Abstract

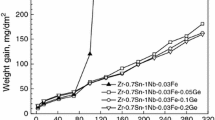

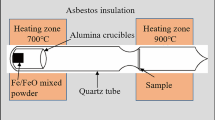

The surface of Tb0.3Dy0.7Fe2 alloys was modified by microwave electron-cyclotron-resonance chemical vapor deposition (MW-ECR-CVD) and ion implantation technology, respectively. The microstructure and corrosion resistance of nitrided layers were investigated by means of optical microscope (OM), X-ray diffractomer (XRD), auger electron spectroscopy (AES), and electrochemical workstation. After modified by MW-ECR-CVD, the nitrogen concentration of the nitrided layers decreases gradually with the depth increasing, while the nitrogen concentration modified by ion implantation process exhibits Gaussian distribution. The self-corrosion electric potential of the sample modified by ion implantation is higher than that modified by MW-ECR-CVD, which reveals that the samples modified by ion implantation process have a better resistance to corrosion. The magnetostrictions are assessed for the samples placed in the air for one year, which further confirms that the ion implantation process is more helpful to maintain the magnetostrictions.

Similar content being viewed by others

References

Clark AE. Magnetostrictive Rare Earth-Fe2 Compounds. In: Wohlfarth EP, editor. Ferromagnetic Materials. Amsterdam: North-Holland; 1980. 531.

Hristoforou E, Ktena A. Magnetostriction and magnetostrictive materials for sensing applications. J Magn Magn Mater. 2007;316(3):372.

Grunwald A, Olabi AG. Design of a magnetostrictive (MS) actuator. Sens Actuators A. 2008;144(1):161.

Olabi AG, Grunwald A. Design and application of magnetostrictive materials. Mater Des. 2008;29(1):469.

Li KS, Li HW, Yan H, Yu DB, Wang FY, Zhang SR, Zhang GC. Surface modification of (Tb0.3Dy0.7)Fel.95 alloy by ion nitriding process. J Rare Earths. 2009;27(2):240.

Li KS, Yu DB, Li HW, Zhang SR, Wang PF. A surface modifying technology on rare earth giant magnetostrictive materials. Chinese Patent; No. ZL 200510137232.2. 2005

Zhang SR, Li KS, Yu DB, Li HW, Li YS. Surface modification of TbDyFe alloys by ionic nitriding process. J Chin Soc Rare Earths. 2007;25(6):126.

Zhou T, Li YC, Li ZY, Liu Y, Zhou KC. Research on oxidation-resistance property of Ni–Fe–X alloys. Mater Sci Eng Powder Metal. 2003;8(1):68.

Wu DG, Yan SH, Li ZG, Wang ZQ, Wang XS. Effect of samarium on corrosion behavior of as-cast AZ92 magnesium alloy. Chin J Rare Met. 2013;37(2):199.

Luo P, Wang S-N, Zhao T-T, Li Y. Surface characteristics, corrosion behavior, and antibacterial property of Ag-implanted NiTi alloy. Rare Met. 2013;32(2):113.

Leng CY, Zhou R, Zhang X. Corrosion resistance of Ta+-implanted Ti6Al4V alloy in Hank’s solution. Nucl Tech. 2012;35(2):93.

Wang Q, Meng DQ, Liu KZ, Xiao H. Initial oxidation study of pure iron surface with implantation of carbon ions. China Surf Eng. 2011;24(2):65.

Liu HX, Meng CL, Lin B, Jiang YH, Zhou RF. Corrosion resistance and mechanical property of AZ31 magnesium alloy by N/Ti duplex ion implantation. Trans Mater Heat Treat. 2011;32(8):137.

Feng C, Li N, Li S, Huo QM, Li MH, Zhan Q, Li BH, Jiang Y, Yu GH. Modification of magnetic properties in SmCo films by controlling crystallization and phase transition. Sci China-Phys Mech Astron. 2012;55(10):1798.

Ma L, Liu ZW, Zeng DC, Yu HY, Zhong XP, Zhang XZ. Structure and magneto-electrical properties of Fe–C films prepared by magnetron sputtering. Sci China-Phys Mech Astron. 2012;55(9):1594.

Wang SX, Xiong BJ, Tian XB, Yang SQ. Surface modification of hard alloy by C + Cr ion implantation. Hot Work Technol. 2011;40(4):122.

Nakao S. Structural changes of Si surfaces by nitrogen implantation using plasma based ion implantation. Nucl Instrum Methods Phys Res B. 2009;267(1):1303.

Acknowledgments

This research was financially supported by the National High Technology Research and Development Program of China (No.2011AA03A404) and the National Natural Science Foundation of China (No.50801006). The authors wish to acknowledge Hai-Bo Wang for the development and fabrication of the giant magnetostrictive materials used for the experiments in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, HC., Zhang, SR., Yu, DB. et al. Structure and properties of Tb0.3Dy0.7Fe2 alloys modified by surface nitriding. Rare Met. 40, 1198–1202 (2021). https://doi.org/10.1007/s12598-014-0357-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0357-5