Abstract

Nowadays, a popular term related to production inventory optimization for the greening effect and other policies is carbon emissions tax. Present paper deals with the application of queuing in supply chain management where demand is stochastic and involves carbon emissions and the learning effect. In the final, we have minimized the total inventory cost under queuing application for the supply chain management, where the learning effect follows simultaneous ordering cost, while demand is probabilistic. Numerical examples have been verified for the model, and sensitivity analysis of inventory parameters has been taken for good utilizations in various industrial scenarios.

Similar content being viewed by others

References

Fox, M.S., Barbuceanu, M., Teigen, R.: Agent-oriented supply-chain management. In: Information-Based Manufacturing, pp. 81–104. Springer, Boston, MA (2001)

Wright, T.P.: Factors affecting the cost of airplanes. J. Aeronaut. Sci. 3(4), 122–128 (1936)

Jayaswal, M., Sangal, I.S.H.A., Mittal, M., Malik, S.: Effects of learning on retailer ordering policy for imperfect quality items with trade credit financing. Uncertain Supply Chain Manag. 7(1), 49–62 (2019)

Harris, F.: Operations and Cost (Factory Management Series), pp. 48–52. AW Shaw Co., Chicago (1915)

Simon, H.A.: On the application of servomechanism theory in the study of production control. Econom. J. Economet. Soc. 20, 247–268 (1952)

Silver, E.A.: Operations research in inventory management: a review and critique. Oper. Res. 29(4), 628–645 (1981)

Parlar, M.: Continuous-review inventory problem with random supply interruptions. Eur. J. Oper. Res. 99(2), 366–385 (1997)

Ha, A.Y.: Stock-rationing policy for a make-to-stock production system with two priority classes and backordering. Naval Res. Logist. (NRL) 44(5), 457–472 (1997)

Isotupa, K.S.: An (s, Q) Markovian inventory system with lost sales and two demand classes. Math. Comput. Model. 43(7–8), 687–694 (2006)

Alimardani, M., Jolai, F., Rafiei, H.: Bi-product inventory planning in a three-echelon supply chain with backordering, poisson demand, and limited warehouse space. J. Ind. Eng. Int. 9(1), 1–13 (2013)

Seyedhoseini, S.M., Rashid, R., Kamalpour, I., Zangeneh, E.: Application of queuing theory in inventory systems with substitution flexibility. J. Ind. Eng. Int. 11(1), 37–44 (2015)

Wang, X.J., Choi, S.H.: Impacts of carbon emissions reduction mechanisms on uncertain make-to-order manufacturing. Int. J. Prod. Res. 54(11), 3311–3328 (2016)

Paul, A., Pervin, M., Roy, S., Maculan, N., Weber, G.: A green inventory model with the effect of carbon taxation. Ann. Oper. Res. 309(1), 233–248 (2022)

Rahaman, M., Abdulaal, R.M., Bafail, O.A., Das, M., Alam, S., Mondal, S.P.: An insight into the impacts of memory, selling price and displayed stock on a retailer’s decision in an inventory management problem. Fractal Fract. 6(9), 531 (2022)

Rahaman, M., Mondal, S.P., Alam, S., De, S.K., Ahmadian, A.: Study of a fuzzy production inventory model with deterioration under Marxian principle. Int. J. Fuzzy Syst. 24(4), 2092–2106 (2022)

Rahaman, M., Mondal, S.P., Chatterjee, B., Alam, S., Shaikh, A.A.: Generalisation of classical fuzzy economic order quantity model based on memory dependency via fuzzy fractional differential equation approach. J. Uncertain Syst. 15(01), 2250003 (2022)

Rahaman, M., Mondal, S.P., Alam, S., De, S.K.: A study of a lock fuzzy EPQ model with deterioration and stock and unit selling price-dependent demand using preservation technology. Soft. Comput. 26(6), 2721–2740 (2022)

Rahaman, M., Mondal, S. P., Chatterjee, B., & Alam, S.: Application of fractional calculus on the crisp and uncertain inventory control problem. In: Handbook of Research on Advances and Applications of Fuzzy Sets and Logic, pp. 120–148. IGI Global (2022)

Rahaman, M., Mondal, S. P., El Allaoui, A., Alam, S., Ahmadian, A., Salahshour, S.: Solution strategy for fuzzy fractional order linear homogeneous differential equation by Caputo-H differentiability and its application in fuzzy EOQ model. Adv. Fuzzy Integr. Differ. Equ. 412(1), 143–157 (2022)

