Abstract

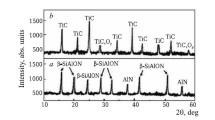

In situ formed low density O′-sialon-based multiphase ceramics were prepared by liquid-phase sintering method at 1400°C with Si3N4, SiO2 and Al2O3 as raw materials. Crystalline phases were identified by X-ray diffraction (XRD). The quantitative phase analysis was finished by matrix-flushing method and the substitution parameter x value of O′-sialon was estimated. The effects of sintering additives on the phase composition of the material were studied. The results show that, when using Y2O3 alone, Al6Si2O13 phase can be formed in the material, but when using Y2O3 and MgO, MgAl2O4 phase can be preferentially formed and the Al6Si2O13 is not observed. The mechanical properties of the material were measured and the relationships between microstructure and mechanical properties were discussed. The sample with Y2O3 and MgO sintering additives, using fused quartz alone as SiO2 source, displays a combination of high bending strength (163 MPa) and good fracture toughness (3.11 MPa·m1/2). Bending strength and fracture toughness of the samples increase with the increase of the content and aspect ratio of elongated grains and decrease with the increase of the porosity.

Similar content being viewed by others

References

Du D.M., Zhao S.K., Li H.P., Gao L., and Yang H.T., The pressureless sintering progress of silicon nitride ceramics, Shandong Ceram. (in Chinese), 2003, 26(4): 32.

Oyama Y. and Kamigaito O., Solid solubility of some oxides in Si3N4, J. Appl. Phys., 1971, 10(11): 1637.

Jack K.H. and Wilson W.I., Ceramics based on the Si-Al-O-N and related systems, Nat. Phys. Sci., 1972, 238(80): 28.

Ekstrom T. and Nygren M., Sialon Ceramics, J. Am. Ceram. Soc., 1992, 75(2): 259.

Izhevskiy V.A., Genova L.A., Bressiani J.C., and Aldinger F Progress in sialon ceramics, J. Eur. Ceram. Soc., 2000, 20(13): 2275.

Hou X.M. and Chou K.C., Oxidation behavior of SiAlON materials, J. Univ. Sci. Technol. Beijing (in Chinese), 2007, 29(11): 1114.

Shimada S., Tanaka M., Kiyono H., and MacKenzie K.J.D., Microstructure and properties of various fluorine-containing SiAlON ceramics synthesized by HIPing, J. Eur. Ceram. Soc., 2001, 21(16): 2811.

Ghosh G., Vaynman S., and Fine M.E., Microstructure of a sialon composite prepared by hot pressing and reactive sintering of β-Si3N4 coated with amorphous Al2O3, Ceram. Int., 1999, 25(7): 649.

Zhang H.J., Li W.C., and Zhong X.C., Mechanical properties and toughening mechanism of O′-Sialon-ZrO2-SiC composites, China Ceram. (in Chinese), 2002, 38(2): 4.

Jiang T., Xue X.X., Duan P.N., and Du G., Fabrication and properties of TiN/O′-sialon electroconductive composites, Acta. Metall. Sin. (in Chinese), 2007, 43(2): 131.

Barris G.C., Krouse D., and Hatchwll C., Densification of reaction bonded O-sialon: A graphical experimental approach for optimising process parameters, J. Mater. Sci., 2001, 36(14): 3373.

Duan R.G., Roebben G., Vleugels J., and Biest O.V., Optimization of microstructure and properties of in situ formed β-O-sialon-TiN composite, Mater. Sci. Eng. A, 2006, 427(1–2): 195.

Asada S., Ueki M., and Sugiyama M., O′-β-sialon ceramics, J. Mater. Sci., 1993, 28(14): 3789.

Lee B.T., Jeong H.G., and Hiraga K., Microstructures and fracture characteristic of Si3N4-O′-sialon composites using waste-Si-sludge, Mater. Trans., 2002, 43(1): 19.

Chung F.H., Quantitative interpretation of X-ray diffraction patterns of mixtures. I. Matrix-flushing method for quantitative multicomponent analysis, J. Appl. Crystallogr., 1974, 7(6): 519.

Zhou F. and He T.M., A Method to Determine the True Density of Ceramic Powders, Chinese Patent, Appl. 200510119035.8, 2005.

Chen Z.Y., Chemical Thermodynamics of Refractories (in Chinese), Metallurgical Industry Press, Beijing, 2005: 653.

Cai S., Meng J.H., Chen Y.R., Yang Z.F., and Yuan Q.M., The effects of rod-like mullite grain growth on mechanical properties of mullite matrix ceramics, Bull. Chin. Ceram. Soc. (in Chinese), 1999, 18(4): 10.

Heinrich J., Backer E., and Bohmer M., Hot isostatic pressing of Si3N powder compacts and reaction-bonded Si3N4, J. Am. Ceram. Soc., 1988, 71(1): 28.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, X., Liang, H., Li, X. et al. In situ synthesis and phase analysis of low density O′-sialon-based multiphase ceramics. Rare Metals 29, 214–219 (2010). https://doi.org/10.1007/s12598-010-0037-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-010-0037-z