Abstract

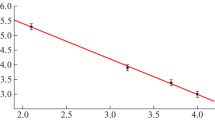

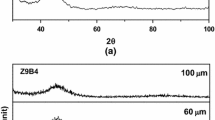

The phase transformation and magnetic hysteresis properties of melt-spun Fe41Pd41B8Si6P4 ribbons subjected to the annealing at temperatures of 500–550 °C were studied after holding for 0.1–60.0 h by transmission electron microscopy (TEM), X-ray diffraction (XRD) and thermomagnetic analysis. The additions of P, B and Si to the FePd alloy allowed us to achieve the coercivity of 124 kA·m−1, which is 2.6 times higher than that of the melt-spun ribbons of the binary equiatomic FePd alloy. The high-coercivity Fe41Pd41B8Si6P4 alloy is nanocrystalline and is composed of the ordered L10-phase grains approximately 40 nm in size and inclusions of the Fe2(P, B) and Pd2(Si, B) phases. The coercivity kinetics is controlled by the phase transformation which can be divided into three stages: transformation from the bcc structure to nanosized regions of the fcc and Fe2P phases; transformation from the fcc to L10 nanosized regions with somewhat different degrees of tetragonality and their ordering; and extensive growth of the weight fraction of L10 phase from the fcc nanosized regions. P and B atoms occupy interstitial sites in the iron plane of L10 lattice, thus decreasing its Curie temperature (TC).

Similar content being viewed by others

References

Sakuma N, Ohshima T, Shoji T, Suzuki Y, Sato R, Wachi A, Kato A, Kawai Y, Manabe A, Teranishi T. Exchange coupling interaction in L10-FePd/α-Fe nanocomposite magnets with large maximum energy products. ACS Nano. 2011;5(4):2806.

Hsiao CH, Yao YD, Lo SC, Chang HW, Ouyang C. Domain wall pinning on strain relaxation defects (stacking faults) in nanoscale FePd (001)/MgO thin films. Appl Phys Lett. 2015;107(14):142407.

Liu T, Ma L, Zhao SQ, Ma DD, Li L, Cheng G, Rao GH. Crystal structure and magnetic properties of FexPd1−x thin films annealed at 550 °C. J Mater Sci Mater Electron. 2017;28(4):3616.

Saha S, Kulovits A, Soffa WA, Barnard JA. Synthesis of Fe–Pd and Fe–PdTa magnetic nanocomposites by severe plastic deformation. J Appl Phys. 2005;97(10):10F301.

Cantando ED, Ludtka GM, Mackiewicz-Ludtka G, Soffa WA. Electron microscopy study of hypostoichiometric Fe–Pd nanocomposites resulting from combined reactions thermomechanical processing. Solid State Phenom. 2011;172–174:356.

Wiezorek JMK. Cold-working and annealing of L10-ordering iron-palladium base intermetallics. Mater Sci Forum. 2007;539–543:1487.

Vlasova NI, Kleinerman NM, Serikov VV, Popov AG. Mössbauer study of fine structure features of equiatomic FePd alloy after severe plastic deformation and ordering annealing. J Alloys Compd. 2014;583:191.

Zhang B, Soffa WA. Structure and properties of rapidly-solidified iron–platinum and iron–palladium alloys. IEEE Trans Magn. 1990;26(5):1388.

Inoue A, Takeuchi A. Recent progress in bulk glassy alloys. Mater Trans. 2002;43(8):1892.

Kündig AA, Abe N, Ohnuma M, Ohkubo T, Mamiya H, Hono K. Rapidly solidified (FePt)70P30 alloy with high coercivity. Appl Phys Lett J Appl Phys. 2004;85(5):789.

Zhang W, Kazahari A, Yubuta K, Makino A, Inoue A. The structure and magnetic properties of melt-spun Fe55Pt25B18M2 (M = C, P, Si) alloys. J Phys Conf Ser. 2009;144:012072.

Zhang W, Kazahari A, Yubuta K, Makino A, Wang Y, Umetsu R, Li Y. Effect of P addition on the structure and magnetic properties of melt-spun Fe–Pt–B alloy. J Alloys Compd. 2014;586:S294.

Sato K, Sharma P, Zhang Y, Takenaka K, Makino A. Crystallization induced ordering of hard magnetic L10 phase in melt-spun FeNi-based ribbons. AIP Adv. 2016;6(5):055218.

Kovács A, Sato K, Hirotsu Y. Strong perpendicular magnetic anisotropy of Fe–Pd nanocrystalline particles enhanced by Co addition. J Appl Phys. 2007;101(3):033910.

Naganuma H, Sato K, Hirotsu Y. Perpendicular magnetic anisotropy of epitaxially grown L10-FePdCu nanoparticles with preferential c-axis orientation. J Appl Phys. 2006;100(7):074914.

