Abstract

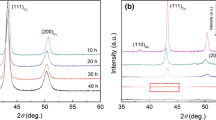

The ball milling process and the CuWO4–WO3 precursors were investigated, and a new highly concentrated wet ball-milled process (HWM) was designed. W–20 wt% Cu composite powders with excellent sintering property were synthesized by highly concentrated wet ball-milled process and co-reduction. The powders were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD), field electron transmission electron microscopy (FESEM) and laser-diffraction diameter tester. The results indicate that particle size of WO3–CuO powder mixtures decreases to 390 nm rapidly with the milling time increasing to 5 h. The CuWO4 precursors promote the microstructural homogeneity of W and Cu. W–Cu composite powders have a highly dispersed and well sintering property. The particle size of W–Cu powders milled by HWM for 5 h is about 680 nm. High-resolution transmission electron microscopy (HRTEM) result suggests that W phase and Cu phase are mixed at nanometer scale. The above W–Cu composite powders reach the relative density of about 99.3%.

Similar content being viewed by others

References

Zhou Y, Sun QX, Liu R, Wang XP, Liu CS, Fang QF. Microstructure and properties of fine grained W–15 wt% Cu composite sintered by microwave from the sol-gel prepared powders. J Alloys Compd. 2013;547(2):18.

Guo HP, Chen WG, Zhang H. Characterization of W80Cu20 alloy sheet prepared by hot-rolling. Rare Met. 2013;32(6):569.

Ryu SS, Park HR, Kim HK, Kim YD. On sinterability of Cu-coated W nanocomposite powder prepared by a hydrogen reduction of a high-energy ball-milled WO3–CuO mixture. J Mater Sci. 2012;47(20):7099.

Hong SH, Kim BK. Fabrication of W–20 wt% Cu composite nanopowder and sintered alloy with high thermal conductivity. Mater Lett. 2003;57(18):2761.

Ibrahim H, Aziz A, Rahma A. Enhanced liquid-phase sintering of W–Cu composites by liquid infiltration. Int J Refract Met Hard Mater. 2014;43(3):222.

Alam SN. Synthesis and characterization of W–Cu nanocomposites developed by mechanical alloying. Mater Sci Eng A. 2006;433(1):161.

Abbaszadeha H, Masoudib A, Safabinesha H, Takestani M. Investigation on the characteristics of micro- and nano-structured W–15 wt% Cu composites prepared by powder metallurgy route. Int J Refract Met Hard Mater. 2012;30(1):145.

Li BH, Kang ZY, Chen WG, Ding BJ. Preparation of nanosized W/Cu composite powder by sol-gel technique. Rare Met. 2005;24(2):170.

Venugopal T, Rao KP, Murty BS. Synthesis of Cu–W nanocomposite by high-energy ball milling. J Nanosci Nanotechnol. 2007;7(7):2376.

Lee GG, Ha GH, Kim BK. Synthesis of high density ultrafine W/Cu by mechano-thermochemical process. Int J Powder Metall. 2000;43(1):79.

Luo LM, Tan XY, Lu ZL, Zhu XY, Zan X, Luo GN, Wu YC. Sintering behavior of W-30Cu composite powder prepared by electroless plating. Int J Refract Met Hard Mater. 2014;42(1):51.

Sahoo PK, Kamal SSK, Premkumar M, Sreedhar B, Srivastava SK, Durai L. Synthesis, characterization and densification of W–Cu nanocomposite powders. Int J Refract Met Hard Mater. 2011;29(4):547.

Kim DG, Oh ST, Jeon H, Lee Ch, Kim Yd. Hydrogen-reduction behavior and microstructural characteristics of WO3–CuO powder mixtures with various milling time. J Alloys Compd. 2003;354(1–2):239.

Ryu SS, Kim YD, Moon IH. Dilatometric analysis on the sintering behavior of nanocrystalline W–Cu prepared by mechanical alloying. J Alloys Compd. 2002;335(1):233.

Sommer M, Stenger F, Peukert W, Wager NJ. Agglomeration and breakage of nanoparticles in stirred media mills—a comparison of different methods and models. Chem Eng Sci. 2006;26(1):135.

Kim DG, Mi KH, Chang SY, Oh ST, Lee CH, Kim YD. Effect of pre-reduced Cu particles on hydrogen-reduction of W-oxide in WO3–CuO powder mixtures. Mater Sci Eng A. 2005;399(1):326.

Ahmadi E, Malekzadeh M, Sadrnezhaad SK. W–15 wt% Cu nano-composite produced by hydrogen-reduction/sintering of WO3–CuO nano-powder. Int J Refract Met Hard Mater. 2010;28(3):441.

Suryanarayana C. Mechanical alloying and milling. Prog Mater Sci. 2001;46(1):1.

Li YP, Qu XH, Zheng ZS, Lei CM, Zou ZQ, Yu S. Properties of W–Cu composite powder produced by a thermo-mechanical method. Int J Refract Met Hard Mater. 2003;21(5):259.

Li JQ, Chen WG, Tao WJ, Shao F, Ding BJ. Nano-composite powder of tungsten coated copper produced by thermo-chemistry co-reduction. Rare Metal Mat Eng. 2012;41(12):2091.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51274246).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, BH., Fu, Z., Qi, CK. et al. Preparation of highly dispersed superfine W–20 wt% Cu composite powder with excellent sintering property by highly concentrated wet ball-milled process. Rare Met. 37, 961–967 (2018). https://doi.org/10.1007/s12598-016-0841-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0841-1