Abstract

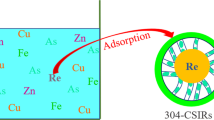

In this paper, a weak-base resin was adopted to recycle rhenium because of its excellent adsorption and desorption properties for rhenium, while the kinetics and thermodynamics properties of adsorbing rhenium from the rhenium stock solution were systematically investigated. The kinetics investigations confirm that the adsorption process of Re belongs to kinetic control by particle diffusion process and the corresponding reaction rate constant is 2.68 × 10−3 s−1. Then, the Langmuir and Freundlich models were used to describe the adsorption equilibrium behaviors of Re and the thermodynamics parameters are obtained. The results show that the Langmuir model is the best-fitted model, and the Gibbs free energy change of Re adsorption onto ZS15 weak-base resin is ∆G0 = − 10.59 + 12.66T. To verify the weak-base resins for extracting rhenium in industrial application, the column experiments were operated in the spray solution generating by roasting the molybdenum concentrates. The results indicate that the weak-base resins possess excellent adsorptive selectivity for rhenium, and the ammonia solution with low concentration could sufficiently desorb rhenium from the resins.

Similar content being viewed by others

References

Huang M, Zhu J. An overview of rhenium effect in single-crystal superalloys. Rare Met. 2016;35(2):502.

Abisheva ZS, Zagorodnyaya AN. Hydrometallurgy in rare metal production technology in Kazakhstan. Hydrometallurgy. 2002;63(1):55.

Liu EZ, Guan XR, Zheng Z. Effect of rhenium on solidification and segregation of nickel-based superalloy. Rare Met. 2011;30(1):320.

Giamei AF, Anton DL. Rhenium additions to a Ni-base superalloy: effects on microstructure. Metall Trans A. 1985;16(11):1997.

Huang C, Chen QS, Li Y, Liu QY. Discussion of world and China rhenium resource demand in 2030. China Min Mag. 2014;23(9):9.

Lan X, Liang S, Song Y. Recovery of rhenium from molybdenite calcine by a resin-in-pulp process. Hydrometallurgy. 2006;82(3–4):133.

Anderson CD, Taylor PR, Anderson CG. Extractive metallurgy of rhenium: a review. Miner Metall Process. 2013;30(1):59.

Abisheva ZS, Zagorodnyaya AN, Bekturganov NS. Review of technologies for rhenium recovery from mineral raw materials in Kazakhstan. Hydrometallurgy. 2011;109(1):1.

Gode F, Pehlivan E. A comparative study of two chelating ion-exchange resins for the removal of chromium (III) from aqueous solution. J Hazard Mater. 2003;100(1–3):231.

Kholmogorov AG, Kononova ON, Kachin SV, Ilyichev SN, Kryuchkov VV, Kalyakina OP, Pashkov GL. Ion exchange recovery and concentration of rhenium from salt solution. Hydrometallurgy. 1999;51(1):19.

Zou ZQ, Zhou QJ. Recovery of molybdenum and rhenium from molybdenite concentrate in Dexing copper ore by lime roasting-N235 extraction method. Min Metall Eng. 2002;22(2):79.

Cao ZF, Zhong H, Qiu ZH. Solvent extraction of rhenium from molybdenum in alkaline solution. Hydrometallurgy. 2009;97(3–4):153.

Gerhardt NI, Palant AA, Dungan SR. Extraction of tungsten (VI), molybdenum (VI) and rhenium (VII) by diisododecylamine. Hydrometallurgy. 2000;55(1):1.

Lou ZN, Li YE, Ren FQ, Zhang Q, Wan L, Xing ZQ, Zang SL, Xiong Y. Selectivity recovery of molybdenum (VI) from rhenium (VII) by amine-modified persimmon waste. Rare Met. 2016;35(6):502.

Gerhardt NI, Palant AA, Petrova VA, Tagirov RK. Solvent extraction of molybdenum (VI), tungsten (VI) and rhenium (VII) by diisododecylamine from leach liquors. Hydrometallurgy. 2001;60(1):1.

Mozammel M, Sadrnezhaad SK, Badami E, Ahmadi E. Break-through curves for adsorption and elution of rhenium in a column ion exchange system. Hydrometallurgy. 2007;85(1):17.

Liu Y, Deng L, Liu L, Zhou YZ, Chang YL. Adsorption of Re from electrolyte of superalloy by using D296 resin. Chin J Rare Met. 2017;41(6):678.

Shariat MH, Hassani M. Rhenium recovery from Sarcheshmeh molybdnite concentrate. J Mater Process Technol. 1998;74(1–3):243.

Xiong CH, Yao CP, Wu XM. Adsorption of rhenium (VII) on 4-amino-1,2,4-triazone resin. Hydrometallurgy. 2008;90(2–4):221.

Zagorodnyaya AN, Abisheva ZS, Sharipova AS, Sasykanova SE, Bochevskaya YG, Atanova OV. Sorption of rhenium and uranium by strong base anion exchange resin from solutions with different anion compositions. Hydrometallurgy. 2013;131–132(s 131–132):127.

Xiong CH, Yao CP, Wu XM. Adsorption of rhenium(VII) on 4-amino-1,2,4-triazole resin. Hydrometallurgy. 2008;90(2–4):221.

Liu HZ, Wang LJ, Zhang B, Wang W. Static adsorption properties of a kind of weak anion ion resin for rhenium in spraying water. Chinese Journal of Rare Metals. 2017;41(9):1028.

Jiang KX, Deng GC, Zhang Q, Zhang J, Zhai YC. Experi-mental research on the static separation of rhenium from molybdenum with D314 resin. Rare Met Cem Carbides. 2011;39(1):8.

He HJ, Wang XS, Yang ZC. Separation of Re(VII) and Mo(VI) by D301 macroporous weakly basic resin. Uranium Min Metall. 1990;9(1):37.

Zhao Z, Li XB, Zhao QJ. Kinetics research on recovery of vanadium from Bayer process by ion exchange with resin. Chin J Process Eng. 2009;9(3):462.

Zhao ZW, Xu XY, Chen XY, Huo GS, Chen AL, Liu XH, Xu H. Thermodynamics and kinetics of adsorption of molybdenum blue with D301 ion exchange resin. Trans Nonferrous Metals Soc China. 2012;22(3):686.

Song X, Du H, Liu S, Qian H. Adsorption properties of Ni(II) by D301R anion exchange resin. J Chem. 2014;2014(5–6):1.

Xiong Y, Xu J, Shan WJ, Lou ZN, Fang DW, Zang SL, Han GX. A new approach for rhenium (VII) recovery by using modified brown algae laminaria japonica adsorbent. Biores Technol. 2013;127(1):464.

Zhou YX, Lei P, Fei YQ, Pan Q, Liu Y. Thermodynamics and kinetics of ion exchange resin adsorption iron ions of dilute sulfuric acid. J Wuhan Inst Technol. 2012;34(9):9.

Zhao ZW, Xu XY, Chen XY, Huo GS, Chen AL, Liu XH, Xu H. Thermodynamics and kinetics of adsorption of molybdenum blue with D301 ion exchange resin. Trans Nonferrous Met Soc China. 2012;22(3):686.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (Nos. 51404220 and 51504225).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, HZ., Zhang, B., Jing, XJ. et al. Adsorption and desorption properties for rhenium using a kind of weak-base anion resin. Rare Met. 37, 707–715 (2018). https://doi.org/10.1007/s12598-018-1077-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-018-1077-z