Abstract

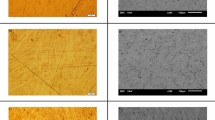

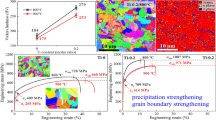

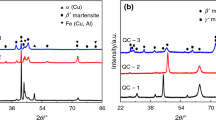

The microstructures and mechanical properties of Ti–47 at% Ni–3 at% Fe shape memory alloy wire under the condition of severe cold-drawing at room temperature and different postdeformation annealing processes were intensively investigated using transmission electron microscope (TEM), X-ray diffraction (XRD), Vickers microhardness tester and electron tensile tester. It is indicated that the structure of the alloy evolves into a predominant amorphous structure with a trace of nanocrystalline B2 phase after the cold-drawing of 76 % areal reduction. Postdeformation annealing process exerted significant influence on the microstructure and mechanical properties. Crystallization occurs when the cold-drawn wire was annealed at 300 °C for 30 min. The ultimate tensile strength and ductility as well as the superelasticity of the wire are improved significantly by cold-drawing plus postdeformation annealing.

Similar content being viewed by others

References

Lei X, Wang R. The effect of annealing and cold-drawing on the super-elasticity of the Ni–Ti shape memory alloy wire. Mod Appl Sci. 2010;4(12):109.

Zhu P, Hong D, Wu JH, Qian GR. Kinetics of forward extraction of Ti(IV) from H2SO4 medium by P507 in kerosene using the single drop technique. Rare Met. 2011;30(1):1.

Huang JY, Zhu YT, Liao XZ, Valiev RZ. Amorphization of Ti–Ni induced by high-pressure torsion. Phil Mag Lett. 2004;84(3):183.

Pushin VG, Stolyarov VV, Valiev RZ, Lowe TC, Zhu YT. Nanostructured Ti–Ni-based shape memory alloys processed by severe plastic deformation. Mater Sci Eng A. 2005;410–411(1–2):386.

Sergueeva AV, Song C, Valiev RZ, Mukherjee AK. Structure and properties of amorphous and nanocrystalline Ni–Ti prepared by severe plastic deformation and annealing. Mater Sci Eng A. 2003;339(1–2):159.

Waitz T, Kazykhanov V, Karnthaler HP. Martensitic phase transformations in nanocrystalline Ni–Ti studied by TEM. Acta Mater. 2004;52(1):137.

Nakayama H, Tsuchiya K, Umemoto M. Crystal refinement and amorphisation by cold rolling in Ti–Ni shape memory alloys. Scripta Mater. 2001;44(8–9):1781.

Khmelevskaya IYu, Prokoshkin SD, Trubitsyna IB, Belousov MN, Dobatkin SV, Tatyanin EV, Korotitskiy AV, Brailovski V, Stolyarov VV, Prokofiev EA. Structure and properties of Ti–Ni-based alloy after equal-channel angular pressing and high-pressure torsion. Mater Sci Eng A. 2008;481–482(1–2):119.

Prokoshkin SD, Khmelevskaya IYu, Dobatkin SV, Trubitsyna IB, Tatyanin EV, Stolyarov VV, Prokofiev EA. Alloy composition temperature, pressure and post-deformation annealing effects in severely deformed Ti–Ni-based shape memory alloys. Acta Mater. 2005;53(9):2703.

Chang SH, Wu SK, Chang GH. Grain size effect on multiple-stage transformations of a cold-rolled and annealed equiatomic Ti–Ni alloy. Scripta Mater. 2005;52(12):1341.

Tsuchiya K, Inuzuka M, Tomus D, Hosokawa A, Nakayama H, Morii K, Todaka Y, Umemoto M. Martensitic transformation in nanostructured Ti–Ni shape memory alloy formed via severe plastic deformation. Mater Sci Eng A. 2006;438–440(2):643.

Sun CY, Liu JR, Li R, Zhang QD, Dong JX. Constitutive relationship of IN690 superalloy by using uniaxial compression tests. Rare Met. 2011;30(1):81.

Tsuchiya K, Hada Y, Koyano T, Nakajima K, Ohnuma M, Koike T, Todaka Y, Umemoto M. Production of Ti–Ni amorphous/nanocrystalline wires with high strength and elastic modulus by severe cold-drawing. Scripta Mater. 2009;60(9):749.

Wu SK, Lin HC, Yen YC. A study on the wire drawing of Ti–Ni shape memory alloys. Mater Sci Eng A. 1996;215(1–2):113.

Zheng YF, Huang BM, Zhang JX, Zhao LC. The microstructure and linear superelasticity of cold-drawn Ti–Ni alloy. Mater Sci Eng A. 2000;279(1–2):25.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 50921003) and the Industry, Education and Research Projects of the China Aviation Industrial (No.cxy2012BH04).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Geng, HF., Liu, FS. Microstructures of Ti–Ni–Fe wire after severe cold-drawing and annealing. Rare Met. 32, 550–554 (2013). https://doi.org/10.1007/s12598-013-0091-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0091-4