new observation. Rare Met. 2019;38(9):877.

Peng H, Guo HB, He J, Gong SK. Microscale lamellar NiCoCrAlY coating with improved oxidation resistance. Surf Coat Technol. 2012;207(21):110.

Liang XB, Sheng XF, Li XG, Ma ML, Yuan JW, Jiang QT. Research on thermal shock resistance of micro-arc oxidation ceramic coating on VW75 Mg alloy modified by nano-Al2O3. Chin J Rare Met. 2019;42(7):679.

Wang W, Zhou CG. Characterization of microstructure and oxidation resistance of Y and Ge modified silicide coating on Nb–Si based alloy. Corros Sci. 2016;110(9):114.

Tian YS, Chen CZ, Chen LX, Huo QH. Effect of RE oxides on the microstructure of the coatings fabricated on titanium alloys by laser alloying technique. Scr Mater. 2006;54(5):847.

Acknowledgements

This study was financially supported by the National Key Research and Development Program of China (No. 2017YFB0702902) and the National Natural Science Foundation of China (No. 51471014).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, F., Tao, ZL. & Sha, JB. Improvement of isothermal oxidation resistance of a γ′-strengthened Co–Al–W–Mo–Ta–B alloy at 800 °C via doping Ce. Rare Met. 40, 2065–2075 (2021). https://doi.org/10.1007/s12598-020-01436-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01436-y