Abstract

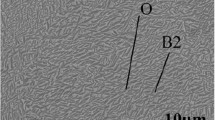

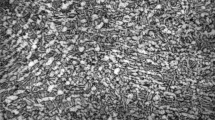

The isothermal hot compression tests of Ti–15Al–12Nb alloy under wide range of strain rates (0.01–10.00 s−1) and deformation temperatures (950, 1000, 1050, and 1100 °C) were carried out using Gleeble-3500 thermo-simulation machine. A constitutive equation represented as a function of temperature, strain rate and true strain was developed, and the hot deformation apparent activation energy is calculated to be about 453 kJ·mol−1. By employing dynamic material model (DMM), the processing maps of Ti–15Al–12Nb alloy at various strains were established. Maximum efficiency of about 57 % for power dissipation is obtained at high temperature and low strain rate. Owing to the high power dissipation efficiency and excellent processing ability in dynamic recrystallization (DRX) zone for metal material, the optimum processing conditions are selected as the temperature range of 1050–1100 °C and the strain rate range of 0.01–0.10 s−1. Using transmission electron microscopy (TEM) studies, it is found that the dislocation density is directly associated with the value of processing efficiency. It is observed that when the processing efficiency is about 22 %, the dislocation density is reasonably large. The flow instability region occurs at strain rate of 10.00 s−1 with cracks, which should be avoided during hot processing to obtain the required mechanical properties.

Similar content being viewed by others

References

Jia JB, Zhang KF, Liu LM, Wu FY. Hot deformation behavior and processing map of a powder metallurgy Ti–22Al–25Nb alloy. J Alloy Compd. 2014;600:215.

Wang Y, Liu Y, Yang GY, Li JB, Liu B, Wang JW, Li HZ. Hot deformation behaviors of β phase containing Ti–43Al–4Nb–1.4W-based alloy. Mater Sci Eng A. 2013;577:210.

Liu SF, Li MQ, Luo J, Yang Z. Deformation behavior in the isothermal compression of Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater Sci Eng, A. 2014;589:15.

Liu YH, Ning YQ, Yao ZK, Guo HZ. Hot deformation behavior of Ti–6.0Al–7.0Nb biomedical alloy by using processing map. J Alloy Compd. 2014;587:183.

Du ZH, Jiang SS, Zhang KF. The hot deformation behavior and processing map of Ti–47.5Al–Cr–V alloy. Mater Des. 2015;86:464.

Sun Y, Wan ZP, Hu LX, Ren JS. Characterization of hot processing parameters of powder metallurgy TiAl based alloy based on the activation energy map and processing map. Mater Des. 2015;86:922.

Bai XF, Zhao YQ, Zeng WD, Jia ZQ, Zhang YS. Characterization of hot deformation behavior of a biomedical titanium alloy TLM. Mater Sci Eng, A. 2014;598:236.

Sun Y, Zeng WD, Ma X, Xu B, Liang XB, Zhang JW. A hybrid approach for processing parameters optimization of Ti–22Al–25Nb alloy during hot deformation using artificial neural network and genetic algorithm. Intermetallics. 2011;19:1014.

Wang G, Xu L, Wang Y, Zheng Z, Cui YY, Yang R. Processing maps for hot working behavior of a PM TiAl alloy. J Mater Sci Technol. 2011;27(10):893.

Sun Y, Hu LX, Ren JS. Investigation on the hot deformation behavior of powder metallurgy TiAl-based alloy using 3D processing map. J Mater Charact. 2015;100:163.

Li HZ, Zeng M, Liang XP, Li Z, Liu Y. Flow behavior and processing map of PM Ti–47Al–2Cr–0.2Mo alloy. Trans Nonferrous Metals Soc China. 2012;22(4):754.

Li JB, Liu Y, Wang Y, Liu B, Lu B, Liang XP. Constitutive equation and processing map for hot compressed as-cast Ti–43Al–4Nb–1.4W–0.6B alloy. Trans Nonferrous Metals Soc China. 2013;23(11):3383.

Paradkar AG, Kamat SV, Gogia AK, Kashyap BP. On the validity of Hall–Petch equation for single-phase Ti–Al–Nb alloys undergoing stress-induced martensitic transformation. Mater Sci Eng, A. 2009;520:168.

Paradkar AG, Kamat SV, Gogia AK, Kashyap BP. Effect of Al and Nb on the trigger stress for stress-induced martensitic transformation during tensile loading in Ti–Al–Nb alloys. Mater Sci Eng, A. 2008;487:14.

Sun Y, Hu LX, Ren JS. Investigation on the hot deformation behavior of powder metallurgy TiAl-based alloy using 3D processing map. J Mater Character. 2015;100:163.

Zhao HZ, Xiao L, Geb P, Sun J, Xi ZP. Hot deformation behaviour and processing map of Ti-1300 alloy. Mater Sci Eng, A. 2014;604:111.

Tan YB, Duan JL, Yang LH, Liu WC, Zhang JW, Liu RP. Hot deformation behaviour of Ti–20Zr–6.5Al–4V alloy in the α + β and single β phase field. Mater Sci Eng, A. 2014;609:226.

Fan JK, Kou HC, Lai MJ, Tang B, Chang H, Li JS. Characterization of hot deformation behavior of a new near beta titanium alloy: Ti-7333. Mater Des. 2013;49:945.

Deng TQ, Ye L, Sun HF, Hu LX, Yan SJ. Development of flow stress model for hot deformation of Ti-47 % Al alloy. Trans Nonferrous Metals Soc China. 2011;21(S2):308.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bobbili, R., Madhu, V. Hot deformation behavior and processing maps of Ti–15Al–12Nb alloy. Rare Met. 41, 2316–2323 (2022). https://doi.org/10.1007/s12598-016-0699-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0699-2