Abstract

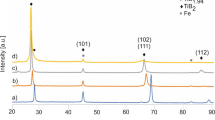

The approximately equimolar ratio AlCrNiSiTi multi-principal element alloy (MPEA) coatings were fabricated by laser cladding on Ti–6Al–4V (Ti64) alloy. Scanning electron microscopy (SEM), equipped with an energy-dispersive spectroscopy (EDS), and X-ray diffraction (XRD) were used to characterize the microstructure and composition. Investigations show that the coatings consist of (Ti, Cr)5Si3 and NiAl phases, formed by in situ reaction. The phase composition is initially explicated according to obtainable binary and ternary phase diagrams, and the formation Gibbs energy of Ti5Si3, V5Si3 and Cr5Si3. Dry sliding reciprocating friction and wear tests of the AlCrNiSiTi coating and Ti64 alloy substrate without coating were evaluated. A surface mapping profiler was used to evaluate the wear volume. The worn surface was characterized by SEM–EDS. The hardness and wear resistance of the AlCrNiSiTi coating are well compared with that of the basal material (Ti64). The main wear mechanism of the AlCrNiSiTi coating is slightly adhesive transfer from GCr15 counterpart, and a mixed layer composed of transferred materials and oxide is formed.

Similar content being viewed by others

Referencs

Huang C, Zhang Y, Vilar R. Microstructure and anti-oxidation behavior of laser clad Ni–20Cr coating on molybdenum surface. Surf Coat Technol. 2010;205(3):835.

Sun Q, Hu T, Fan H, Zhang Y, Hu L. Dry sliding wear behavior of TC11 alloy at 500 °C: influence of laser surface texturing. Tribol Int. 2015;92:136.

Zaddach AJ, Niu C, Oni AA, Fan M, Lebeau JM, Irving DL, Koch CC. Structure and magnetic properties of a multi-principal element Ni–Fe–Cr–Co–Zn–Mn alloy. Intermetallics. 2016;68:107.

Miracle D, Majumdar B, Wertz K, Gorsse S. New strategies and tests to accelerate discovery and development of multi-principal element structural alloys. Scr Mater. 2017;127:195.

Ren B, Zhao R, Liu Z, Guan S, Zhang H. Microstructure and properties of Al0.3CrFe1.5MnNi0.5Ti x and Al0.3CrFe1.5MnNi0.5Si x high-entropy alloys. Rare Met. 2014;33(2):149.

Wang FJ, Zhang Y. Effect of Co addition on crystal structure and mechanical properties of Ti0.5CrFeNiAlCo high entropy alloy. Mater Sci Eng, A. 2008;496(1):214.

Tung CC, Yeh JW, Shun TT, Chen SK, Huang YS, Chen HC. On the elemental effect of AlCoCrCuFeNi high-entropy alloy system. Mater Lett. 2007;61(1):1.

Otto F, Yang Y, Bei H, George EP. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013;61(7):2628.

Liu H, Zhang X, Jiang Y, Zhou R. Microstructure and high temperature oxidation resistance of in situ synthesized TiN/Ti3Al intermetallic composite coatings on Ti6Al4V alloy by laser cladding process. J Alloy Compd. 2016;670:268.

Zhang QY, Zhou Y, Liu JQ, Chen KM, Mo JG, Cui XH, Wang SQ. Wear behavior and mechanism of Fe-Al intermetallic coating prepared by hot-dip aluminizing and diffusion. Metall Mater Trans A. 2016;47(5):2232.

Guo L, Li M, Zhang Y, Ye F. Improved toughness and thermal expansion of non-stoichiometry Gd2−x Zr2 + xO7 + x/2 ceramics for thermal barrier coating application. J Mater Sci Technol. 2015;32(1):28.

Liu CT, Horton JA. Effect of refractory alloying additions on mechanical properties of near-stoichiometric NiAl. Mater Sci Eng, A. 1995;192–193(94):170.

