Abstract

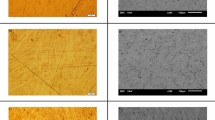

At present, Nb3Sn superconductors are becoming more popular in high magnetic fields. The growth law of Nb3Sn phase in a planar CuSn/Nb diffusion couple has been studied, whereas the formation mechanism of Nb3Sn phase in a cylindrical CuSn/Nb diffusion couple is still controversial. The purpose of this work is to investigate the growth exponent of Nb3Sn phase at the initial stage of annealing by use of scanning electron microscopy (SEM) through which the thickness of Nb3Sn layer can be obtained. In this study, bronze-processed Nb3Sn multifilamentary wires with different annealing time were investigated. The Nb3Sn phase was formed during isothermal annealing at 670 °C by solid-state diffusion, which was accomplished by the movement of Sn atoms from the CuSn/Nb3Sn interface to Nb3Sn/Nb interface. However, the formation mechanism of Nb3Sn phase at the initial stage of annealing is still not well understood. Microstructural evolution of Nb3Sn phase during isothermal annealing was studied by SEM. The mean thickness of the Nb3Sn layer (\(\Delta x_{{{\text{Nb}}_{ 3} {\text{Sn}}}}\)) is expressed as a power function of the annealing time (t) by the equation \(\Delta x_{{{\text{Nb}}_{ 3} {\text{Sn}}}}^{2} = k(t/t_{0} )^{n}\), where t0 is the unit time, k is the reaction rate constant and n is the growth exponent. The growth exponent has the average value of 0.82, which means that the formation of the Nb3Sn phase is both governed by the interface reaction and the grain boundary diffusion.

Similar content being viewed by others

References

Osamura K, Ochiai S, Kondo S, Namatame M, Nosaki M. Influence of third elements on growth of Nb3Sn compounds and on global pinning force. J Mater Sci. 1986;21(5):1509.

Sweedler AR, Schweitzer DG, Webb GW. Atomic ordering and superconductivity in high-Tc A15 compounds. Phys Rev Lett. 1974;33(3):168.

Stewart GR, Newkirk LR, Valencia FA. Impurity stabilized A15 Nb3Nb—a new superconductor. Phys Rev B. 1980;21(11):5055.

Devantay H, Jorda JL, Decroux M, Muller J, Fluekiger R. The physical and structural properties of superconducting A15-type Nb–Sn alloys. J Mater Sci. 1981;16(8):2145.

Godeke A. A review of the properties of Nb3Sn and their variation with A15 composition, morphology and strain state. Supercond Sci Technol. 2006;19(8):68.

Sandim MJR, Tytko D, Kostka A, Choi P, Awaji S, Watanabe K, Raabe D. Grain boundary segregation in a bronze-route Nb3Sn superconducting wire studied by atom probe tomography. Supercond Sci Technol. 2013;26(5):7.

Wang HY, Ding FZ, Gu HW, Zhang HL, Dong ZB. Microstructure and superconducting properties of BaTiO3/Y2O3-doped YBCO films under different firing temperature. Rare Met. 2017;36(1):37.

Oguro H, Awaji S, Watanabe K, Sugimoto M, Tsubouchi H. New fabrication process of Cu–Nb composite for internal reinforcement of Nb3Sn wires. J Supercond. 2013;26(5):2099.

Foner S, Schwartz BB. Superconductor Materials Science: Metallurgy Fabrication and Applications. New York: Plenum Press; 1981. 201.

Sharma RG. Review on the fabrication techniques of A-15 super- conductors. Cryogenics. 1987;27(7):361.

Paul A, Laurila T, Vuorinen V. Superconductor—Microstructure, Diffusion and Growth Mechanism of Nb3Sn Superconductor by Bronze Technique. São Paulo: Condensed Matter Physics; 2010. 48.

Philibert J. Atom Movements—Diffusion and Mass Transport in Solids. Paris: Physics; 1991. 96.

Kumar AK, Paul A. Interdiffusion and growth of the superconductor Nb3Sn in Nb/Cu(Sn) diffusion couples. J Electron Mater. 2009;38(5):700.

Laurila T, Vuorinen V, Kumar AK, Paul A. Diffusion and growth mechanism of Nb3Sn superconductor grown by bronze technique. Appl Phys Lett. 2010;96(23):231910.1.

Suenaga M, Jansen W. Chemical compositions at and near the grain boundaries in bronze-processed superconducting Nb3Sn. Appl Phys Lett. 1983;43(8):791.

Yoon KE, Noebe RD, Hellman OC, Seidman DN. Dependence of interfacial excess on the threshold value of the isoconcentration surface. Surf Interface Anal. 2004;36(5–6):594.

Tachikawa K, Itoh K, Kamata K, Moriai H, Tada N. Improved multifilamentary Nb3Sn conductors produced by the titanium-bronze process. J Nucl Mater. 1985;133:830.

Zhou WL, Wang ZL. Scanning Microscopy for Nanotechnology. New York: Springer; 2006. 41.

Goldstein J, Newbury D, Joy D, Lyman C. Scanning Electron Microscopy and X-Ray Microanalysis. New York: Springer; 2003. 453.

Engler O, Randle V. Introduction to Texture Analysis. London: CRC Press; 2010. 30.

Volkert CA, Minor AM. Focused ion beam microscopy and micromachining. MRS Bull. 2007;32(5):389.

Blaugher RD, Hein RE, Cox JE. Atomic ordering and superconductivity in A-15 compounds. J Low Temp Phys. 1969;1(6):539.

Upadhyay P, Samanta SB, Narlikar AV. Growth kinetics studies of multifilamentary Nb3Sn formed by the bronze method. Mater Res Bull. 1981;16(6):741.

Farrell HH, Gilmer GH, Suenaga M. Grain boundary diffusion and growth of intermetallic layers: Nb3Sn. J Appl Phys. 1974;45(9):4025.

Farrell HH, Gilmer GH. Diffusion mechanisms for the growth of Nb3Sn intermetallic layers. Thin Solid Films. 1975;25(1):253.

Fluekiger R, Uglietti D, Senatore C, Buta F. Microstructure, composition and critical current density of superconducting Nb3Sn wires. Cryogenics. 2008;48(7):293.

Cantoni M, Abaecherli V, Uglietti D, Seeber B, Fluekiger R. Analytical TEM of Nb3Sn multifilament superconductor wires. Microsc Microanal. 2008;14(S2):1146.

Gottstein G. Physical Foundations of Materials Science. Berlin: Springer; 2004. 267.

Muranishi Y, Kajihara M. Growth behavior of Nb3Sn layer during reactive diffusion between Cu–8.3Sn alloy and Nb. Mater Sci Eng A. 2005;404(1):33.

Hayase T, Kajihara M. Kinetics of reactive diffusion between Cu–8.1Sn–0.3Ti alloy and Nb. Mater Sci Eng A. 2006;433(1–2):83.

Acknowledgements

This study was financially supported by the Nuclear Material Technology Innovation Center for National Defense Technology and Industry (No. ICNM-2019-YZ-03).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, SR., Hu, B., Ren, HJ. et al. Initial stages of Nb3Sn phase formation in Nb-bronze matrix composite wires investigated by means of electron microscopy. Rare Met. 40, 708–713 (2021). https://doi.org/10.1007/s12598-020-01398-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01398-1