Abstract

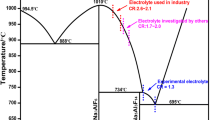

The cathodic behavior at tungsten electrode in Na3AlF6-Al2O3-LiF-based melt with various cryolite ratios was investigated by means of potentiodynamic cathodic polarization, potentiostatic electrolysis, chronopotentiometry, and open-circuit chronopotentiometry. The results show that the formation process of Al–W intermetallic compound is controlled by both diffusion and charge transfer when the cryolite ratio is below 2.5, and is completely controlled by diffusion when cryolite ratio is above 2.5. The deposition process of metal aluminum is completely charge-transfer controlled. Sodium vapor releases along with the deposition of metal aluminum as crylite ratio increases, which leads to a great influence on current efficiency. When the cryolite ratio is lower than 2.0, the critical cathodic current density of deposited aluminum at tungsten electrode is about 150 mA·cm−2, but the current density is above 200 mA·cm−2 under other experimental conditions. A higher cryolite ratio can cause a higher cathodic overvoltage. The relative content of Al layer is higher with the decrease of cryolite ratio, and Al layer easily strips into the molten salt when the cryolite ratio is higher than 2.5.

Similar content being viewed by others

References

Grjotheim K, Welch BJ. Aluminum Smelter Technology. 2nd ed. Dusseldorf: Aluminum-Verlag. 1988. 155.

Sum E, Skyllas-Kazacos M. An electrochemical study of aluminum deposition from molten NaF-AlF3-Al2O3 on a tungsten electrode. Electrochim Acta. 1989;34(5):677.

Nekrasov VN, Suzdaltsev AV, Limanovskaya OV, Khramov AP, Zaikov YP. Theoretical and experimental study of anode process at the carbon in KF-AlF3-Al2O3 melts. Electrochim Acta. 2012;75:296.

Cao DL, Qiu ZX, Wang JK, Shi ZN. Effects of additive lithium salts on aluminum electrolysis. Mater Rev. 2006;20(8):90.

Grjotheim K, Matiasovsky K, Malinovsky M. Influence of NaCl and LiF on the aluminum electrolyte. Electrochim Acta. 1970;15(2):259.

Qiu ZX. Aluminum Smelting with Prebaked Cell. Beijing: Metallurgical Industry; 2005. 108.

Chrenkova M, Danek V, Silny A. Density electrical conductivity and viscosity of low melting baths for aluminum electrolysis. In: Proceedings of TMS Annual Meeting. Warrendale; 1996. 227.

Pietrzyk S, Oblakowski R. Electrical conductivity of cryolite electrolytes during the liquid solid phase transition. In: Proceedings of TMS Annual Meeting. Washington; 2002. 231.

Bullard L, Przybycien DD. DTA determination of bath liquidus temperatures: effect of LiF. In: Proceedings of TMS Annual Meeting. New Orleans; 1986. 437.

Fellner P, Midtlyng S, Sterten A, Thonstad J. Electrical conductivity of low melting baths for aluminum electrolysis: the system Na3AlF6-2Li3AlF6- 2AlF3 and the influence of additions of Al2O3, CaF2 and MgF2. J Appl Electrochem. 1993;23(1):78.

Fellner R, Hives J, Korenko M. Cathodic overvoltage and the content of sodium and lithium in molten aluminum during electrolysis of cryolite-based melt. Electrochim Acta. 2001;46(4):2379.

Ljubomir V, Stipe G. Results of an experimental use of LiF in industrial pots (E-14). In: Proceedings of TMS Annual Meeting. Warrendale; 1990. 341.

Haarberg GM, Thonstad J, Pietryk S. The role of dissolved metal during electrodeposition of aluminum from cryolite–alumina melts. In: Proceedings of TMS Annual Meeting. Warrendale PA; 2002. 1083.

Wang XW, Peterson RD, Richards NE. Dissolved metals in cryolitic melts. In: Proceedings of TMS Annual Meeting. Warrendale; 1990. 323.

Wendt, Liu CS. The operation experience during the process of aluminum electrolysis after adding lithium salt. Light Met. 1986;3:28.

Gustavsen YT, Terje S. Effect of LiF on the vapour pressure over cryolite containing melts. In: Proceedings of TMS Annual Meeting. New Orleans; 2001. 357.

Naas T, Oye HA. Interactions of alkali metal with cathode carbon. In: Proceedings of TMS Annual Meeting, San Diego; 1999. 193.

Danielik V, Fellner P, Thonstad J. Content of sodium and lithium in aluminum during electrolysis of cryolite based melts. J Appl Electrochem. 1998;28(11):1265.

Frolov AV, Gusev AO, Zaikov YP, Khramov AP, Shurov NI, Tkacheva OY, Apisarov AP, Kovrov VA. Modified alumina-cryolite bath with high electrical conductivity and dissolution rate of alumina. In: Proceedings of TMS Annual Meeting. Orlando; 2007. 571.

Feng NX. Aluminum Electrolysis. Beijing: Northern Industry; 2006. 117.

Tao SH, Di YZ, Peng JP, Wang YW, Zhao K, Feng NX. Influence of LiF on cathodic process in Na3AlF6-Al2O3 molten salt electrolysis. Chem Ind Eng Soc Chin. 2013;65(2):633.

Sum E, Skyllas-Kazacos M. Aluminum dissolution in the NaF-AlF3-Al2O3 system: effects of alumina, temperature, gas bubbling and dissolved metal. J Appl Electrochem. 1989;19(4):485.

Sum E, Skyllas-Kazacos M. Aluminum dissolution in NaF-AlF3-Al2O3 systems. J Appl Electrochem. 1988;18(5):731.

Tellenbach JM, Landolt D. Electrochemical determination of current efficiency for aluminum deposition on solid substrates from cryolitic melts. J Appl Electrochem. 1988;18(4):639.

Wang W, Li ZA, Wang ZQ, Chen DH, Zhou L. Fused salt electrorefining of lanthanum. Rare Met. 2014;37(5):770.

Acknowledgments

The work was financially supported by the National Basic Research Program of China (No.2013CB632606-1) and the National Natural Science Foundation of China (No.51204044)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tao, SH., Di, YZ., Peng, JP. et al. Cathodic electrochemical behavior in Na3AlF6-Al2O3-LiF-based melts at tungsten electrode with various cryolite ratios. Rare Met. 37, 40–46 (2018). https://doi.org/10.1007/s12598-014-0392-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0392-2