Abstract

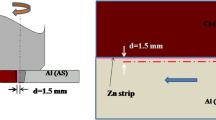

In this study, 5052 aluminum alloy and Q235 steel were joined by a new way of arc milling brazing, with the Zn15%Al filler metal and no use of flux. Effect of rotation speed on mechanical properties and microstructure of joint interface was investigated. The results show that increasing rotation speed is in favor of formation of weld and spread of filler metal on substrate. The fine grain with homogeneous composition in brazed seam can be realized by the stronger stirring in pool induced by milling at more higher rotation speed. And, a composite joint reinforced with needle-like or block-like Fe–Al–Zn intermetallic compounds (IMCs) particle can be obtained by arc milling brazing, which comes from the reaction between steel scrape and Zn–Al filler alloy. The test on strength of joint interface shows that with the increase in rotation speed, there is a peak value in variation ranges of strength of joint interface. This is to say, when rotation speed is 2720 r·min−1, the strength of joint has maximum value (182.01 MPa). Moreover, a thin and discontinuous IMCs layer at joint interface can be obtained by increasing rotation speed. But at a low or high rotation speed, there also is a crack at joint interface, which weakens the strength of joint interface. Only at 2720 r·min−1, a good joint interface without an obvious crack can be realized.

Similar content being viewed by others

References

Mazar Atabaki M, Nikodinovski M, Chenier P, Ma J, Harooni M, Kovacevic R. Welding of aluminum alloys to steels: an overview. J Manuf Sci Prod. 2014;14(2):59.

Torkamany MJ, Tahamtan S, Sabbaghzadeh J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser. Mater Des. 2010;31(1):458.

Yang SL, Zhang J, Lian J, Lei YG. Welding of aluminum alloy to zinc coated steel by cold metal transfer. Mater Des. 2013;49(8):602.

Ezazi MA, Yusof F, Sarhan AAD, Shukor MHA, Fadzi M. Employment of fiber laser technology to weld austenitic stainless steel 304l with aluminum alloy 5083 using pre-placed activating flux. Mater Des. 2015;87(12):105.

Nguyen QM, Huang SC. An investigation of the microstructure of an intermetallic layer and toughness in welding aluminum/steel by TIG process. Adv Mater Sci Eng. 2015;8(12):8246.

Borrisutthekul R, Mitsomwang P, Rattanachan S, Mutoh Y. Feasibility of using TIG welding in dissimilar metals between steel/aluminum alloy. Energy Res J. 2010;1(2):82.

Gao M, Chen C, Mei SW, Wang L, Zeng XL. Parameter optimization and mechanism of laser-arc hybrid welding of dissimilar Al alloy and stainless steel. Int J Adv Manuf Technol. 2014;74(1):199.

Liu X, Lan SH, Ni J. Analysis of process parameters effects on friction welding process of dissimilar aluminum alloy to advanced high strength steel. Mater Des. 2014;59(6):50.

Coelho RS, Kostka A, Santos JFD, Kaysser-Pyzalla A. Friction-stir dissimilar welding of aluminium alloy to high strength steels: mechanical properties and their relation to microstructure. Mater Sci Eng A. 2012;556(10):175.

Dehghani M, Amadeh A, Mousavi SAAA. Investigations on the effects of friction stir welding parameters on intermetallic and defect formation in joining aluminum alloy to mild steel. Mater Des. 2013;49(6):433.

López EAT, Ramirez AJ. Effect of process parameters in obtaining aluminium–steel joints and their microstructure by friction stir welding (FSW). Weld Int. 2015;29(9):689.

Elrefaey A, Gouda M, Takahashi M, Ikeuchi K. Characterization of aluminum/steel lap joint by friction stir welding. J Mater Eng Perform. 2005;14(1):10.

Karfoul MK, Tatlock GJ, Murray RT. The behaviour of iron and aluminium during the diffusion welding of carbon steel to aluminium. J Mater Sci. 2007;42(14):5692.

Cheng XL, Bai BZ, Gao YM, Feng C. Microstructural characterization of the Al/Cu/steel diffusion bonded joint. Rare Met. 2009;28(5):478.

