Abstract

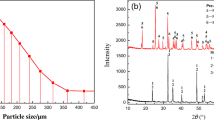

In this paper, the thermodynamics of the reduction of ilmenite using multiple gases (H2/CO) was calculated. It is found that the metallization rate of 20.1 %–98.8 %, H2 consumption rate of 43.0 %–99.1 %, and carbon deposition amount of 5.7 × 10−7 − 0.49 mol can be obtained based on the conditions of hydrogen volume fraction of 10 %–90 % and temperature of 450–1200 °C. Experimental study was also carried out using synthetic ilmenite as initial materials and reduced in a static bed reactor at 1100 °C. The metallization rate reaches 97 % when the multiple gas (70 % H2/10 % CO/20 % Ar) flow rate is 120 ml·min−1. A thermogravimetric analyzer was used to measure the variation of sample weight caused by the deposition of solid carbon. The amount of carbon deposited during experiments reaches its maximum while the original hydrogen volume content is 20 %. The experimental results are well consistent with the thermodynamic analysis.

Similar content being viewed by others

References

Zhang HM, He XB, Qu XH, Liu Q, Shen XY. Microstructure and thermal properties of copper matrix composites reinforced with titanium-coated graphite fibers. Rare Met. 2013;1(32):75.

Xiao JH, Fan SP, Wang Z, Xu LH, Wang DZ. Comprehensive recovery of low grade tungsten-titanium polymetallic ore in Hubei. Chin J Rare Met. 2013;37(4):656.

Fan MT, Yang HB, Cao JM. Deformation twinning evolution and stability of commercially pure titanium. Chin J Rare Met. 2013;37(2):192.

El-Guindy MI, Davenport WG. Kinetics and mechanism of ilmenite reduction with graphite. Metall Mater Trans B. 1970;1(6):1729.

Gupta SK, Rajakumar V, Grieveson P. Kinetics of reduction of ilmenite with graphite at 1000–1100 °C. Metall Mater Trans B. 1987;18B(12):713.

Gupta SK, Rajakumar V, Grieveson P. The influence of weathering on the reduction of ilmenite with carbon. Metall Mater Trans B. 1989;20B(5):735.

Welham NJ, Williams JS. Carbothermic reduction of ilmenite (FeTiO3) and rutile (TiO2). Metall Mater Trans B. 1999;30B(12):1075.

Kucukkaragoz CS, Eric RH. Solid state reduction of a natural ilmenite. Miner Eng. 2006;19(3):334.

Kelly RM, Rowson NA. Microwave reduction of oxidized ilmenite concentrates. Miner Eng. 1995;8(11):1427.

Zhang G, Ostrovski O. Effect of preoxidation and sintering on properties of ilmenite concentrates. Int J Miner Process. 2002;64(4):201.

Chen Y, Hwang T, Williams JS. Ball milling induced low-temperature carbothermic reduction of ilmenite. Mater Lett. 1996;28(1–3):55.

Welham NJ. A parametric study of the mechanically activated carbothermic reduction of ilmenite. Miner Eng. 1996;9(12):1189.

Lei Y, Li Y, Peng JH, Guo SH, Li W, Zhang LB, Wan RD. Carbothermic reduction of Panzhihua oxidized ilmenite in a microwave field. ISIJ Int. 2011;51(3):337.

Kim Y, Worrell E. International comparison of CO2 emission trends in the iron and steel industry. Energy Policy. 2002;10(30):827.

Duc NH, Chauvy F, Herri J. CO2 capture by hydrate crystallization-a potential solution gas emission of steelmaking industry. Energy Convers Manage. 2007;4(48):1313.

Meinshausen M, Meinshausen N, Hare W, Raper SCB, Frieler K, Knutti R, Frame DJ, Allen MR. Greenhouse-gas emission targets for limiting global warming to 2 °C. Nature. 2009;909(458):1158.

Zhao Y, Shadman F. Reduction of ilmenite with hydrogen. Ind Eng Chem Res. 1991;30(9):2080.

Vijay PL, Venugopalan R, Sathiyamoorthy D. Preoxidation and hydrogen reduction of ilmenite in a fluidization bed reactor. Metall Mater Trans B. 1996;27(5):731.

Jozwiak WK, Kaczmarek E, Maniecki TP, Ignaczak W, Maniukiewicz W. Reduction behavior of iron oxides in hydrogen and carbon monoxide atmospheres. Appl Catal A Gen. 2007;326(1):17.

Pineau A, Kanari N, Gaballah I. Kinetics of reduction of iron oxides by H2. Part I. Low temperature reduction of hematite. Termochim Acta. 2006;447(1):89.

Pineau A, Kanari N, Gaballah I. Kinetics of reduction of iron oxides by H2. Part II. Low temperature reduction of magnetite. Termochim Acta. 2007;456(2):75.

Xu KD. Iron and steel industry development and technological innovation in China. Iron Steel. 2008;43(2):2.

Yang ZB, Ding WZ, Zhang YY, Lu XG, Zhang YW, Shen PJ. Catalytic partial oxidation of coke oven gas to syngas in an oxygen permeation membrane reactor combined with NiO/MgO catalyst. Int J Hydrogen Energy. 2010;35(12):6239.

Cheng HW, Lu XG, Zhang YW, Ding WZ. Hydrogen production by reforming of simulated hot coke oven gas over nickel catalysts promoted with lanthanum and cerium in a membrane reactor. Energy Fuel. 2009;23(6):3119.

Cheng HW, Zhang YW, Lu XG, Ding WZ, Li Q. Hydrogen production from simulated hot coke oven gas by using oxygen-permeable ceramics. Energy Fuel. 2009;23:414.

Yang ZB, Zhang YW, Zhang YY, Ding WZ, Shen PJ, Liu Y, Zhou YD, Huang SQ. Hydrogen production from coke oven gas by methane reforming: thermodynamic analysis and experimental study. Acta Phys Sin. 2010;26(2):350.

Azis MM, Jerndal E, Leion H, Mattisson T, Lyngfelt A. On the evaluation of synthetic and natural ilmenite using syngas as fuel in chemical-looping combustion (CLC). Chem Eng Res Des. 2010;88(11):1505.

Dai YD, Guo XM, Zhang JY. Microreaction mechanism of the reduction of ilmenite to iron by H2 + ion implantation. J Univ Sci Technol B. 2007;29(4):373.

Sun K, Takahashi R, Yagi J. Reduction kinetics of cement-bonded natural ilmenite pellets with hydrogen. ISIJ Int. 1992;32(4):496.

Longbottom RJ, Ostrovski O, Park E. Formation of cementite from titanomagnetite ore. ISIJ Int. 2006;46:641.

Gaikwad AV, Rout TK, Van der Plas D, Dennis RV, Banerjee S, Benito SP, Lefferts L. Carbon nanotube/carbon nanofiber growth from industrial by-product gases on low-and high-alloy steels. Carbon. 2012;50(12):4722.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51074105) and China National Funds for Distinguished Young Scientists (No. 51225401).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, W., Lu, XG., Zou, XL. et al. Multiple gaseous reduction of ilmenite: thermodynamic and experimental study. Rare Met. 34, 888–894 (2015). https://doi.org/10.1007/s12598-014-0264-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0264-9