Abstract

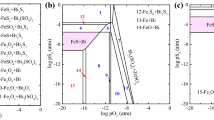

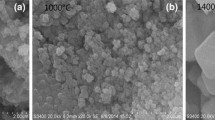

Sc2O3 was successfully extracted and separated from Bayan Obo tailings by a CaCl2-reductive carbon powder-combinative roasting method. The optimum process condition was obtained through adjusting specific effect factors. It is found that Sc2O3 with the ratio of 87.51 % is leached out under roasting temperature of 800 °C for 2 h through adding 73 % CaCl2, and 20 % reductive carbon powder with liquid to solid ratio of 3. Moreover, the specific reaction mechanism during roasting process was investigated by thermogravimetric–differential scanning calorimetry (TG-DSC) and X-ray diffraction (XRD) techniques. The results show that the main phases (SiO2, CaF2 and NaFeSi2O6) as well as important phases (LiScSi2O6, REFCO3 and REPO4) would turn into new phases (CaFeSiO4, Fe, Ca3(PO4)2, NaCl, RE2O3 and Sc2O3) after complicated reactions, which effectively break up the original mineral compositions and activate the existing state of containing scandium matter, consequently facilitating the subsequent hydrochloric acid leaching process.

Similar content being viewed by others

References

Maestro P, Huguenin D. Industrial applications of rare earths: which way for the end of the century. J Alloys Compd. 1995;225(1–2):520.

Yin SH, Wu WY, Bian X, Luo Y, Zhang FY. Solvent extraction of La(III) from chloride medium in the presence of two water soluble complex agents with di-(2-ethylhexyl) phosphoric acid. Ind Eng Chem Res. 2013;52(25):8558.

Zhang TW, Zhu CJ, Zheng C, Li J. Preparation and characterization of Cd1−xZnxS buffer layers for thin film solar cells. Rare Met. 2014;32(1):47.

Wu DG, Yan SH, Li ZG, Wang ZQ, Wang XS. Effect of samarium on corrosion behavior of as-cast AZ92 magnesium alloy. Chin J Rare Met. 2013;37(2):199.

Wu J, Li W, Tang BY, Peng LM, Ding WJ. Generalized planner fault energies, twinning and ductility of L12 type Al3Sc and Al3Mg. Solid State Sci. 2011;13(1):120.

Lei Z, Zhu QS. Low temperature processing of dense nanocrystalline scandia-doped zirconia (ScSZ) ceramics. Solid State Ion. 2005;176(37–38):2791.

Shi CY, Hao YM, Tan YQ, Song R. The magnetic properties of Bi0.9Ba0.1Fe0.81M0.09Ti0.1O3 solid solutions (M-Co, Mn, Sc, Al). Mater Res Bull. 2011;46(11):1848.

Tokurakawa M, Shirakawa A, Ueda K, Yanagitani T. Diod-pumped ultrashort-pulse generation based on Yb3+:Sc2O3 and Yb3+:Sc2O3 ceramic multi-gain-media oscillator. Opt Soc Am. 2009;17(5):3353.

Wang LS, Long ZQ, Huang XW, Yu Y. Recovery or rare earths from wet-process phosphoric acid. Hydrometallurgy. 2010;101(1–2):41.

Wang LS, Yu Y, Huang XW, Long ZQ. Toward green comprehensive utilization of bastnaesite: simultaneous recovery of cerium, fluorine, and thorium from bastnaesite leach liquor using HEH(EHP). Chem Eng J. 2013;215–216:162.

Xu GX. Rare Earths. 2nd ed. Beijing: Metallurgy Industry Press; 1995. 364.

Bautista RG, Wong MM. Rare Earths Extraction Preparation and Applications. Warrendale: TMS; 1989. 15.

Xu YH, Liu HJ, Meng ZJ, Cui JG. Decomposition of bastnasite and monazite mixed rare earth minerals calcined by alkali liquid. J Rare Earths. 2012;30(2):155.

Wu WY, Hu GY, Sun SC, Chen XD. Decomposition reaction of mixed rare earth concentrate and roasted with CaO and NaCl. J Rare Earths. 2004;22(1):53.

Shi WZ, Zhu GC, Hua J, Chi RA. Recovery of RE from Baotou rare earth concentrate with chlorination roasting. Trans Nonferrous Met Soc China. 2003;13(2):438.

Wu WY, Bian X, Sun SC, Tu GF. Study on roasting decomposition of mixed rare earth concentrate in CaO-NaCl-CaCl2. J Rare Earths. 2006;24(1):23.

Sun YH, Wang ZC, Guo L. Mutual separation characteristics of neighboring rare earth elements Nd, Sm, Eu and Gd using stepwise chlorination-chemical vapor transport. J Alloy Compd. 1998;269(1):88.

Wang ZC, Yu J, Yu YL. Comparative study of the mutual separation characteristics and mechanism for neighboring rare earth elements from binary chloride mixtures and oxide mixtures via vapor complexes. Bull Chem Soc Jpn. 1996;69(8):2369.

Xing PF, Li F, Guo J, Tu GF. High temperature de-phosphorus behavior of Baotou mixed rare earth concentrate with carbon. J Rare Earths. 2010;28(S1):194.

Abouzeid AZM. Physical and thermal treatment of phosphate ores—an overview. Int J Miner Process. 2008;85(4):59.

Wang QC. Study on some rare elements extraction of Banyan Obo tailings. Shenyang: Northeastern University; 2008. 21.

Dong DQ. Roast-chloridization joint decomposition of Banyan Obo tailings. Shenyang: Northeastern University; 2008. 22.

Zeng FW. Gravity concentration and carbochlorination for BaoSteel’s concentrator tailings. Shenyang: Northeastern University; 2005. 9.

Kan HM. Study on carbo-chlorination for rare earth gangue. Shenyang: Northeastern University; 2004. 4.

Acknowledgments

This study was financially supported by the National High Technology Research and Development Program (No. 2013AA031002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bao, XJ., Wang, ZJ., Xi, LJ. et al. Separation of Sc2O3 from Bayan Obo tailings through an innovative roasting method. Rare Met. 41, 1071–1076 (2022). https://doi.org/10.1007/s12598-015-0511-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0511-8