Abstract

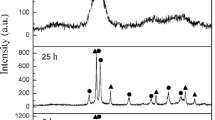

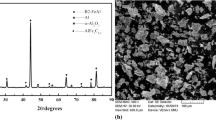

In this study, it was reported a novel approach for joining Cf/Al composites and TiAl intermetallic by self-propagating high-temperature synthesis (SHS). Mixed powders of 14Al–2Ni–3CuO were used as the SHS interlayer, and differential thermal analysis test of Al–Ni–CuO interlayer was conducted to analyze the exothermic characteristic. Sound joint was got by SHS joining under the conditions of 600 °C, 30 min, and 5 MPa. The joint was characterized by scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), and X-ray diffraction (XRD). TiAl3 and NiAl3 are, respectively, formed in the TiAl/interlayer and Cf/Al/interlayer interfaces. Reaction products of Ni2Al3, NiAl3, Al2O3, and Cu were observed in the interlayer. And the formation mechanism of SHS joining was investigated.

Similar content being viewed by others

References

Li SH, Chao CG. Effects of carbon fiber/Al interface on mechanical properties of carbon-fiber-reinforced aluminum-matrix composites. Metall Mater Trans A. 2004;35(7):2153.

Zhou YX, Yang W, Xia YM, Mallick PK. An experimental study on the tensile behavior of a unidirectional carbon fiber reinforced aluminum composite at different strain rates. Metall Mater Trans A. 2003;362(1–2):112.

Wu XH. Review of alloy and process development of TiAl alloys. Intermetallics. 2006;14(10–11):1114.

Song XG, Cao J, Chen HY, Wang YF, Feng JC. Brazing TiAl intermetallics using TiNi-V eutectic brazing alloy. Mater Sci Eng. 2012;551:133.

Imayev RM, Imayev VM, Oehring M, Appel F. Alloy design concepts for refined gamma titanium aluminide based alloys. Intermetallics. 2007;15(4):451.

Li ZR, Feng JC, Cao J. Vacuum diffusion bonding of TiB2 cermet to TiAl-based alloys. Mater Sci Tech-Lond. 2004;20(12):1666.

Lu X, Zhu LP, Liu CC, Zhang L, Wu M, Qu XH. Fabrication of micro-fine high Nb-containing TiAl alloyed powders by fluidized bed jet milling. Rare Met. 2012;31(1):1.

Liang WZ, Ji YD, Nan TX, Huang J, Zeng HZ, Du H, Chen CL, Lin Y. Optimized growth and dielectric properties of barium titanate thin films on polycrystalline Ni foils. Chin Phys B. 2012;21(6):067701.

Zhang ZF, Jia XP, Liu XB, Hu MH, Li Y, Yan BM, Ma HA. Effects of aluminum additive on diamond crystallization in the Fe–Ni–C system under high temperature and high pressure conditions. Sci China-Phys Mech Astron. 2012;55(5):781.

Biswas A. Porous NiTi by thermal explosion mode of SHS: processing, mechanism and generation of single phase microstructure. Acta Mater. 2005;53(5):1415.

Lai W, Munir ZA, McCoy BJ, Risbud SH. Centrifugally-assisted combustion synthesis of functionally-graded materials. Scripta Mater. 1997;36(3):331.

Zarrinfar N, Shipway PH, Kennedy AR, Saidi A. Carbide stoichiometry in TiC x and Cu–TiC x produced by self-propagating high-temperature synthesis. Scripta Mater. 2002;46(2):121.

Feng JC, Cao J, Li ZR. Microstructure evolution and reaction mechanism during reactive joining of TiAl intermetallic to TiC cermet using Ti-Al-C-Ni interlayer. J Alloys Compd. 2007;436(1–2):298.

Cao J, Feng JC, Li ZR. Effect of reaction heat on reactive joining of TiAl intermetallics using Ti-Al-C interlayers. Scripta Mater. 2007;57(5):421.

Duckham A, Spey SJ, Wang J, Reiss ME, Weihs TP, Besnoin E, Knio OM. Reactive nanostructured foil used as a heat source for joining titanium. J Appl Phys. 2004;96(4):2336.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51075101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, ZR., Feng, GJ., Xu, K. et al. Microstructure and formation mechanism of SHS joining between Cf/Al composites and TiAl intermetallic with Al–Ni–CuO interlayer. Rare Met. 34, 17–21 (2015). https://doi.org/10.1007/s12598-013-0193-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0193-z