Abstract

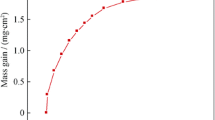

In this paper, the isothermal oxidation kinetics and oxidation behavior of GH586 superalloy from 800 to 1000 °C were investigated. The oxide scale morphologies of the surfaces and the cross sections after oxidation were characterized by means of X-ray diffraction (XRD) and scanning electron microscope (SEM) equipped with energy-dispersive spectroscopy (EDS). The results show that the growth of the oxide scales on the surface of superalloy GH586 obeys a parabolic law with the activation energy of 241.4 kJ·mol−1 from 800 to 1000 °C. The dense oxide scale formed at 800 °C is mainly composed of Cr2O3, NiCr2O4 and a small amount of TiO2. At 900 °C, the oxide scale is divided into two layers: the outer layer with multiple cracks is mainly composed of Cr2O3 and TiO2, while the inner is a layer of dense Cr2O3. Under the oxide scale, aluminum-rich oxides along the grain boundaries are generated by the internal oxidation. At 1000 °C for 100 h, cracks throughout the whole oxide film accelerate the oxidation rate of Ni-based superalloy GH586 and large blocks of TiO2 in the oxide scale are generated, resulting in the spallation of oxide scale.

Similar content being viewed by others

References

Wang J, Zhou LZ, Sheng LY. The microstructure evolution and its effect on the mechanical properties of a hot-corrosion resistant Ni-based superalloy during long-term thermal exposure. Mater Des. 2012;39(39):55.

Yuan SH, Wang YR, Wei DS. Experimental investigation on low cycle fatigue and fracture behavior of a notched Ni-based superalloy at elevated temperature. Fatigue Fract Eng Mater Struct. 2014;37(9):1002.

Liua CT, Mab J, Sunc XF. Oxidation behavior of a single-crystal Ni-base superalloy between 900 and 1000 °C in air. J Alloys Compd. 2010;491(S1–2):522.

Ning LK, Zheng Z, An FQ, Tang S, Tong J. Thermal fatigue behavior of K125L superalloy. Rare Met. 2016;35(2):1–5.

Fei M. Researching on high-temperature oxidation property of NiCrAlY coatings on nickel-base superalloy K465. Harbin: Harbin Engineering University; 2012. 1.

Wu XC. Research on high-temperature oxidation property of calorized coating on GH907 superalloys. Harbin: Harbin Engineering University; 2011. 1.

Gao L. Research for high temperature oxidation properties of aluminized coating on K438 superalloy. Harbin: Harbin Engineering University; 2004. 1.

Shi CX. High Temperature Materials Branch of Chinese Society for Metals, China Superalloys Handbook. Beijing: China Standard Press; 2012. 818.

Hua YQ, Rong Z, Ye YX. Laser shock processing effects on isothermal oxidation resistance of GH586 superalloy. Appl Surf Sci. 2015;330(6):439.

Wu MY, Chen MH, Zhu SL, Wang FH. Effect of sand blasting on oxidation behavior of K38G superalloy at 1000C. Corros Sci. 2015;92:256.

Wang CJ, Chen SM. Microstructure and cyclic oxidation behavior of hot dip aluminized coating on Ni-base superalloy Inconel 718. Surf Coat Technol. 2006;201(7):6601.

Albert B, Völkl R, Glatzel U. High-temperature oxidation behavior of two nickel-based superalloys produced by metal injection molding for aero engine applications. Metall Mater Trans A. 2014;45A(10):4561.

Weng F, Yu HJ, Chen CZ, Wan K. High-temperature oxidation behavior of Ni-based superalloys with Nb and Y and the interface characteristics of oxidation scales. Surf Interface Anal. 2015;47(3):362.

Liu PS, Liang KM. High-temperature oxidation behavior of the Co-base superalloy DZ40 M in air. Oxid Met. 2000;53(3):351.

Yun DW, Seo SM, Jeong HW, Yoo YS. The cyclic oxidation behaviour of Ni-based superalloy GTD-111 with sulphur impurities at 1100 °C. Corros Sci. 2014;90:392–401.

Cruchley S, Taylor MP, Evans HE. Characterisation of subsurface oxidation damage in Ni based superalloy. Mater Sci Technol. 2014;30(15):1884.

Geng L, Na YS, Park NK. Oxidation behavior of alloy 718 at a high temperature. Mater Des. 2007;28(3):978.

Guo JT. Materials Science and Engineering for Superalloys (Vol. 1). Beijing: Sciences Press; 2008. 4.

Xu GH. Study on hot-working parameters and heat treatment of GH586 superalloy. Shenyang: Northeastern University; 2004. 40.

Zhu LJ, Zhu SL, Wang FH, Zhang JQ. Comparison of the cyclic oxidation behavior of low expansion Ni+Cr AlYSiN nanocomposite and a NiCrAlYSi coating. Corros Sci. 2014;80(3):393.

Wang MQ, Qu JL, Yin TZ, Sheng JY. Study on oxidation behavior of alloy GH4720Li at high temperatures. J Iron Steel Res. 2010;22(9):28.

Li Y. High-temperature oxidation, hot corrosion of five Ni-base superalloys and their protection. Shenyang: Northeastern University; 2004. 35.

Liang JC, Zhou WP, Zhang FG, Mu JG, Zhao HB. Evolution analysis of existing forms of Ti and Al elements during preparation of TiAlN coating. Chin J Rare Met. 2014;38(4):561.

Cao H, Peng CZ, Yang T, Xiang L, Xiong W. Microstructure and high temperature oxidation behavior of Cu30Ni10Cr8Al2Zr alloy. Chin J Rare Met. 2014;38(6):1121.

Birks N, Meier GH. Introduction to high temperature oxidation of metals. Beijing: High Education Press; 2010. 120.

Ren X, Wang FH, Wang X. High-temperature oxidation and hot corrosion behaviors of the NiCr+CrAl coating on a nickel-based superalloy. Surf Coat Technol. 2005;198(S1–3):425.

Yun DW, Seo SM, Jeong HW, Yoo YS. The effects of the minor alloying element Al, Si and Mn on the cyclic oxidation of Ni–Cr–W–Mo alloys. Corros Sci. 2014;83(3):176.

Zhang S, Wang Q, Zhao XS, Zhang CH. High temperature oxidation behavior of cast Ni-based superalloy K444. J Shenyang Univ Technol. 2010;32(2):136.

Wang L, Pan LL, Peng H, Guo HB, Gong SK. Cyclic oxidation behavior of Cr-/Si-modified NiAlHf coatings on single-crystal superalloy produced by EB-PVD. Rare Met. 2016;35(5):1–5.

Fang L, Liu XG, Li Y, Yuan C, Guo JT. Oxidation kinetics of cast Ni-base superalloy K44. J Shenyang Inst Chem Technol. 2004;18(2):121–4.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51641102), the Natural Science Foundation of Jiangsu Province (No. 16KJB430035), and the Nantong Science and Technology Project (No. GY12015032).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, JD., Zhang, JS., Hua, YQ. et al. High temperature oxidation behavior of Ni-based superalloy GH586 in air. Rare Met. 36, 878–885 (2017). https://doi.org/10.1007/s12598-016-0823-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0823-3