Abstract

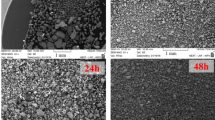

The effects of ytterbium (Yb) on microstructure and solidification behavior of Al–9.00 %Si–0.25 %Mg alloys were investigated. By optical microscope (OM) and scanning electron microscopy (SEM), it is found that the morphology of eutectic silicon changes from coarse plates to fine fibers by the addition of 0.7 %wt Yb. In addition, the grains of α-Al matrix are refined by Yb addition. Phase constitution of the alloy was analyzed by X-ray diffractometer (XRD) and energy dispersive spectroscopy (EDS) attached with SEM and mechanical properties were measured by hardness test. It is concluded that the Yb atoms are incorporated into the silicon by the adsorption at the solid–liquid growth front to cause the modification of eutectic silicon. Furthermore, the results of XRD and EDS analysis reveal that the Yb-containing phase forming in the alloys is Al3Yb.

Similar content being viewed by others

References

Dahle AK, Nogita K, McDonald SD, Dinnis C, McDonald LLu. Eutectic nucleation and growth in hypoeutectic Al-Si alloys at different strontium levels. Mater Sci Eng A. 2001;32(4):243.

Zhou YX, lv ZL, Zhao XC. The alterative of research and development of Al-Si alloy. Foundry Technol. 2004;25(1):13.

Lee YC, Dahle AK, StJohn DH. The effect of grain refinement and silicon content on grain formation in hypoeutectic Al–Si alloys. Mater Sci Eng A. 1999;259(1):43.

Makhlouf MM, Guthy HV. The aluminu–silicon eutectic reaction: mechanisms and crystallography. J Light Met. 2001;1(4):199.

Tsai YC, Chou CY, Lee SL, Lin CK, Lin JC, Lim SW. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al–7Si–0.35 Mg) aluminum alloys. J Alloy Compd. 2009;487(1–2):157.

Nogita K, Knuutinen A, McDonald SD, Dahle AK. Mechanisms of eutectic solidification in Al–Si alloys modified with Ba, Ca, Y and Yb. J Light Met. 2001;1(4):219.

Timpel M, Wanderka N, Schlesiger R. The role of strontium in modifying aluminium-silicon alloys. Acta Mater. 2012;60(9):3920.

Knuutinen A, Nogita K, McDonald SD, Dahle AK. Modification of Al–Si alloys with Ba, Ca, Y and Yb. J Light Met. 2001;1(4):229.

Yi H, Peng XD, Jiang JW, Li JC, Yu YQ. Microstructure, mechanical properties and corrosion resistance of Mg–9Li–3Al–1.6 Y alloy. Chin J Rare Met. 2013;37(6):863.

Lu SZ, Hellawell A. The mechanism of silicon modification in aluminum-silicon alloys: impurity induced twinning. Metall Trans A. 1987;18(10):1721.

Nogita K, McDonald SD, Dahle AK. Eutectic modification of Al–Si alloys with rare earth metals. Mater Trans. 2004;45(2):323.

Nogita K, Yasuda H, Yoshiya M, McDonald SD, Uesugi K, Takeuchi A, Suzuki Y. The role of trace element segregation in the eutectic modification of hypoeutectic Al–Si alloys. J Alloy Compd. 2010;489(2):415.

Nogita K, Dahle AK. Effects of boron on eutectic modification of hypoeutectic Al–Si alloys. Scr Mater. 2003;48(3):307.

Li B, Wang HW, Jie JC. Microstructure evolution and modification mechanism of the ytterbium modified Al–7.5%Si–0.45%Mg alloys. J Alloy Compd. 2011;509(7):3387.

Massalski TB, Murray JL, Bennett LH. Binary Alloy Phase Diagrams. Ohio: American Society for Metals; 1988. 196.

Binnewies M, Mike E. Thermochemical Data of Elements and Compounds. Weinheim: Wiley-VCH Verlag Gmbh; 2002. 783.

Robert Mortimer G. Physical Chemistry. Memphis, Amsterdam: Elsevier Academic Press; 2008. 173.

Knuutinen A, Nogita K, McDonald SD. Porosity formation in aluminium alloy A356 modified with Ba, Ca, Y and Yb. J Light Met. 2001;1(4):241.

Zhang LY, Jiang YH, Ma Z, Shan SF, Jia YZ, Fan CZ, Wang WK. Mechanical properties of cast A356 alloy, solidified at cooling rates enhanced by phase transition of a cooling medium. Mater Sci Eng A. 2007;448(1–2):361.

Li HL. The behavior of antimony in AI—Si casting alloys. Nanning: Guangxi University; 2006. 27.

Wan D. In-situ fibrous Si phase formation in as-cast Al-7Si hypoeutectic alloy under the combined effects of rapid solidification and modification. Rare Met Mater Eng. 2010;39(s1):216.

Zhang LY, Jiang YH, Ma Z, Shan SF, Jia YZ, Fan CZ, Wang WK. Effect of cooling rate on solidified microstructure and mechanical properties of aluminium- A356 alloy. J Mater Process Technol. 2008;207(1–3):107.

Kranenberg C, Johrendt D, Mewis A. Investigations about the stability range of the CaAl2Si2 type structure in the case of ternary silicides. Inorg Chem. 1999;625(11):1787.

Acknowledgments

This study was financially supported by the Natural Science Foundation Project of Chongqong, Chongqing Science and Technology Commission (No. cstc2012jjA70002) and the National Train Foundation Project of Innovation for Students, Southwest University, China (NO. 201410635002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jia, K., Yu, WB., Yao, JM. et al. Al–9.00 %Si–0.25 %Mg alloys modified by ytterbium. Rare Met. 36, 95–100 (2017). https://doi.org/10.1007/s12598-014-0378-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0378-0