Abstract

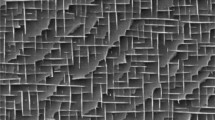

The effect of Mo and Al addition on the microstructure as well as creep rupture properties at 760 °C/850 MPa was investigated by transmission electron microscopy (TEM) in a Ni-based single-crystal (SC) alloy with the composition of Ni–6.5Al–8.0Mo–2.4Cr–6.2Ta–4.9Co–1.5Re–(0.01–0.05)Y (wt%). The microstructure analysis shows that 0.5 wt% Al addition induces rapid decrease in creep rupture life, and this can be attributed to the formation of dense stacking faults cutting into γ′ precipitates, which can be explained by the increase in Orowan stress caused by the narrower γ channel width and the decrease in stacking faults energy. Besides, 1.5 wt% Mo addition increases the anti-phase boundary energy and decreases the stacking faults energy, resulting in fewer stacking faults and thus a slight decrease in the creep rupture life.

Similar content being viewed by others

References

Reed RC. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press; 2008. 2.

Heckl A, Neumeier S, Göken M, Singer RF. The effect of Re and Ru on γ/γ′ microstructure, γ-solid solution strengthening and creep strength in nickel-base superalloys. Mater Sci Eng A. 2011;528(9):3435.

Yeh AC, Tin S. Effects of Ru and Re additions on the high temperature flow stresses of Ni-base single crystal superalloys. Scr Mater. 2005;52(6):519.

Ma S, Carroll L, Pollock TM. Development of γ phase stacking faults during high temperature creep of Ru-containing single crystal superalloys. Acta Mater. 2007;55(17):5802.

Reed RC, Tao T, Warnken N. Alloys-by-design: application to nickel-based single crystal superalloys. Acta Mater. 2009;57(19):5898.

Kondo Y, Kubo Y, Miura N, Murata Y, Yoshinari A. Creep properties of a new Re free single crystal Ni-based superalloy. MATEC Web Conf. 2014;14:20003.

Mottura A, Reed RC. What is the role of rhenium in single crystal superalloys. MATEC Web Conf. 2014;14:01001.

MacKay RA, Gabb TP, Smialek JL, Nathal MV. A new approach of designing superalloys for low density. JOM. 2010;62(1):48.

Zhao H, Li S, Pei YL, Gong SK, Xu HB. Microstructure and mechanical properties of Ni3Al-based single crystal alloy IC21. Acta Metall Sin. 2015;51(10):1279.

Agudo JL, Eggeler G, Dlouhý A. Advanced scanning transmission stereo electron microscopy of structural and functional engineering materials. Ultramicroscopy. 2012;122(11):48.

Wu X, Wollgramm P, Somsen C, Dlouhy A, Kostka A, Eggeler G. Double minimum creep of single crystal Ni-base superalloys. Acta Mater. 2016;112:242.

Liang Y, Li S, Ai C, Han Y, Gong SK. Effect of Mo content on microstructure and stress-rupture properties of a Ni-base single crystal superalloy. Prog Nat Sci Mater Int. 2016;26(1):112.

Harada H, Yamazaki M, Koizumi Y, Sakuma N, Furuya N, Kamiya H. Alloy design for nickel-base superalloys. In: Brunetaud R, Coutsouradis D, Gibbons TB, Lindblom Y, Meadowcroft DB, Stickler R, editors. High Temperature Alloys for Gas Turbines. Berlin: Springer; 1982. 721.

Ro Y, Koizumi Y, Harada H. High temperature tensile properties of a series of nickel-base superalloys on a γ/γ′ tie line. Mater Sci Eng A. 1997;223(4):59.

Murakumo T, Kobayashi T, Koizumi Y, Harada H. Creep behaviour of Ni-base single-crystal superalloys with various γ′ volume fraction. Acta Mater. 2004;52(12):3737.

Cottrell AH, Seeger A, Amorós JL. Dislocations in crystals. In: Grammel R, editor. Deformation and Flow of Solids. Berlin: Springer; 1956. 33.