Wang C, Guo L, Zhang Y, Zhao X, Ye F. Enhanced thermal expansion and fracture toughness of Sc2O3-doped Gd2Zr2O7 ceramics. Ceram Int. 2015;41(9):10730.

Murty BS, Yeh JW, Ranganathan S. High-Entropy Alloys. Boston: Elsevier Inc.; 2014. 13.

Huang C, Zhang Y, Rui V, Shen J. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V substrate. Mater Des. 2012;41:338.

Huang C, Zhang Y, Shen J, Rui V. Thermal stability and oxidation resistance of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V alloy. Surf Coat Technol. 2011;206(6):1389.

Sun DJ, Liang CY, Shang JL, Lai CW, Yin JH, Song YR, Zhang XH. Effect of Y2O3 content on high temperature oxidation resistance of Ni-20Cr-5Al alloy. Mater Mech Eng. 2016;40(4):34.

Matthews S, Schweizer M. High-temperature oxidation and smelt deposit corrosion of Ni-Cr-Ti arc-sprayed coatings. J Therm Spray Technol. 2013;22(6):932.

Leyens C, Fritscher K, Peters M, Kaysser WA. Transformation and oxidation of a sputtered low-expansion Ni–Cr–Al–Ti–Si bond coating for thermal barrier systems. Surf Coat Technol. 1997;94–95(97):155.

Du Y, Schuster JC. Experimental investigation and thermodynamic description of the Cr–Si–Ti system. Scand J Metall. 2002;31(1):25.

Du Y, Clavaguera N. Thermodynamic assessment of the Al–Ni system. J Alloy Compd. 1996;237(1–2):20.

Barin I. Thermochemical Data of Pure Substances. 3rd ed. Weinheim: Wiley-VCH Verlag GmbH; 1995. 1587.

Feuerbacher M. Dislocations and deformation microstructure in a B2-ordered Al28Co20Cr11Fe15Ni26 high-entropy alloy. Sci Rep. 2016;6:29700.

Choudhuri D, Gwalani B, Gorsse S, Mikler CV, Ramanujan RV, Gibson MA, Banerjee R. Change in the primary solidification phase from fcc to bcc-based B2 in high entropy or complex concentrated alloys. Scr Mater. 2016;127:186.

Huhn WP, Widom M. Prediction of A2 to B2 phase transition in the high-entropy alloy Mo–Nb–Ta–W. JOM. 2013;65(12):1772.

Tang Z, Gao MC, Diao H, Yang T, Liu J, Zuo T, Zhang Y, Lu Z, Cheng Y, Zhang Y. Aluminum alloying effects on lattice types, microstructures, and mechanical behavior of high-entropy alloys systems. JOM. 2013;65(12):1848.

Wang YP, Li BS, Fu HZ. Solid solution or intermetallics in a high-entropy alloy. Adv Eng Mater. 2009;11(8):641.

Bayer RG. Mechanical Wear Fundamentals and Testing, Revised and Expanded. New York: CRC Press; 2004. 22.

Wang L, Jiang W, Qin C, Chen L. Effect of starting SiC particle size on in situ fabrication of Ti5Si3/TiC composites. Mater Sci Eng A. 2006;425(1–2):219.

Li J, Gong H, Shi R, Yin Y. Rising crack-growth-resistance behavior of Al2O3 based composites toughened with Fe3Al intermetallic. Ceram Int. 2007;33(5):811.

Acknowledgements

This study was financially supported by the Chongqing Research Program of Basic Research and Frontier Technology (No. CSTC2013jcyjA50016), the National Natural Science Foundation of China (Nos. 51401039, 51571037 and 51204110) and the Scientific and Technological Research Program of Chongqing Municipal Education Commission (No. KJ1709204).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, C., Tang, YZ., Zhang, YZ. et al. Microstructure and dry sliding wear behavior of laser clad AlCrNiSiTi multi-principal element alloy coatings. Rare Met. 36, 562–568 (2017). https://doi.org/10.1007/s12598-017-0912-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0912-y