Abstract

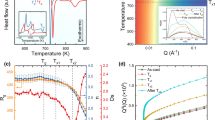

Bulk metallic glass composites (BMGCs) reinforced by micro- (spherical size of about 10 μm) and nano-sized (20–50 nm) Al3Zr crystals were synthesized by copper mold suction casting method. The isothermal crystallization of Cu40Zr44Ag8Al8 BMGCs in the supercooled liquid region was studied by differential scanning calorimeter (DSC), X-ray diffractometer (XRD), scanning electron microscopy (SEM), and transmission electron microscopy (TEM). The mechanisms for nucleation and growth of the crystalline phases precipitated in two-stage crystallization process and the effect of the isothermal treatment on the in situ crystalline phases were discussed. Results show that the BMGCs experience a primary crystallization process. Nano-sized Al3Zr and Cu10Zr7 phases precipitate from the amorphous matrix successively. Furthermore, isothermal annealing has no effect on the pre-existing particles in the as-cast sample, which creates a new method to synthesize BMGCs strengthened by duplex crystalline phases with a large size difference. And the reinforced phase could also be dominated with intention if the as-cast BMGCs preparation and isothermal treatment process can be controlled more accurately.

Similar content being viewed by others

References

Song M, Sun YY, He YH, Guo SF. Structure related hardness and elastic modulus of bulk metallic glass. J Appl Phys. 2012;111(5):053518.

Hsieh PJ, Yang LC, Su HC, Lu CC, Jang JSC. Improvement of mechanical properties in MgCuYNdAg bulk metallic glasses with adding Mo particles. J Alloys Compd. 2010;504:98.

Sun BR, Zhan ZJ, Liang B, Zhang RJ, Wang WK. Fracture characteristics of bulk metallic glass under high speed impact. Chin Phys B. 2012;21(5):056101.

Pasko A, Ochin P, Nowak S, Champion Y. Synthesis and characterization of amorphous Zr-based alloys with Ta and W additions. J Alloys Compd. 2009;483(1):120.

Jang JSC, Jian SR, Pan DJ, Wu YH, Huang JC, Nieh TG. Thermal and mechanical characterizations of a Zr-based bulk metallic glass composite toughened by in situ precipitated Ta-rich particles. Intermetallics. 2010;18(4):560.

Zheng XL, Zhu ZH, Li XM. The absorbing properties of Fe73.5Cu1Nb3Si13.5B9 amorphous powder/S-glass fiber-reinforced epoxy composite panels. Rare Met. 2013;32(3):294.

Jang JSC, Li JB, Lee SL, Chang YS, Jian SR, Huang JC, Nieh TG. Prominent plasticity of Mg-based bulk metallic glass composites by ex situ spherical Ti particles. Intermetallics. 2012;30:25.

Jang JSC, Li TH, Jian SR, Huang JC, Nieh TG. Effects of characteristics of Mo dispersions on the plasticity of Mg-based bulk metallic glass composites. Intermetallics. 2011;19(5):738.

Jang JSC, Li WJ, Li TH, Jian SR, Huang JC, Nieh TG. Thermoplastic forming ability of a Mg-base bulk metallic glass composites reinforced with porous Mo particles. Intermetallics. 2010;18(10):1964.

Mondal K, Ohkubo T, Toyama T, Nagai Y, Hasegawa M, Hono K. The effect of nanocrystallization and free volume on the room temperature plasticity of Zr-based bulk metallic glasses. Acta Mater. 2008;56(18):5329.

Li JB, Jang JSC, Li C, Jian SR, Tsai PH, Hwang JD, Huang JC, Nieh TG. Significant plasticity enhancement of ZrCu-based bulk metallic glass composite dispersed by in situ and ex situ Ta particles. Mater Sci Eng A. 2012;551:249.

Li JB, Zhang HZ, Jang JSC, Jian SR, Li C, Huang JC, Nieh TG. Viscous flow and thermoplastic forming ability of a Zr-based bulk metallic glass composite with Ta dispersoids. J Alloys Compd. 2012;536:165.

Gu J, Song M, Ni S, Guo SF, He YH. Effects of annealing on the hardness and elastic modulus of a Cu36Zr48Al8Ag8 bulk metallic glass. Mater Des. 2013;47:706.

Xie HW, Li YC, Liao SZ, Hodgson P, Wen C. Plastic deformation in a partially crystallized Zr-based BMG under Vickers indenter. J Alloys Compd. 2009;484(1):886.

Xing LQ, Eckert J, Löser W, Schultz L, Herlach DM. Crystallization behaviour and nanocrystalline microstructure evolution of a Zr57Cu20Al10Ni8Ti5 bulk amorphous alloy. Philos Mag A. 1999;79(5):1095.

Li YQ, Song M, He YH. Effect of quenching mode on the mechanical properties of a Zr64Al10Ni15Cu11 metallic glass. Mater Des. 2010;31(7):3555.

Laws KJ, Gun B, Ferry M. Mechanical stability of Ca65Mg15Zn20 bulk metallic glass during deformation in the supercooled liquid region. Mater Sci Eng A. 2008;480(1):198.

Antonione C, Spriano S, Rizzi P, Baricco M, Battezzati L. Phase separation in multicomponent amorphous alloys. J Non-Cryst. 1998;232:127.

Basu J, Nagendra N, Li Y, Ramamurty U. Microstructure and mechanical properties of a partially crystallized La-based bulk metallic glass. Philos Mag. 2003;83(15):1747.

Takeuchi A, Inoue A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element (overview). Mater Trans. 2005;46(12):2817.

Liu Y, Blandin JJ, Suery M, Kapelski G. Effect of cooling rate on the microstructure and microhardness of the CuZrAgAl alloy. Mater Charact. 2012;70:8.

Liu Y, Blandin JJ, Kapelski G, Suéry M. High temperature deformation of a Cu40Zr44Ag8Al8 bulk metallic glass. Mater Sci Eng A. 2011;528(10):3748.

Zander D, Heisterkamp B, Gallino I. Corrosion resistance of Cu–Zr–Al–Y and Zr–Cu–Ni–Al–Nb bulk metallic glasses. J Alloys Compd. 2007;434–435:234.

Li DK, Zhu ZW, Zhang HF, Wang AM, Hu ZQ. The influence of Zr substitution for Nb on the corrosion behaviors of the Ni–Nb–Zr bulk metallic glasses. Sci China Phys Mech Astron. 2012;55(12):2362.

Gebert A, Concustell A, Greer AL, Schultz L, Eckert J. Effect of shot-peening on the corrosion resistance of a Zr-based bulk metallic glass. Scr Mater. 2010;62(9):635.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Nos. 51061008 and 50961008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, XY., Yuan, ZZ., Feng, XL. et al. Isothermal nanocrystallization behavior of bulk metallic glass composites in supercooled liquid region. Rare Met. 36, 919–924 (2017). https://doi.org/10.1007/s12598-014-0358-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0358-4