Abstract

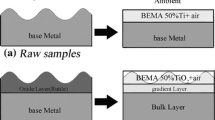

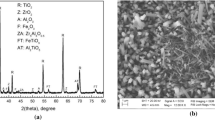

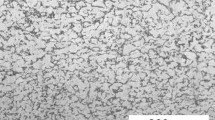

In this study, the effect of thermal oxidation on the lattice parameters of Ti–4Al–2V alloy was studied. Samples were oxidized at 450, 600 and 650 °C for 1–7 h in electric furnace under air atmosphere. The lattice parameters were determined using the Cohen method as a function of oxidation time at each temperature. The lattice parameters of as-received alloy are calculated as a = 0.29289 nm and c = 0.46652 nm. The thermal oxidation at 450 °C results in a gradual increase in a-parameter, whereas it goes through a maximum at higher temperatures (600 and 700 °C). The results show that these maximums are reduced to an approximately constant value after a long-time oxidation. The c-parameter generally increases over the whole treatment condition. It is believed that these variations could be due to the dissolution of oxygen atoms in octahedral sites of hcp lattice of titanium.

Similar content being viewed by others

References

Boyer RR. Attributes, characteristics, and applications of titanium and its alloys. JOM. 2010;62(5):21.

Li C, Zhu M, Wang N, Lu X, Cheng S. Application of titanium alloy in airplane. Chin J Rare Met. 2009;33(1):84.

Hurless BE, Froes FHS. Cutting the cost of titanium. Adv Mater Process USA. 2002;160(12):37.

da Silva LM, Claro APRA, Donato TAG, Arana-Chavez VE, Moraes JCS, Buzalaf MAR, Grandini CR. Influence of heat treatment and oxygen doping on the mechanical properties and biocompatibility of titanium-niobium binary alloys. Artif Organs. 2011;35(5):516.

Tahashi K, Sato E. Mechanical properties of Ti–6Al–4V alloy using off grade sponge titanium as raw material. J Iron Steel Inst Jpn. 2012;98(9):491–6.

Kumar A, Gupta MC. Surface preparation of Ti–3Al–2.5V alloy tubes for welding using a fiber laser. Opt Lasers Eng. 2009;47(11):1259.

Liu J, Zhang S, Wang H. Microstructure and wear resistance of C-W elements laser surface alloyed coating of TA15 titanium alloy. Heat Treat Met. 2012;37(3):37.

Madhusudhan Reddy G, Satya Prasad K, Rao KS, Mohandas T. Friction surfacing of titanium alloy with aluminium metal matrix composite. Surf Eng. 2011;27(2):92.

Michiyama Y, Demizu K. Surface age hardening and wear properties of beta-type titanium alloy by laser surface solution treatment. J Jpn Inst Met. 2012;76(7):456.

Nishimoto A, Bell TE, Bell T. Feasibility study of active screen plasma nitriding of titanium alloy. Surf Eng. 2010;26(1–2):74.

Sylvestre M, Zaidi H, Rivière JP, Eyidi D, Doyen F. Fretting contact study of Ti–6Al–4V/graphite couples in a dry shaft/bearing contact with thrust: influence of plasma nitriding of the titanium alloy. Surf Coat Technol. 2010;205(5):1374.

Gulbransen EA, Andrew KF. Kinetics of the reaction of titanium, columbium with O2, N2 and H2. Met Trans. 1949;185:741.

Rautray TR, Narayanan R, Kwon TY, Kim KH. Surface modification of titanium and titanium alloys by ion implantation. J Biomed Mater Res Part B Appl Biomater. 2010;93(2):581.

Jamesh M, Kumar S, Sankara Narayanan TSN. Effect of thermal oxidation on corrosion resistance of commercially pure titanium in acid medium. J Mater Eng Perform. 2012;21(6):900.

Pichuhin AT, Yas’kiv OI, Luk’yanenko OH, Pohrelyuk IM. Influence of the phase-structural state of the surface layers on the mechanical properties of VT1-0 titanium alloy. Mater Sci. 2012;47(5):1.

De Nardo L, Raffaini G, Ebramzadeh E, Ganazzoli F. Titanium oxide modeling and design for innovative biomedical surfaces: a concise review. Int J Artif Organs. 2012;35(9):629.

Omidbakhsh F, Ebrahimi AR, Mousavi SH, Khosroshahi RA, Nazarpour S. Effect of oxygen boost diffusion treatment on fatigue behavior of Ti–4Al–2V alloy. Surf Coat Technol. 2011;205(8–9):2954.

Ebrahimi AR, Zarei F, Khosroshahi RA. Effect of thermal oxidation process on fatigue behavior of Ti–4Al–2V alloy. Surf Coat Technol. 2008;203(3–4):199.

Zhang ZX, Dong H, Bell T, Xu B. The effect of treatment condition on boost diffusion of thermally oxidised titanium alloy. J Alloys Compd. 2007;431(1–2):93.

Dong H, Li XY. Oxygen boost diffusion for the deep-case hardening of titanium alloys. Mater Sci Eng A. 2000;280(2):303.

Dong H, Bell T. Enhanced wear resistance of titanium surfaces by a new thermal oxidation treatment. Wear. 2000;238(2):131.

Komotori J, Lee BJ, Dong H, Dearnley PA. Corrosion response of surface engineered titanium alloys damaged by prior abrasion. Wear. 2001;250–251,Part 2:1239.

Gomes JEL, Huntz AM. Correlation between the oxidation mechanism of titanium under a pure oxygen atmosphere, morphology of the oxide scale, and diffusional phenomena. Oxid Met. 1980;14(3):249.

Kofstad P. High-temperature oxidation of titanium. J Less Common Met. 1967;12(6):449.

Unnam J, Shenoy RN, Clark RK. Oxidation of commercial purity titanium. Oxid Met. 1986;26(3):231.

Li D, Yu ZT, Tang WS, Deng J. New alpha Ti alloy (Ti–4Al–2V) for marine engineering. J Mater Sci Technol. 2001;17(1):77.

Wang ZG, Zu XT, Lian J, Huang XQ, Wang L, Liu YZ, Wang LM. Characterization of oxide layers on Ti-2Al-2.5Zr and Ti-4Al-2V alloys oxidized at 300° C in a neutral water steam. J Alloys Compd. 2004;384(1):93.

Cullity BD, Stock SR. Elements of X-ray diffraction. Massachusetts: Addison-Wesley Publishing Company; 1956. p. 339.

Andersson S, Collen B, Kuylenstierna U, Magneli A. Phase analysis studies on the titanium-oxygen system. Acta Chem Scand. 1957;11(10):1641.

Dechamps M, Quivy A, Baur G, Lehr P. Influence of the distribution of the interstitial O atoms on the lattice parameters in dilute HCP Ti-O solid solutions (90–4,000 ppm at). Scr Metall. 1977;11(11):941.

Holmberg B. Disorder and order in solid solutions of oxygen in a-titanium. Acta Chem Scand. 1962;16(5):1245.

Acknowledgments

The authors would like to acknowledge the Sahand University of Technology, Tabriz, Iran, for the financial support and provision of laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omidbakhsh, F., Ebrahimi, A.R. Lattice parameters of Ti–4Al–2V alloy with thermal oxidation. Rare Met. 35, 149–153 (2016). https://doi.org/10.1007/s12598-015-0452-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0452-2