Abstract

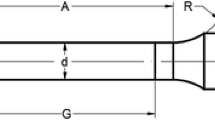

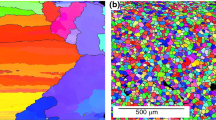

It has been reported that the element scandium (Sc) is the most effective modificator which can significantly refine the grain size, prohibit recrystallization process and increase the strength. Adding trace of Sc in 7000 series aluminum alloys is considered to be an effective way to modify its microstructure and promote mechanical properties. In order to study the effect of Sc element on as-cast microstructure of Al–Zn–Mg–Cu–Zr alloy, ingots containing different amounts of Sc were prepared by ferrous-mold cast. Microstructures were characterized by means of differential scanning calorimeter (DSC), X-ray diffraction (XRD), optical microscope (OM) and scanning electrical microscope (SEM). The results indicate that when the Sc level exceeds a critical concentration, Al3(Sc,Zr) primary phase would form in the melt and act as an efficient nucleant, resulting in very refined grain and an equiaxed grain structure. Sc element reduces the number of eutectic phases formed during solidification, coupled with an increase in the concentration of major alloying elements retained in the solute. This behavior suggests possible benefits in improving the integrated properties of terminal products.

Similar content being viewed by others

References

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS. Recent development in aluminium alloys for aerospace applications. Mater Sci Eng A. 2000;280(1):102.

Warner T. Recently-developed aluminium solutions for aerospace applications. Mater Sci Forum. 2006;519–521:1271.

Liu J. Advanced aluminium and hybrid aerostructures for future aircraft. Mater Sci Forum. 2006;519–521:1233.

Fridlyander IN. Russian aluminum alloys for aerospace and transport applications. Mater Sci Forum. 2000;331–337:921.

Nakai M, Eto T. New aspect of development of high strength aluminum alloys for aerospace applications. Mater Sci Eng A. 2000;285(1–2):62.

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des. 2014;56:862.

Su JQ, Nelson TW, Mishra R, Mahoney M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003;51(3):713.

Dumont M, Steuwer A, Deschamps A, Peel M, Withers P. Microstructure mapping in friction stir welds of 7449 aluminium alloy using SAXS. Acta Mater. 2006;54(18):4793.

Zhao Y, Lu Z, Yan K, Huang L. Microstructural characterizations and mechanical properties in underwater friction stir welding of aluminum and magnesium dissimilar alloys. Mater Des. 2015;65:675.

Malarvizhi S, Balasubramanian V. Fatigue crack growth resistance of gas tungsten arc, electron beam and friction stir welded joints of AA2219 aluminium alloy. Mater Des. 2011;32(3):1205.

Norman AF, Hyde K, Costello F, Thompson S, Birley S, Prangnell PB. Examination of the effect of Sc on 2000 and 7000 series aluminium alloy castings: for improvements in fusion welding. Mater Sci Eng A. 2003;354(1–2):188.

He YD, Zhang XM, You JH. Effect of minor Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy. Trans Nonferr Met Soc China. 2006;16(5):1228.

Huang X, Pan QL, Li B, Liu ZM, Huang ZQ, Yin ZM. Effect of minor Sc on microstructure and mechanical properties of Al–Zn–Mg–Zr alloy metal–inert gas welds. J Alloys Compd. 2015;629:197.

Deng Y, Peng B, Xu GF, Pan QL, Yin ZM, Ye R, Wang YJ, Lu Y. Effects of Sc and Zr on mechanical property and microstructure of tungsten inert gas and friction stir welded aerospace high strength Al–Zn–Mg alloys. Mater Sci Eng A. 2015;639:500.

Milman YV, Sirko AI, Lotsko DV, Senkov ON, Miracle DB. Microstructure and mechanical properties of cast and wrought Al-Zn-Mg-Cu alloys modified with Zr and Sc. Mater Sci Forum. 2002;396–402:1217.

Mukhopadhyay AK, Kumar A, Raveendra S, Samajdar I. Development of grain structure during superplastic deformation of an Al–Zn–Mg–Cu–Zr alloy containing Sc. Scripta Mater. 2011;64(5):386.

Meng Y, Zhao ZH, Cui JZ. Effect of minor Zr and Sc on microstructures and mechanical properties of Al–Mg–Si–Cu–Cr–V alloys. Trans Nonferr Met Soc China. 2013;23(7):1882.

Liu J, Yao P, Zhao N, Shi C, Li H, Li X, Xi DS, Yang S. Effect of minor Sc and Zr on recrystallization behavior and mechanical properties of novel Al–Zn–Mg–Cu alloys. J Alloys Compd. 2016;657:717.

Yin ZM, Pan QL, Zhang YH, Jiang F. Effect of minor Sc and Zr on the microstructure and mechanical properties of Al–Mg based alloys. Mater Sci Eng A. 2000;280(1):151.

Gschneidner KA, Calderwood FW. The AI-Sc (aluminum-scandium) system. Bull Alloy Phase Diagr. 1989;10(1):34.

Norman AF, Prangnell PB, McEwen RS. The solidification behaviour of dilute aluminium–scandium alloys. Acta Mater. 1998;46(16):5715.

Li JH, Oberdorfer B, Wurster S, Schumacher P. Impurity effects on the nucleation and growth of primary Al3(Sc,Zr) phase in Al alloys. J Mater Sci. 2014;49(17):5961.

Elagin VL, Zakharov VV, Rostova TD. Scandium alloyed aluminum alloys. Met Sci Heat Treat. 1992;34(1):37.

Zhang W, Xing Y, Jia ZH, Yang XF, Liu Q, Zhu CL. Effect of minor Sc and Zr addition on microstructure and properties of ultra-high strength aluminum alloy. Trans Nonferr Met Soc China. 2014;24(12):3866.

Costello FA, Robson JD, Prangnell PB. The Effect of small scandium Additions to AA7050 on the as-cast and homogenized microstructure. Mater Sci Forum. 2002;396–402:757.

Blake N, Hopkins MA. Constitution and age hardening of Al-Sc alloys. J Mater Sci. 1985;20(8):2861.

Rokhlin LL, Dobatkina TV, Bochvar NR, Lysova EV. Investigation of phase equilibria in alloys of the Al–Zn–Mg–Cu–Zr–Sc system. J Alloys Compd. 2004;367(1–2):10.

Røyset J, Ryum N. Scandium in aluminium alloys. Int Mater Rev. 2013;50(1):19.

Li JH, Wiessner M, Albu M, Wurster S, Sartory B, Hofer F, Schumacher P. Correlative characterization of primary Al3(Sc,Zr) phase in an Al–Zn–Mg based alloy. Mater Charact. 2015;102:62.

Li WB, Pan QL, Xiao YP, He YB, Liu XY. Microstructural evolution of ultra-high strength Al-Zn-Cu-Mg-Zr alloy containing Sc during homogenization. Trans Nonferr Met Soc China. 2011;21(10):2127.

Acknowledgements

This study was financially supported by the National Key Research and Development Program of China (No. 2016YFB0300903).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Xiong, BQ., Li, ZH. et al. As-cast microstructure of Al–Zn–Mg–Cu–Zr alloy containing trace amount of Sc. Rare Met. 38, 343–349 (2019). https://doi.org/10.1007/s12598-018-1136-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1136-5