Abstract

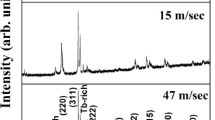

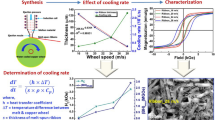

In this study, the effect of wheel speed and mischmetal (MM) content on the magnetic properties of MMFeB ribbons was investigated. The samples were prepared via direct solidification technique. The nominal composition of the alloy ingots is MM x Fe92−x B8 with x varying from 9 to 15 in steps of 2. Experimental results show the overall magnetic properties of the ribbons. Analysis of the results shows that the magnetic properties first improve and then degrade with the wheel speed and MM content increasing. Increase in MM content leads to better formation of crystal texture in the ribbons, indicating that the α-Fe phase might undermine the formation of crystal texture. Magnetic properties results show that the coercivity of the ribbons rises with an appropriate increase in both MM content and wheel speed during melt-spun process. The strongest magnetic properties of the ribbons (remanence of M r = 0.72 T, intrinsic coercivity of H cj = 352.58 kA·m−1, and maximum energy product of (BH)max = 72.14 kJ·m−3) are obtained for compositions where x = 13 and a wheel speed of v = 20 m·s−1.

Graphical Abstract

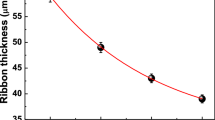

The variation in maximum remanence (M r), coercivity (H cj), and maximum energy product ((BH)max) values were analyzed as a function of wheel speed for the MM13Fe79B8 melt-spun ribbons. All of the ribbons’ magnetic properties (M r, H cj, and (BH)max) first increase as the wheel speed increases up to 20 m·s−1 and then decrease gradually. The best magnetic properties are obtained at a wheel speed of 20 m·s−1, achieving M r value of 0.72 T, H cj value of 352.58 kA·m−1, and (BH)max value of 72.14 kJ·m−3.

Similar content being viewed by others

References

Sagawa M, Fujimura S, Togawa N, Yamamoto H, Matsuura Y. New material for permanent magnets on a base of Nd and Fe. J Appl Phys. 1984;55(6):2083.

Yu LQ, Zhang J, Hu SQ, Han ZD, Yan M. Production for high thermal stability NdFeB magnets. Magn Magn Mater. 2008;320(8):1427.

Hu ZH, Zhu MG, Li W, Lian FZ. Effect of Nb on the coercivity and impact toughness of sintered Nd–Fe–B magnets. Magn Magn Mater. 2008;320(3/4):96.

Li WF, Ohkubo T, Hono K. Effect of post-sinter annealing on the coercivity and microstructure of Nd–Fe–B permanent magnets. Acta Mater. 2009;57(5):1337.

Tang J, Yang LR, Zhang L, Wei CF, Mei Y, Wen YG. Succession law of Nd–Fe–B alloys with different coercivities. Rare Met. 2015;34(9):657.

Zhou SZ, Dong QF. Super Permanent Magnets: Rare Earth Permanent Magnetic Material. Beijing: Metallurgical Industry Press; 2004. 282.

Niu E, Chen ZA, Chen GA, Zhao YG, Zhang J, Rao XL, Hu BP, Wang ZX. Achievement of high coercivity in sintered R–Fe–B magnets based on misch-metal by dual alloy method. J Appl Phys. 2014;115(113912):1.

Guan LB, Niu JJ, Hao SZ, Wang JZ, Ma JH, An LJ, Li QY. Technical study of RE–Fe–B magnet preparation using mixture rare earth. Mater China. 2009;28(3):51.

Song HD, Chen PL. Permanent Magnets Materials and Application. Beijing: Metallurgical Industry Press; 1984. 7.

Zhou SZ, Dong QF, Gao XX. Sintered NdFeB Rare Earth Permanent Magnet Materials and Technology. Beijing: Metallurgical Industry Press; 2011. 65.

Chang WC, Wu SH, Ma BM, Bounds CO. The effects of La-substitution on the microstructure and magnetic properties of nanocomposite NdFeB melt spun ribbons. Magn Magn Mater. 1997;167(96):65.

Qiu J, Li SD, Liu MM, Wu JP, Hu Y, Cai XL, Lin JH, Wang LL. Effect of wheel speed on the microstructure and magnetic properties of melt-spun (Nd0.75Dy0.25)10.5Zr2Fe82B5.5 ribbons. Adv Mater Res. 2012;569(1):23.

Wu SJ, Bao XQ, Xiang DL, Zhu J, Gao XX. Microstructure and magnetic properties of (Nd, Pr, Ce)–Fe–B magnets. J Univ Sci Technol Beijing. 2013;35(6):778.

Wang L, Chen JW, Yue M, Liu RM, Liu WQ, Zhang DT, Zhang JX, Zhang PY, Ge HL. Crystallographic alignment and magnetic anisotropy in melt-spun Nd–Fe–B/α-Fe composite ribbons with different neodymium contents. J Rare Earths. 2011;29(5):471.

Zhao GP, Ong CK, Feng YP, Lim SH, Ding J. Remanence enhancement of single-phased isotropic nanostructured permanent magnets. Magn Magn Mater. 1999;192(543/552):551.

Bao XQ, Guo XY, Guo JC, Gao XX. Effect of Ga addition on the magnetic properties and microstructure of nanocrystalline Nd12.3Fe81.7B6.0 ribbons. Rare Met. 2011;30(5):448.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Nos. 51461033, 51571126, 51541105, and 11547032), the Inner Mongolia Innovative Research Team (No. 3400102), the Inner Mongolia Science Foundation (No. 2013MS0110), the Provincial Major Science and Technology Project of Inner Mongolia (No. 2009J1006), the Baotou Major Research Project Special for Rare Earth (No. 2012R1006), and the Inner Mongolia University of Science and Technology Innovation Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, XF., Zhang, WK., Li, YF. et al. Magnetic properties of melt-spun MM–Fe–B ribbons with different wheel speeds and mischmetal contents. Rare Met. 36, 992–996 (2017). https://doi.org/10.1007/s12598-016-0745-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0745-0