Abstract

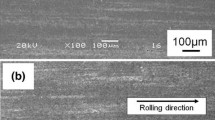

The stripe cracks which formed along rolling direction on the surface of Ti–4Al–2V alloy cold-rolled sheet were observed by stereoscope, scanning electron microscope (SEM), and energy-dispersive spectrometer (EDS). Morphology analysis indicates that cracks are dominantly in zigzag shape, with 10–30 mm in length and less than 10 μm in depth, and there is no evidence of crack tips. Chemical composition analysis shows that crack regions feather high oxygen concentration while smooth surface is at normal oxygen level. It is obvious that the occurrence of strip cracks is mainly related to residual oxide on the surface of Ti–4Al–2V alloy cold-rolled sheet.

Similar content being viewed by others

References

Boyer R, Collings EW, Welsch G. Materials Properties Handbook: Titanium Alloys. Ohio: ASM International, Materials Park; 1994. 165.

Li D, Yu ZT, Tang WS, Deng J. New α Ti alloy (Ti-4Al-2V) for marine engineering. J Mater Sci Technol. 2001;17(1):77.

Yu Z, Zhou L, Gu H. In situ SEM observation of monotonic and cyclic deformed structure in Ti-2Al-2.5Zr alloy. J Mater Sci Technol. 2001;17(1):37.

Yu ZT, Zhou L, Deng J, Gu H. Investigation on monotonic and cyclic stress-strain characteristics of Ti-2Al-2.5Zr alloy. Mater Sci Eng, A. 2000;280(1):192.

Yu ZT, Zhou L, Deng J, Gu H. Study of texture evolution of Ti-2Al-2.5Zr alloy in tube and plate. Rare Metal Mater Eng. 2000;29(2):86.

Yu ZT, Zhou L, Deng J, Gu H. Mechanisim of recrystallization characteristics and dynamics of Ti-2Al-2.5Zr alloy. Rare Metal Mater Eng. 1999;28(6):340.

Sarrazin P, Motte F, Besson J. Oxidation mechanism of titanium and of alloy TA6V4 by water vapor. J Less-Common Met. 1978;59(2):111.

Kusabiraki K, Sugihara T, Ooka T. Oxidation behaviors of pure titanium at high temperatures in Ar-H2O atmospheres. Tetsu-to-Hagane. 1992;78(5):829.

Motte F, Coddet C, Sarrazin P, Azzopardi M, Besson J. A comparative study of the oxidation with water vapor of pure titanium and of Ti-6Al-4V. Oxidation Metals. 1976;10(2):113.

Zu XT, Wang ZG, Feng XD, Huo YZ, Lin LB, Huang XQ, Li YL. The effect of pre-oxidation on the oxidation behavior of Ti-alloy at 300 °C in an alkaline steam. Surf Coat Technol. 2001;140(2):161.

Zu XT, Feng XD, Wang ZG, Zeng GT, Lin LB, Li YL, Huang XQ. Characterization of the oxide scale on a Ti-2Al-2.5Zr alloy with and without pre-oxidation in an alkaline steam at 300 °C. Surf Coat Technol. 2001;148(2–3):216.

Wang ZG, Zu XT, Lian J, Huang XQ, Wang L, Liu YZ, Wang LM. Characterization of oxide layers on Ti–2Al–2.5Zr and Ti–4Al–2V alloys oxidized at 300 °C in a neutral water steam. J Alloy Compd. 2004;384(1–2):93.

Zu XT, Wang ZG, Feng XD, Zhang CF, Zhu S, Yu Q. Surface characterization of a Ti–2Al–2.5Zr alloy by nitrogen ion implantation. J Alloy Compd. 2003;351(1–2):114.

Wang ZG, Zu XT, Xiang X, Zhu S, Wang LM. Surface modification of Ti–4Al–2V alloy by nitrogen implantation. J Mater Sci. 2006;41(11):3363.

Omidbakhsh F, Ebrahimi AR, Mousavi SH, Khosroshahi RA, Nazarpour S. Effect of oxygen boost diffusion treatment on fatigue behavior of Ti–4Al–2V alloy. Surf Coat Technol. 2011;205(8–9):2954.

Dong H, Li XY. Oxygen boost diffusion for the deep-case hardening of titanium alloys. Mater Sci Eng, A. 2000;280(2):303.

Ebrahimi AR, Zarei F, Azarikhosroshahi R. Effect of thermal oxidation process on fatigue behavior of Ti–4Al–2V alloy. Surf Coat Technol. 2008;203(3–4):199.

Huang DM. Research on oxidation behavior of CP titanium TA2. Iron Steel Vanadium Titanium. 2010;31(1):11.

Yang XF, Huang DM, Wei QF. Study on high temperature oxidation behaviors of titanium alloy TC4 in laboratory. Iron Steel Vanadium Titanium. 2010;31(4):16.

Acknowledgments

This study was financially supported by the Sichuan Provincial Key Technology R&D Program (No. 2013GZX0136).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, DM., Yang, XF., Wei, QF. et al. Causes of surface stripe cracks of Ti–4Al–2V alloy cold-rolled sheet. Rare Met. 33, 522–526 (2014). https://doi.org/10.1007/s12598-013-0132-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0132-z