Munoz-Guijosa JM, Nanaumi G, Ohtani K, Ohtake N. Perpendicular ultrasonic joining of steel to aluminium alloy plates. J Mater Process Technol. 2017;243(5):112.

Farid H. Microstructure reaction control of dissimilar automotive aluminium to galvanized steel sheets ultrasonic spot welding. Mater Sci Eng A. 2016;678(12):72.

Farid H, Fadi AF. The effect of interface reaction on vibration evolution and performance of aluminium to steel high power ultrasonic spot joints. Mater Des. 2016;899(1):50.

Huang JK, He J, Yu XQ, Li CL, Fan D. The study of mechanical strength for fusion-brazed butt joint between aluminum alloy and galvanized steel by arc-assisted laser welding. J Manuf Process. 2017;25(1):126.

Li CL, Fan D, Wang B. Characteristics of TIG arc-assisted laser welding–brazing joint of aluminum to galvanized steel with preset filler powder. Rare Met. 2015;34(9):650.

Zhang Y, Guo GL, Li FN, Wang G, Wei HY. The interface control of butt joints in laser braze welding of aluminium-steel with coaxial powder feeding. J Mater Process Technol. 2017;246(8):313.

Guillaume F, Mohamed EM, Lucio T, Sabeur M. Industrial fluxless laser weld-brazing process of steel to aluminium at high brazing speed. J Manuf Process. 2017;25(1):104.

Dong HG, Yang LQ, Dong C, Kou S. Arc joining of aluminum alloy to stainless steel with flux-cored Zn-based filler metal. Mater Sci Eng A. 2010;527(26):7151.

Yagati KP, Bathe RN, Rajulapati KV, Rao KBS, Padmanabham G. Fluxless arc weld-brazing of aluminium alloy to steel. J Mater Process Technol. 2014;214(12):2949.

Shao L, Shi Y, Huang JK, Wu SJ. Effect of joining parameters on microstructure of dissimilar metal joints between aluminum and galvanized steel. Mater Des. 2015;66(2):453.

He H, Lin SB, Yang CL, Fan CL, Chen Z. Combination effects of Nocolok flux with Ni powder on properties and microstructures of aluminum-stainless steel TIG welding–brazing joint. J Mater Eng Perform. 2013;22(11):3315.

He H, Yang CL, Chen Z, Lin SB, Fan CL. Strength prediction of aluminum-stainless steel-pulsed TIG welding–brazing joints with RSM and ANN. Acta Metall Sin. 2014;27(6):1012.

Ye Z, Huang JH, Gao W, Zhang YF, Cheng Z, Chen SH, Yang J. Microstructure and mechanical properties of 5052 aluminum alloy/mild steel butt joint achieved by MIG-TIG double-sided arc welding-brazing. Mater Des. 2017;123(6):69.

Zhang YF, Huang JH, Cheng Z, Ye Z, Chi H, Li P, Chen SH. Study on MIG-TIG double-sided arc welding–brazing of aluminum and stainless steel. Mater Lett. 2016;172(6):146.

Dong HG, Hu WJ, Duan YP, Wang XD, Dong C. Dissimilar metal joining of aluminum alloy to galvanized steel with Al–Si, Al–Cu, Al–Si–Cu and Zn–Al filler wires. J Mater Process Technol. 2012;212(2):458.

Su YC, Hua XM, Wu YX. Effect of input current modes on intermetallic layer and mechanical property of aluminum–steel lap joint obtained by gas metal arc welding. Mater Sci Eng A. 2013;578(8):340.

Zoqui EJ, Paes M, Robert MH. Effect of macrostructure and microstructure on the viscosity of the A356 alloy in the semi-solid state. J Mater Process Technol. 2004;153–154(1):303.

Baker H. ASM Handbook: Alloy Phase Diagrams, vol. 3. Ohio: Materials Park; 1992. 73.

Acknowledgements

This work was financially supported by the State Key Laboratory of Advanced Welding and Joining of China (No. AWJ-Z16-02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, HB., Tang, S., Xi, HF. et al. Joint interface during arc milling brazing of aluminum alloy to low carbon steel with cutter milling at various rotation speeds. Rare Met. 36, 872–877 (2017). https://doi.org/10.1007/s12598-017-0957-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0957-y