Abstract

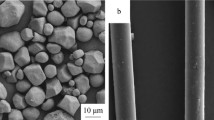

The forming process and mechanism of the reaction of Ti–6Al–4V investment casting made by Zr(CH3COO)2-Y2O3 shell in vacuum casting was studied. Statistic was manipulated to study the distributions and types of the reaction layers. The morphology and composition of the reaction layers were tested using field emission scanning electron microscopy (FESEM) combined with energy-dispersive spectroscopy (EDS). Phase of the reaction layers was characterized by X-ray diffraction (XRD). Composition of the shell reaction zone was measured by X-ray fluorescence (XRF) method. The results suggest the reaction contains oxidation and element evaporation, and the melt reacts little with the shell but mainly with the remnant gas. The reaction layers contain three types due to different forming stages: the titanium oxidation film, the concretion film and the shell reaction zone. The interfacial temperature and pressure affect the reaction mechanism and degree, leading to three types of concretion films that differ in thickness, content and color.

Similar content being viewed by others

References

Shah FA, Trobos M, Thomsen P, Palmquist A. Commercially pure titanium (CP–Ti) versus titanium alloy (Ti6Al4V) materials as bone anchored implants—is one truly better than the other? Review. Mater Sci Eng, C. 2016;62:960.

Bob H. Titanium use in aerospace applications. Ind Heat. 2007;74(11):57.

Saha RL, Jacob KT. Casting of titanium and its alloys. Def Sci J. 2014;36(2):121.

Sung SY, Kim YJ. Alpha-case formation mechanism on titanium investment castings. Mater Sci Eng A. 2005;405(1):173.

Nastac L, Gungor MN, Klug KL, Tack WT. Advances in investment casting of Ti–6Al–4V alloy: a review. Int J Cast Met Res. 2006;19(2):73.

Liu AH. The interfacial reaction law and micromechanism between titanium alloy melts and ceramic mould. Harbin: Harbin Institute of Technology; 2007. 30.

Xiao SL. Study on technology of investment cast for titanium alloy using low cost oxide ceramic mould shell. Harbin: Harbin Institute of Technology; 2007. 48.

Cotton JD, Clark LP, Phelps HR. Titanium investment casting defects: a metallographic overview. JOM. 2006;58(6):13.

Zhang HR, Tang XX, Zhou CG, Zhang SW. Comparison of directional solidification of gamma-tial alloys in conventional Al2O3 and novel Y2O3-coated Al2O3 crucibles. J Eur Ceram Soc. 2013;33(5):932.

Kostov A, Friedrich B. Predicting thermodynamic stability of crucible oxides in molten titanium and titanium alloys. Comput Mater Sci. 2006;38(2):374.

Cui RJ, Gao M, Zhang H, Gong SK. Interactions between TiAl alloys and yttria refractory material in casting process. J Mater Process Technol. 2010;210(9):1195.

Jerry CL, Anthony JF, Eoin JB. Inert calcia facecoats for investment casting of titanium and titanium–aluminide alloys. US Patent; 5766329.1998.

Kim MG, Kim SK, Kim YJ. Effect of mold material and binder on metal–mold interfacial reaction for investment casting of titanium alloys. Mater Trans. 2002;43(4):745.

Cheng X, Sun XD, Yuan C, Green NR, Withey PA. An Investigation of a TiAlO based refractory slurry face coat system for the investment casting of Ti–Al alloys. Intermetallics. 2012;29:61.

Liu HB, Shen B, Zhu M, Zhou X, Mao XM. Reaction between Ti and boron nitride based investment shell molds used for casting titanium alloys. Rare Met. 2008;27(6):617.

Lin K, Lin C. Interfacial reactions between zirconia and titanium. Scr Mater. 1998;39(10):1333.

Holcombe CE, Serandos TR. Consideration of yttria for vacuum induction melting of titanium. Metall Trans B Process Metall. 1983;14(3):497.

Gao M, Cui RJ, Ma LM, Zhang HR, Tang XX, Zhang H. Physical erosion of yttria crucibles in Ti–54Al alloy casting process. J Mater Process Technol. 2011;211(12):2004.

Lapin J, Gabalcova Z, Pelachova T. Effect of Y2O3 crucible on contamination of directionally solidified intermetallic Ti–46Al–8Nb alloy. Intermetallics. 2011;19(3):401.

Barbosa J, Ribeiro CS, Monteiro AC. influence of superheating on casting of gamma-TiAl. Intermetallics. 2007;15(7):954.

Lapin J, Ondrus L, Nazmy M. Directional solidification of intermetallic Ti–46Al–2W–0.5Si alloy in alumina moulds. Intermetallics. 2002;10(10):1029.

Cui RJ, Zhang HR, Tang XX. Interactions between Γ-Tial melt and Y2O3 ceramic material during directional solidification process. Trans Nonferrous Met Soc China. 2011;11:2415.

Liu GZ, Su YQ, Guo JJ, Ding HS, Jia J, Fu HZ. Evaporation tendency of components in Ti–6Al–4V alloy melt. Mater Sci Technol. 2001;02:175.

Wei YM, Lu ZG, Wu GP, Long XQ. Reaction between Ti–6Al–4V and Y2O3–SiO2 based face shell for investment casting. Rare Met. 2016;35(12):901.

Xie CM, Mo W, Li SQ. Titanium Near Net Forming Technology. Beijing: Metallurgical Industry Press; 2009. 11.

Peng WW, Zeng WD, Zhang XW, Shi CL. Relationship between color of oxidation layer and mechanical properties of TC18 titanium alloy. Rare Metal Mater Eng. 2013;42(2):360.

Liu WK, Cao XH, Peng SM, Long XG, Li HF, Yang MN, Zhang XH, Yan DY, Wang WD, Yang BF. The study on oxide layer on the surface of the titanium film in the oxygen. Mater Rev. 2004;18(5):94.

Kumar S, Narayanan TSNS, Raman SGS, Seshadri SK. Thermal oxidation of Ti6Al4V alloy: microstructural and electrochemical characterization. Mater Chem Phys. 2010;119(1–2):345.

Zhang WF, Gao W, Liu GY, Zhao AG, Tao CH. The influence of high temperature exposure on fracture behaviors of TC11 titanium alloy. J Aeronaut Mater. 2004;24(2):4.

Leyens C, Peters M. Titanium and Titanium Alloys. Chen ZH, transl. Beijing: Chemical Industry Press, 2005.175.

CamPbell J. Casting (Second edition). Li DZ, Li YY, transl. Beijing: Science Press, 2011.18.

Guo JJ, Su YQ. Thermodynamics and dynamics analysis on the melting process of titanium alloys with ISM. Harbin: Harbin institute of Technology Publisher; 1998. 90.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 50875144).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, X., Wei, YM. & Lu, ZG. Reaction of titanium investment castings made by Zr(CH3COO)2-Y2O3 shell. Rare Met. 36, 465–471 (2017). https://doi.org/10.1007/s12598-017-0920-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0920-y