Tokuoka Y, Seto Y, Kato T, Iwata S. Effect of Ag addition to L10 FePt and L10 FePd films grown by molecular beam epitaxy. J Appl Phys. 2014;115(17):17B716.

Popov AG, Vlasova NI, Gaviko VS, Kleinerman NM, Serikov VV, Golovnia OA. Magnetic properties and structure of Fe50Pd50−xNix alloys (x = 4 and 8) in the as-deformed and annealed state. J Alloys Compd. 2017;701:892.

Chen YT, Ou JW. Magnetic, optical, and electrical properties of Fe40Pd40B20 thin-films. J Alloys Compd. 2014;605:179.

Chen Y, Tseng C. Adhesive properties of FePdB thin films. J Nanosci Nanotechnol. 2017;17(4):2457.

Jiang JZ, Saksl K, Nishiyama N, Inoue A. Crystallization in Pd40Ni40P20 glass. J Appl Phys. 2002;92(7):3651.

Hsiao AC, Lewis LH, Kang K, Moodenbaugh AR. Magnetism and metastability of melt-spun Pd40(Fe, Ni)40P20 metallic glass. J Appl Phys. 2006;99(8):08F117.

Sharon TE, Tsuei CC. Magnetism in amorphous Fe–Pd–P alloys. Phys Rev B. 1972;5(3):1047.

Maitrepierre PL. Structure of amorphous Ni–Pd–P and Fe–Pd–P alloys. J Appl Phys. 1969;40(12):4826.

Rodriguez-Carvajal J. Recent developments of the program FULLPROF. Comm Powder Diffr Newsl. 2001;26:12.

Giles PM, Longenbach MH, Marder AR. High-pressure α\(\rightleftarrows\)ε martensitic transformation in iron. J Appl Phys. 1971;42(11):4290.

Sanati M, Zunger A. Evolution of L12 ordered domains in fcc Cu3Au alloy. J Phys Condens Matter. 2007;19(8):086201.

Artigas M, Bacmann M, Fruchart D, Wolfers P. Structure characterization of FePdP: stabilization of a new polytype of the MM’X series. J Alloys Compd. 1991;176:105.

Vlasova NI, Popov AG, Shchegoleva NN. Effect of the structural state of the FePd equiatomic alloy on the temperature dependence of the initial magnetic susceptibility and the Curie temperature. Phys Met Metallogr. 2009;107(4):359.

Caron L, Hudl M, Höglin V, Dung NH, Gomez CP, Sahlberg M, Brück E, Andersson Y, Nordblad P. Magnetocrystalline anisotropy and the magnetocaloric effect in Fe2P. Phys Rev B. 2013;88(9):094440.

Chandra R, Bjarman S, Ericsson T, Häggström L, Wilkinson C, Wäppling R, Andersson Y, Rundqvist SA. Mössbauer and X-ray study of Fe2P1−xBx compounds (x < 0.15). J Solid State Chem. 1980;34(3):389.

Jernberg P, Yousif AA, Häggström L, Andersson Y. A Mössbauer study of Fe2P1−xSix (x ≤ 0.35). J Solid State Chem. 1984;53(3):313.

Vlasova NI, Gaviko VS, Popov AG, Shchegoleva NN, Stashkova LA, Gunderov DV, Sauvage X. Phase transformations in ferromagnetic nanostructured FePd alloy under severe plastic deformation and annealing. Solid State Phenom. 2010;168–169:392.

Chbihi A, Sauvage X, Genevois C, Blavette D, Gunderov D, Popov AG. Optimization of the magnetic properties of FePd alloys by severe plastic deformation. Adve Eng Mater. 2010;12(8):708.

Vlasova NI, Kandaurova GS, Shchegoleva NN. Effect of the polytwinned microstructure parameters on magnetic domain structure and hysteresis properties of the CoPt-type alloys. J Magn Magn Mater. 2000;222(1–2):138.

Acknowledgements

This work was financially supported by the Indian–Russian Collaborative Project (Nos. 17-52-45097 and INT/RUS/RFBR/P-267) and the State Assignment of Ministry of Science and Education of Russia (No. AAAA-A18-118020290129-5). The X-ray diffraction investigation and the magnetic measurements have been performed in the Center of Collaborative Access of IMP UB RAS. The authors gratefully appreciate the help of Dr. Yaron Kauffman and Eng. Michael Kalina from the MIKA center at the Technion—Israel Institute of Technology—for help in samples preparation and conducting the TEM measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Golovnia, O.A., Vlasova, N.I., Popov, A.G. et al. Development of high-coercivity state in melt-spun Fe41Pd41B8Si6P4 ribbons. Rare Met. 39, 76–83 (2020). https://doi.org/10.1007/s12598-019-01256-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01256-9