Abstract

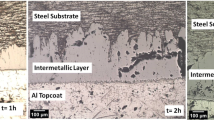

The hot dipping process of pure aluminum on H13 steel substrates followed by plasma electrolytic oxidation (PEO) was studied to form alumina ceramic coatings for protective purpose. H13 steel bars were first dipped in pure aluminum melts, and then, a reactive iron-aluminum intermetallic layer grew at the interface between the melt and the steel substrate. The reactive layer was mainly composed of intermetallic Fe-Al (Fe2Al5); the thickness of aluminum layer and Fe-Al intermetallic layer were mainly influenced by dipping time (1.5∼12.0 min) and dipping temperature (710∼760 °C). After PEO process, uniform Al2O3 ceramic coatings were deposited on the surface of aluminized steel. The element distribution, phase composition and morphology of the aluminized layer, and the ceramic coatings were characterized by SEM/EDS and XRD. The distribution of hardness across the composite coating is demonstrated, and the maximum value reaches 1864 HV. The thermal shock resistance of the coated sample is also well improved.

Similar content being viewed by others

References

Chen Z.W., Formation and progression of die soldering during high pressure die casting, Mater. Sci. Engin. A, 2005, 397(1–2): 356.

Shih T.S., and Tu S.H., Interaction of steel with pure Al, Al-7Si and A356 alloy, Mater. Sci. Engine. A, 2007, 455: 349.

Nazari K.A., and Shabestari S.G., Effect of micro alloying elements on the interfacial reactions between molten aluminum alloy and tool steel, J. Alloys. Compd., 2009, 478(1–2): 523.

Tentardini E.K., Kunrath A.O., Aguzzoli C., Castro M., Moore J.J., and Baumvol I.J.R., Soldering mechanisms in materials and coatings for aluminum die casting, Surf. Coat. Technol., 2008, 202(16): 3764.

Shen D.J., Wang Y.L., Nash P., and Xing G.Z., Microstructure, temperature estimation and thermal shock resistance of PEO ceramic coatings on aluminum, J. Mater. Process. Technol., 2008, 205(1–3): 477.

Li H.X., Rudnev V.S., Zheng X.H., Yarovaya T.P., and Song R.G., Characterization of Al2O3 ceramic coatings on 6063 aluminum alloy prepared in borate electrolytes by micro-arc oxidation, J. Alloy. Compd., 2008, 462(1–2): 99.

Karpushenkov S.A., Shchukin G.L., Belanovich A.L., Savenko V.P., and Kulak A.I., Plasma electrolytic ceramic-like aluminum oxide coatings on iron, J. Appl. Electrochem., 2010, 40(2): 365.

Wang Y.L., Jiang Z.H., Yao Z.P., and Tang H., Microstructure and corrosion resistance of ceramic coating on carbon steel prepared by plasma electrolytic oxidation, Surf. Coat. Technol., 2010, 204(11): 1685.

Sundararajan G., Wasewar N.P., and Ravi N., The influence of the coating technique on the high cycle fatigue life of alumina coated Al 6061 alloy, Trans. IIM., 2010, 63(2–3): 203.

Waseker N.P., Jyothirmayi A., Krishna L.R., and Sundararajan G, Effect of micro arc oxidation coatings on corrosion resistance of 6061-Al alloy, J. Mater. Engine. Perform., 2008, 17(5): 708.

Nie X., Wang L., Konac E, and Alpas A.T., Tribological behaviour of oxide/graphite composite coatings deposited using electrolytic plasma process, Surf. Coat. Technol., 2004, 188: 207.

Wang Y.L., Jiang Z.H., and Yao Z.P., Preparation and properties of ceramic coating on Q235 carbon steel by plasma electrolytic oxidation, Current Applied Physics, 2009, 9(5): 1067.

Hussein R.O., Nie X., and Northwood D.O., Influence of process parameters on electrolytic plasma discharging behaviour and aluminum oxide coating microstructure, Surf. Coat. Technol., 2010, 205(6): 1659.

Xue W.B., Deng Z.D., Lai Y.C., and Chen R.Y., Analysis of phase distribution for ceramic coatings formed by microarc oxidation on aluminum alloy, J. Amer. Ceram. Soc., 1998, 81(5): 1365.

Dunleavy C.S., Golosnoy I.O., Curran J.A., and Clyne T. W., Characterisation of discharge events during plasma electrolytic oxidation, Surf. Coat. Technol., 2009, 203(22): 3410.

Chen Z.T., Li G., Wu Z. Q., and Xia Y., The crack propagating behavior of composite coatings prepared by PEO on aluminized steel during in situ tensile processing, Mater. Sci. Engine. A., 2011, 528(3): 1409.

Cheng W.J., and Wang C.J., Study of microstructure and phase evolution of hot-dipped aluminide mild steel during high-temperature diffusion using electron backscatter diffraction, Appl. Surf. Sci., 2011, 257(10): 4663.

Wang D.Q., Phase evolution of an aluminized steel by oxidation treatment, Appl. Surf. Sci., 2008, 254(10): 3026.

Rongchang Zeng, Jun Chen, Jun Kuang, Jin Zhang and Ying Wang, Influence of silane on corrosion resistance of magnesium alloy AZ31 with thermally sprayed aluminum coatings, Rare Metals, 2010, 29(2): 193.

Xue W.B., Deng Z.W., Chen R.Y., Zhang T.H., and Ma H., Microstructure and properties of ceramic coatings produced on 2024 aluminum alloy by microarc oxidation, J. Mater. Sci., 2001, 36(11): 2615.

Sundararajan G., and Krishna L.R., Mechanisms underlying the formation of thick alumina coatings through the MAO coating technology, Surf. Coat. Technol., 2003, 167(2–3): 269.

Jing Chen, Zexin Wang and Sheng Lu, Effects of electric parameters on microstructure and properties of MAO coating fabricated on ZK60 Mg alloy in dual electrolyte, Rare Metals, 2012, 31(2): 172.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, G., Zhao, J. Surface modification of die casting mold steel by a composite technique of hot-dipping and plasma electrolytic oxidation. Rare Metals 31, 362–367 (2012). https://doi.org/10.1007/s12598-012-0521-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-012-0521-8