Abstract

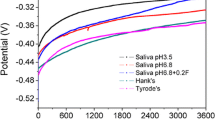

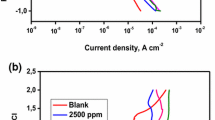

Ti–3Cu alloy has shown low melting point and strong antibacterial properties against S. aureus and E. coli and thus has potential application as dental materials and orthopedic application. In this paper, the corrosion properties of Ti–3Cu alloy in five kinds of simulated solutions were investigated in comparison with cp-Ti (commercially pure titanium) by electrochemical technology and immersion experiment. Electrochemical results have demonstrated that Ti–3Cu alloy exhibited much nobler corrosion potential, lower corrosion current density and high corrosion resistance than cp-Ti in all solutions, especially in saliva-pH6.8 + 0.2F and saliva-pH3.5, indicating that Ti–3Cu alloy has much better anticorrosion properties than cp-Ti. Immersion results have shown that Ti ion and Cu ion were released from Ti–3Cu, especially in saliva-pH6.8 + 0.2F and saliva-pH3.5 solutions. Both electrochemical data and immersion results have indicated that high corrosion rate and high metal ion release rate were detected in F ion-containing solution and low-pH solution, displaying that F− and low pH had much strong aggressive attack to cp-Ti and Ti–3Cu alloy. The corroded surface morphology was observed by scanning electron microscopy (SEM), and the roughness was tested in the end. The good corrosion resistance of antibacterial Ti–3Cu alloy suggests its great potential as a long-term biomedical application.

Similar content being viewed by others

References

Niinomi M. Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci Technol Adv Mater. 2003;4(5):445.

Rack HJ, Qazi JI. Titanium alloys for biomedical applications. Mater Sci Eng C-Biomim Supramol Syst. 2006;26(8):1269.

Wilches LV, Uribe JA, Toro A. Wear of materials used for artificial joints in total hip replacements. Wear. 2008;265(1–2):143.

Elias CN, Lima JHC, Valiev R, Meyers MA. Biomedical applications of titanium and its alloys. JOM. 2008;60(3):46.

Tamilselvi S, Raman V, Rajendran N. Corrosion behaviour of Ti–6Al–7Nb and Ti–6Al–4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim Acta. 2006;52(3):839.

Vasilescu C, Drob P, Vasilescu E, Demetrescu I, Ionita D, Prodana M, Drob SI. Characterisation and corrosion resistance of the electrodeposited hydroxyapatite and bovine serum albumin/hydroxyapatite films on Ti–6Al–4V–1Zr alloy surface. Corrosion Sci. 2011;53(3):992.

Al-Mayouf AM, Al-Swayih AA, Al-Mobarak NA, Al-Jabab AS. Corrosion behavior of a new titanium alloy for dental implant applications in fluoride media. Mater Chem Phys. 2004;86(2–3):320.

Pulikkottil VJ, Chidambaram S, Bejoy P, Femin P, Paul P, Rishad M. Corrosion resistance of stainless steel, nickel-titanium, titanium molybdenum alloy, and ion-implanted titanium molybdenum alloy archwires in acidic fluoride-containing artificial saliva: an in vitro study. J Pharm Bioallied Sci. 2016;8(S1):S96.

Nakagawa M, Matsuya S, Koich U. Corrosion behavior of pure titanium and titanium alloys in fluoride-containing solutions. Dent Mater J. 2001;20(4):305.

Huang H-H. Effect of fluoride and albumin concentration on the corrosion behavior of Ti–6Al–4V alloy. Biomaterials. 2003;24(2):275.

Huang HH. Effects of fluoride concentration and elastic tensile strain on the corrosion resistance of commercially pure titanium. Biomaterials. 2002;23(1):59.

Souza J, Barbosa S, Ariza E, Celis JP, Rocha L. Simultaneous degradation by corrosion and wear of titanium in artificial saliva containing fluorides. Wear. 2012;292:82.

Luo P, Wang S, Zhao T, Li Y. Surface characteristics, corrosion behavior, and antibacterial property of Ag-implanted NiTi alloy. Rare Met. 2013;32(2):113.

Shirai T, Tsuchiya H, Shimizu T, Ohtani K, Zen Y, Tomita K. Prevention of pin tract infection with titanium-copper alloys. J Biomed Mater Res B Appl Biomater. 2009;91(1):373.

Zhang E, Li F, Wang H, Liu J, Wang C, Li M, Yang K. A new antibacterial titanium–copper sintered alloy: preparation and antibacterial property. Mater Sci Eng, C. 2013;33(7):4280.

Zhang E, Ren J, Li S, Yang L, Qin G. Optimization of mechanical properties, biocorrosion properties and antibacterial properties of as-cast Ti–Cu alloys. Biomed Mater. 2016;11(6):065001.

Zhang E, Wang X, Chen M, Hou B. Effect of the existing form of Cu element on the mechanical properties, bio-corrosion and antibacterial properties of Ti–Cu alloys for biomedical application. Mater Sci Eng, C. 2016;69:1210.

Ren L, Ma Z, Li M, Zhang Y, Liu W, Liao Z, Yang K. Antibacterial properties of Ti–6Al–4V–xCu alloys. J Mater Sci Technol. 2014;30(7):699.

Chern Lin JH, Moser JB, Taira M, Greener EH. Cu–Ti, Co–Ti and Ni–Ti systems: corrosion and microhardness. J Oral Rehabil. 1990;17(4):383.

Liu J, Li F, Liu C, Wang H, Ren B, Yang K, Zhang E. Effect of Cu content on the antibacterial activity of titanium-copper sintered alloys. Mater Sci Eng C-Mater Biolog Appl. 2014;35:392.

