Abstract

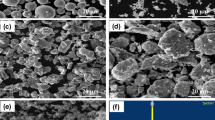

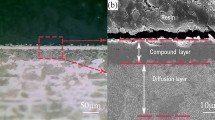

A composite layer was prepared on the surface of Ti-6Al-4V alloy by nitriding-sulfurizing composite treatment, and its microstructure and phase structure were examined by scanning electron microscopy (SEM) and X-ray diffraction (XRD), respectively. The tribological performance was measured to investigate its dependence on the nitriding-sulfurizing composite treatment process. The results indicated that the composite layer was mainly comprised of Ti2N, TiN, and TiS2. It was found that the composite layer exhibited superior tribological properties under dry friction and absolute sliding conditions due to the formation of sulfides with self-lubricating function.

Similar content being viewed by others

References

Zhecheva A., Sha W., Malinov S., and Long A., Enhancing the microstructure and properties of titanium alloys through nitriding and other surface engineering methods, Surf. Coat. Technol., 2005, 200(7): 2192.

Xu B. and Zhu S., Theory and Technique of Surface Engineering, International Industry Press, Beijing, 1999: 41.

PalDey S. and Deevi S.C., Single layer and multilayer wear resistant coatings of (Ti, Al) N: a review, Mater. Sci. Eng. A, 2003, 342(1–2): 58.

Shtansky D.V., Sheveiko A.N., Petrzhik M.I., Kiryukhantsev-Korneev F.V., Levashov E.A., Leyland A., Yerokhin A.L., and Matthews A., Hard tribological Ti-B-N, Ti-Cr-B-N, Ti-Si-B-N and Ti-Al-Si-B-N coatings, Surf. Coat. Technol., 2005, 200(1–4): 208.

Kim S.K., Ahn Y.H., and Kim K.H., MoS2-Ti composite coatings on tool steel by d.c. magnetron sputtering, Surf. Coat. Technol., 2003, 169–170(2): 428.

Steinmann M., Müller A., and Meerkamm H., A new type of tribological coating for machine elements based on carbon, molybdenum disulphide and titanium diboride, Tribol. Int., 2004, 37(11–12): 879.

Wang G. and Wang W., Chemical Heat Treatment of Steel, Chinese Railway Press, Beijing, 1982: 328.

Ivanovskaya V.V. and Seifert G., Tubular structures of titanium disulfide TiS2, Solid State Commun., 2004, 130(3–4): 175.

Li D., Qin X.Y., and Gu Y.J., The effects of bismuth intercalation on structure and thermal conductivity of TiS2, Mater. Res. Bull., 2006, 41(2): 282.

Bowden F.B. and Tabor D., The Friction and Lubrication of Solids, Oxford University Press, London, 1964.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Xing, Y., Wang, H. et al. Effect of nitriding-sulfurizing composite treatment on the tribological behavior of titanium alloys. Rare Metals 29, 604–607 (2010). https://doi.org/10.1007/s12598-010-0178-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-010-0178-0