Abstract

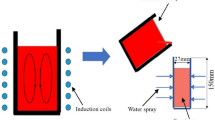

Semi-solid AlSi7Mg alloy slurry was prepared by low superheat pouring and weak traveling-wave electromagnetic stirring. The effects of pouring temperature and stirring power on the microstructure of AlSi7Mg alloy slurry were studied. The results show that the semi-solid AlSi7Mg alloy slurry of 5 kg can be prepared. This new technology can save energy and make the pouring process convenient. When the pouring temperature is decreased at a stirring power of 0.41 kW, the shape of primary α-Al grains gradually changes from dendritic-like to spherical. When the alloy melt is poured at the temperature (630°C) with a certain superheat, the pouring process becomes easier, and the spherical microstructure of AlSi7Mg alloy slurry can be prepared by the weak traveling-wave electromagnetic stirring. When the pouring temperature is 630°C, increasing the stirring power appropriately can result in better spherical primary α-Al grains, but if the stirring power is increased to a certain value (1.72 kW), the shape of primary α-Al grains does not obviously improve when the stirring power is continually increased.

Similar content being viewed by others

References

Flemings M.C., Behavior of metal alloys in the semi-solid state, Metall. Trans. A, 1991, 22(5): 957.

Flemings M.C., Riek R.G., and Young K.P., Rheocasting, Mater. Sci. Eng., 1976, 25: 103.

Mao W.M., Semi-solid Metal Forming Technology, China Machine Press, Beijing, 2004: 25.

Xie S.S. and Huang S.H., The Technology and Application of Semi-solid Metal Processing, Metallurgical Industry Press, Beijing, 1999: 34.

Zhu M.F. and Su H.Q., The present study status of semi-solid casting techniques, Spec. Cast. Nonferrous Alloys, 1996, (2): 29.

Midson S.P., The commercial status of semi-solid casting in the USA, [in] Proceedings of the 4th International Conference on Semi-solid Processing of Alloys and Composites, Sheffield, England, 1996: 251.

Young K.P., Kyonka C.P., and Courtoris J.A., Fine Grained Metal Composition, US Patent, Appl. 4415347, 1983.

Dobatkin V.I. and Eskin G.I., Ingots of aluminum alloys with nondendritic structure produced by ultrasonic treatment for deformation in the semi-solid state, [in] Proceedings of the 4th International Conference on Semi-solid Processing of Alloys and Composites, Sheffield, England, 1996: 193.

Cao H.B., Pan Y., and Zhang C., Compressing deforming behavior of semi-solid Al-Si alloy prepared by crystallization- controlling, Spec. Cast. Nonferrous Alloys, 2002, (3): 9.

Wang H., Stjone D.H., and Davidsion C.J., Controlled nucleation method for formation of semisolid feed stock, [in] Proceedings of the 8th International Conference on Semi-solid Progress of Alloys and Composites, Limassol, Cyprus, 2004: 269.

Liu D. and Cui J.Z., New technique of nonstirring solid slurry making and liquidus casting, Foundry Technol., 1998, (6): 44.

Mao W.M., Zhao A.M., and Cui C.L., The Preparing Method and Apparatus of the Spherical Primary Grain Semi-Solid Slurry or Continuous Slurry, Chinese Patent, Appl. 00109540, 2000.

Mao W.M., Zhao A.M., and Cui C.L., The Direct Preparing Method and Apparatus of the Spherical Primary Grain Semi-Solid Slurry or Continuous Slurry, Chinese Patent, Appl. 02104349, 2002.

Liu Z., Mao W.M., and Zhao Z.D., Research on semi-solid slurry of a hypoeutectic Al-Si alloy prepared by low superheat pouring and weak electromagnetic stirring, Rare Met., 2006, 25(2): 177.

Mao W.M., Bai Y.L., and Lin H., Effect of pouring height on the solidified microstructure of AlSi7Mg alloy, J. Univ. Sci. Technol. Beijing, 2006, 13(4): 324.

Mao W.M., Bai Y.L., and Tang G.X., Preparation for semi-solid aluminum alloy slurry under weak electromagnetic stirring condition, J. Mater. Sci. Technol., 2006, 22(4): 447.

Gao S.F., Mao W.M., and Bai Y.L., Li Q., Filling ability of semi-solid A356 alloy in rheo-casting and microstructure distribution, Spec. Cast. Nonferrous Alloys, 2005, 25(10): 598.

Pan Y., Zhang C.Y., Yuan H.Y., and Sun G.X., Effect of metal flow at initial solidification on granular primary crystal formation in semi-solid alloy, Acta Metall. Sin., 2001, 37(10): 1035.

Mao W.M., Zhao A.M., and Cui C.L., The formation mechanism of non-dendritic primary α-Al phases in semi-solid AlSi7Mg alloy, Acta Metall. Sin., 1999, 35(9): 971.

Mao W.M., Zhen Z.S., and Chen H.T., Microstructure of semi-solid AZ91D alloy solidified during electromagnetic stirring, Chin. J. Mater. Res., 2005, 19(3): 303.

Yurko J.A., Martinez R.A., and Flemings M.C., Development of the semi-solid rheocasting (SSR) process, [in] Proceedings of the 7th International Conference on Semi-solid Processing of Alloys and Composites, Tsukuba, Japan, 2002: 659.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, S., Mao, W. Preparation of semi-solid AlSi7Mg alloy slurry with big capability. Rare Metals 29, 642–645 (2010). https://doi.org/10.1007/s12598-010-0185-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-010-0185-1