Taira M, Moser JB, Greener EH. Studies of Ti alloys for dental castings. Dent Mater. 1989;5(1):45.

Bai B, Zhang E, Dong H, Liu J. Biocompatibility of antibacterial Ti–Cu sintered alloy: in vivo bone response. J Mater Sci-Mater Med. 2015;26(12):265.

Liu J, Zhang X, Wang H, Li F, Li M, Yang K, Zhang E. The antibacterial properties and biocompatibility of a Ti–Cu sintered alloy for biomedical application. Biomed Mater. 2014;9(2):25013.

Takahashi M, Kikuchi M, Takada Y, Okuno O. Mechanical properties and microstructures of dental cast Ti–Ag and Ti–Cu alloys. Dent Mater J. 2002;21(3):270.

Kikuchi M, Takada Y, Kiyosue S, Yoda M, Woldu M, Cai Z, Okuno O, Okabe T. Mechanical properties and microstructures of cast Ti–Cu alloys. Dent Mater. 2003;19(3):174.

Ohkubo C, Shimura I, Aoki T, Hanatani S, Hosoi T, Hattori M, Oda Y, Okabe T. Wear resistance of experimental Ti–Cu alloys. Biomaterials. 2003;24(20):3377.

Kikuchi M, Takahashi M, Okabe T, Okuno O. Grindability of dental cast Ti–Ag and Ti–Cu alloys. Dent Mater J. 2003;22(2):191.

Hattori M, Kaku S, Hasegawa K, Kawada E, Oda Y, Okabe T. Casting accuracy of experimental Ti–Cu alloys. J Dent Res. 2000;79:416.

Mutlu I, Oktay E. Characterization of 17-4 PH stainless steel foam for biomedical applications in simulated body fluid and artificial saliva environments. Mater Sci Eng, C. 2013;33(3):1125.

Bao M, Liu Y, Wang X, Yang L, Li S, Ren J, Li S, Yang L, Qin G, Zhang E. Optimization of mechanical properties, biocorrosion properties and antibacterial properties of wrought Ti–3Cu alloy by heat treatment. Bioact Mater. 2018;3(1):28.

Chaturvedi T. An overview of the corrosion aspect of dental implants (titanium and its alloys). Indian J Dent Res. 2009;20(1):91.

Tomashov N, Altovsky R, Chernova G. Passivity and corrosion resistance of titanium and its alloys. J Electrochem Soc. 1961;108(2):113.

Hickman J, Gulbransen E. Oxide films formed on titanium, zirconium, and their alloys with nickel, copper, and cobalt. Anal Chem. 1948;20(2):158.

Virtanen S, Milošev I, Gomez-Barrena E, Trebše R, Salo J, Konttinen Y. Special modes of corrosion under physiological and simulated physiological conditions. Acta Biomater. 2008;4(3):468.

Morcillo M, Diaz I, Chico B, Cano H, de la Fuente D. Weathering steels: from empirical development to scientific design. A review. Corros Sci. 2014;83:6.

Sun Q, Yu Z, Zhu R. Dynamic fracture toughness of Ti–2.5Cu alloy strengthened with nano-scale particles at room and low temperatures. Mater Sci Eng, A. 2008;483:131.

Liu J, Li F, Liu C, Wang H, Ren B, Yang K, Zhang E. Effect of Cu content on the antibacterial activity of titanium–copper sintered alloys. Mater Sci Eng, C. 2014;35:392.

Osório WR, Cremasco A, Andrade PN, Garcia A, Caram R. Electrochemical behavior of centrifuged cast and heat treated Ti–Cu alloys for medical applications. Electrochim Acta. 2010;55(3):759.

Davis JR. Copper and Copper Alloys. Cleveland: ASM International; 2001. 13.

Santo CE, Lam EW, Elowsky CG, Quaranta D, Domaille DW, Chang CJ, Grass G. Bacterial killing by dry metallic copper surfaces. Appl Environ Microbiol. 2011;77(3):794.

Cakmak H, Taylor HS. Implantation failure: molecular mechanisms and clinical treatment. Hum Reprod Update. 2011;17(2):242.

Brewer GJ. Risks of copper and iron toxicity during aging in humans. Chem Res Toxicol. 2010;23(2):319.

Cao B, Zheng Y, Xi T, Zhang C, Song W, Burugapalli K, Yang H, Ma Y. Concentration-dependent cytotoxicity of copper ions on mouse fibroblasts in vitro: effects of copper ion release from TCu380A vs TCu220C intra-uterine devices. Biomed Microdevice. 2012;14(4):709.

Bennett MR, Anglin S, Mcewan JR, Jagoe R, Newby AC, Evan GI. Inhibition of vascular smooth muscle cell proliferation in vitro and in vivo by c-myc antisense oligodeoxynucleotides. J Clin Investig. 1994;93(2):820.

Gérard C, Bordeleau LJ, Barralet J, Doillon CJ. The stimulation of angiogenesis and collagen deposition by copper. Biomaterials. 2010;31(5):824.

Zhang E, Zheng L, Liu J, Bai B, Liu C. Influence of Cu content on the cell biocompatibility of Ti–Cu sintered alloys. Mater Sci Eng, C. 2015;46:148.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 81071262 and 31271024), the Funding from Northeastern University, China (Nos. N141008001 and LZ2014018) and Beijing Municipal Natural Science Foundation (No. 7161001).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Cai, DG., Bao, MM., Wang, XY. et al. Biocorrosion properties of Ti–3Cu alloy in F ion-containing solution and acidic solution and biocompatibility. Rare Met. 38, 503–511 (2019). https://doi.org/10.1007/s12598-019-01202-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01202-9