Abstract

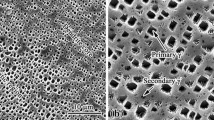

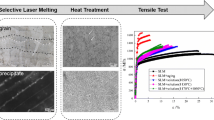

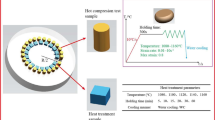

The morphological evolution of γ′ precipitates for a damaged nickel-based superalloy GTD-111 under different rejuvenation heat treatments (RHTs) was investigated. The degenerated γ′ precipitates can be completely dissolved into the γ matrix under the full solution condition of 1200 °C/2 h, and only fine γ′ precipitates re-precipitated during the cooling stage of the full solution can be observed, but these fine γ′ precipitates cannot grow continuously to be similar as those in virgin alloy during the subsequent long-term aging. It is found that the newly developed RHT schedule, including the full solution, the partial solution, and the aging treatments, can effectively recover the degenerated γ′ precipitates in the GTD-111 superalloy to their original state. Moreover, the effects of different RHT cycles on the γ′ evolution were investigated. The experimental results show that the degenerated γ′ precipitates can be restored to be analogous with those in virgin alloy by slow cooling after the full solution and an appropriate partial solution followed by the long-term aging. Compared with the different microhardness under various RHT schedules, the microhardness after full solution and partial solution followed by aging is more close to that of the initial alloy.

Similar content being viewed by others

References

Reed RC. The Superalloys: Fundamentals and Applications. Cambridge: Cambridge University Press; 2006. 90.

Huda Z, Edi P. Materials selection in design of structures and engines of supersonic aircrafts: a review. Mater Des. 2013;46:552.

Koul A, Castillo R. Assessment of service induced microstructural damage and its rejuvenation in turbine blades. Metall Mater Trans A. 1988;19(8):2049.

Ejaz N, Mansoor M, Salam I. Effect of high temperature exposure on the microstructure of Udimet-500 super alloy. J Mater Sci. 2010;45(16):4507.

Baldan A. Rejuvenation procedures to recover creep properties of nickel-base superalloys by heat treatment and hot isostatic pressing techniques. J Mater Sci. 1991;26(13):3409.

Stevens RA, Flewitt PEJ. The effects of γ′ precipitate coarsening during isothermal aging and creep of the nickel-base superalloy IN-738. Mater Sci Eng. 1979;37(3):237.

Yang JX, Zheng Q, Sun XF, Guan HR, Hu ZQ. The microstructure evolution and its effect on the mechanical properties of a hot-corrosion resistant Ni-based superalloy during long-term thermal exposure. Mater Des. 2012;39:55.

Tian SG, Su Y, Qian BJ, Yu XF, Liang FS, Li AA. Creep behavior of a single crystal nickel-based superalloy containing 4.2% Re. Mater Des. 2012;37:236.

Tawancy HM, Al-Hdhrami L. Failure of refurbished turbine blades in a power station by improper heat treatment. Eng Fail Anal. 2009;16(3):810.

Lvova E. A comparison of aging kinetics of new and rejuvenated conventionally cast GTD-111 gas turbine blades. J Mater Eng Perform. 2007;16(2):254.

Wangyao P, Krongtong V, Panich N, Chuankrerkkul N, Lothongkum G. Effect of 12 heat treatment conditions after HIP process on microstructural refurbishment in cast nickel-based superalloy, GTD-111. High Temp Mater Process. 2007;26(2):151.

Wangyao P, Lothongkum G, Krongtong V, Pailai S, Polsilapa S. Effect of heat treatments after HIP process on microstructure refurbishment in cast nickel base superalloy, IN-738. J Met Mater Mine. 2005;15(2):69.

Hosseini SS, Nategh S, Ekrami AA. Microstructural evolution in damaged IN738LC alloy during various steps of rejuvenation heat treatments. J Alloys Compd. 2012;512(1):340.

Kim MT, Chang SY, Won JB. Effect of HIP process on the micro-structural evolution of a nickel-based superalloy. Mater Sci Eng A. 2006;441(1):126.

Hosseini SS, Nategh S, Ekrami AA. Changes of γ’ precipitate characteristics in damaged superalloy IN738LC during different stages of rejuvenation heat treatment cycles. Mater Sci Technol. 2012;28(2):213.

Krongtong V, Tuengsook P, Homkrajai W, Nisaratanaporn E, Wangyao P. The effect of re-heat treatments on microstructural restoration in cast nickel superalloy turbine blade, GTD-111. Acta Metall Slovaca. 2005;11(2):171.

Wangyao P, Krongtong V, Homkrajai W, Panich N, Lothongkum G. OM study of effect of HIP and heat treatments on microstructural restoration in cast nickel-based superalloy, GTD-111. J Met Mater Miner. 2007;17(1):87.

Lvova E, Norsworthy D. Influence of service-induced microstructural changes on the aging kinetics of rejuvenated Ni-based superalloy gas turbine blades. J Mater Eng Perform. 2001;10(3):299.

Li H, Song X, Wang Y, Chen G. Characterization of γ′ precipitates in a nickel base superalloy quenching from aging temperature at different rates. Rare Met. 2010;29(2):204.

Sajjadi SA, Zebarjad SM, Guthrie RIL, Isac M. Microstructure evolution of high-performance Ni-base superalloy GTD-111 with heat treatment parameters. J Mater Process Technol. 2006;175(1):376.

Dwarapureddy AK, Balikci E, Ibekwe S, Raman A. Activation energy for growth in single size distribution and the dissolution features of γ′ precipitates in the superalloy IN738LC. J Mater Sci. 2008;43(6):1802.

Roy I, Balikci E, Ibekwe S, Raman A. Precipitate growth activation energy requirements in the duplex size γ′ distribution in the superalloy IN738LC. J Mater Sci. 2005;40(23):6207.

Grosdidier T, Hazotte A, Simon A. Precipitation and dissolution processes in γ/γ′ single crystal nickel-based superalloys. Mater Sci Eng A. 1998;256(1):183.

Acknowledgments

This study was financially supported by the University-Industry Cooperation Project from Aviation Industry Corporation of China (No. cxy2010BH06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, XM., Zhou, Y., Wang, TY. et al. Morphological evolution of γ′ precipitate under various rejuvenation heat treatment cycles in a damaged nickel-based superalloy. Rare Met. 42, 645–650 (2023). https://doi.org/10.1007/s12598-015-0687-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0687-y