Yuan Y, Kawagishi K, Koizumi Y, Kobayashi T, Yokokawa T, Harada H. Creep deformation of a sixth generation Ni-base single crystal superalloy at 800 °C. Mater Sci Eng A. 2014;608:95.

Kear BH, Oblak JM, Giamei AF. Stacking faults in gamma prime Ni3(Al, Ti) precipitation hardened nickel-base alloys. Metall Mater Trans B. 1970;1(9):2477.

Diologent F, Caron P. On the creep behavior at 1033 K of new generation single-crystal superalloys. Mater Sci Eng A. 2004;385(1):245.

Leverant GR, Kear BH, Oblak JM. Creep of precipitation-hardened nickel-base alloy single crystals at high temperatures. Metall Mater Trans B. 1973;4(1):355.

Rae CMF, Matan N, Reed RC. The role of stacking fault shear in the primary creep of [001]-oriented single crystal superalloys at 750 °C and 750 MPa. Mater Sci Eng A. 2001;300(1):125.

Vorontsov VA, Kovarik L, Mills MJ, Rae CMF. High resolution electron microscopy of dislocation ribbons in a CMSX-4 superalloy single crystal. Acta Mater. 2012;60(12):4866.

Rae CMF, Reed RC. Primary creep in single crystal superalloys: origins, mechanisms and effects. Acta Mater. 2007;55(3):1067.

Pollock TM, Field RD. Dislocations and high-temperature plastic deformation of superalloy single crystals. In: Nabarro FRN, Duesbery MS, editors. Dislocations in Solids. Amsterdam: Elsevier Sciences; 2002. 547.

Matan N, Cox DC, Carter P, Rist MA, Rae CMF, Reed RC. Creep of CMSX-4 superalloy single crystals: effects of misorientation and temperature. Acta Mater. 1999;47(5):1549.

Abel CA. The physics of creep. Mater Des. 1996;17(1):53.

Kear BH, Giamei AF, Leverant GR, Oblak JM. On intrinsic/extrinsic stacking fault pairs in the Ll2 lattice. Scr Metall. 1969;3(2):123.

Condat M, Décamps B. Shearing of γ′ precipitates by single a/2<110> matrix dislocations in a γ/γ′ Ni-based superalloy. Scr Metall. 1987;21(5):607.

Décamps B, Morton AJ, Condat M. On the mechanism of shear of γ′ precipitates by single (a/2)<110> dissociated matrix dislocations in Ni-based superalloys. Philos Mag A. 1991;64(3):641.

Rae CMF, Rist MA, Cox DC, Reed RC, Matan N. On the primary creep of CMSX-4 superalloy single crystals. Metall Mater Trans A. 2000;31(9):2219.

Pollock TM, Argon AS. Creep resistance of CMSX-3 nickel base superalloy single crystals. Acta Metall Mater. 1992;40(1):1.

Gypen LA, Deruyttere A. Multi-component solid solution hardening. J Mater Sci. 1977;12(5):1034.

Roth HA, Davis CL, Thomson RC. Modeling solid solution strengthening in nickel alloys. Metall Mater Trans A. 1997;28(6):1329.

Mishima Y, Ochiai S, Hamao N, Yodogawa M, Suzuki T. Solid solution hardening of nickel role of transition metal and B-subgroup solute. Trans Jpn Inst Metals. 1986;27(9):656.

Veyssière P, Saada G. Microscopy and plasticity of the L12 γ phase. In: Nabarro FRN, Duesbery MS, editors. Dislocations in Solids. Amsterdam: Elsevier Sciences; 1996. 253.

Sondhi SK, Chandran M. First-principle calculation of APB energy in Ni-based binary and ternary alloys. Modell Simul Mater Sci Eng. 2011;19(2):7.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 51101004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, PS., Wang, H., Ru, Y. et al. Microstructure and creep properties of Ni-based single-crystal superalloys with Mo/Al addition at 760 °C/850 MPa. Rare Met. 42, 3806–3813 (2023). https://doi.org/10.1007/s12598-018-1094-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1094-y