Zhang, Y., Yue, D., Sun, L., Zuo, J.: Analysis of the queueing-inventory system with impatient customers and mixed sales. Discret. Dyn. Nat. Soc. 2022, 2333965 (2022)

Alamri, O.A., Jayaswal, M.K., Khan, F.A., Mittal, M.: An EOQ model with carbon emissions and inflation for deteriorating imperfect quality items under learning effect. Sustainability 14(3), 1365 (2022)

Shajin, D., Krishnamoorthy, A., Melikov, A.Z., Sztrik, J.: Multi-server queuing production inventory system with emergency replenishment. Mathematics 10(20), 3839 (2022)

Ghosh, A., Dey, M., Mondal, S.P., Shaikh, A., Sarkar, A., Chatterjee, B.: Selection of best e-rickshaw-a green energy game changer: an application of AHP and TOPSIS method. J. Intell. Fuzzy Syst. 40(6), 11217–11230 (2021)

Haque, T.S., Chakraborty, A., Mondal, S.P., Alam, S.: A novel logarithmic operational law and aggregation operators for trapezoidal neutrosophic number with MCGDM skill to determine most harmful virus. Appl. Intell. 52, 1–20 (2022)

Chakraborty, A., Mondal, S.P., Alam, S., Pamucar, D., Marinkovic, D.: A new idea to evaluate networking problem and MCGDM problem in parametric interval valued pythagorean arena. Discret. Dyn. Nat. Soc. 2022, 7369045 (2022)

Gazi, K.H., Mondal, S.P., Chatterjee, B., Ghorui, N., Ghosh, A., De, D.: A new synergistic strategy for ranking restaurant locations: a decision-making approach based on the hexagonal fuzzy numbers. RAIRO-Oper. Res. 57(2), 571–608 (2023)

Ghorui, N., Mondal, S.P., Chatterjee, B., Ghosh, A., Pal, A., De, D., Giri, B.C.: Selection of cloud service providers using MCDM methodology under intuitionistic fuzzy uncertainty. Soft. Comput. 27(5), 2403–2423 (2023)

Alzahrani, F.A., Ghorui, N., Gazi, K.H., Giri, B.C., Ghosh, A., Mondal, S.P.: Optimal site selection for women university using neutrosophic multi-criteria decision-making approach. Buildings 13(1), 152 (2023)

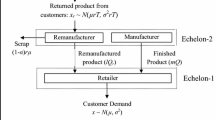

Pandey, J.D., Sharma, G.: A supply chain inventory model with some realistic situations. Int. J. Adv. Res. Eng. Technol. (IJARET) 13(8), 6–17 (2022)

Jayaswal, M.K., Mittal, M., Sangal, I.: Effect of credit financing on the learning model of perishable items in the preserving environment. In: Decision Making in Inventory Management, pp. 49–60. Springer, Singapore (2021)

Schwarz, M., Sauer, C., Daduna, H., Kulik, R., Szekli, R.: M/M/1 queueing systems with inventory. Queueing Syst. 54(1), 55–78 (2006)

Bhaskar, V., Lallement, P.: Modelling a supply chain using a network of queues. Appl. Math. Model. 34(8), 2074–2088 (2010)

Mahapatra, N.K., Bera, U.K., Maiti, M.: A production inventory model with shortages, fuzzy preparation time and variable production and demand. Am. J. Oper. Res. 2(2), 183–192 (2012)

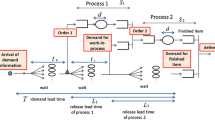

Rashid, R., Hoseini, S.F., Gholamian, M.R., Feizabadi, M.: Application of queuing theory in production-inventory optimisation. J. Ind. Eng. Int. 11(4), 485–494 (2015)

Pandey, D.K.: An attempt to understand the queueing -inventory system and the consideration of M/M/1/1 queueing-inventory model with retrial of unsatisfied customers. J. Adv. Sch. Res. Allied Educ. 16(5), 335 (2019)

Logeswari, A., Kavitha, M.: M/M/1 queueing model by using inventory theory. Malaya J. Mat. S, 3803–3806 (2020)

Liu, Y., Dehghani, E., Jabalameli, M.S., Diabat, A., Lu, C.C.: A coordinated location-inventory problem with supply disruptions: a two-phase queuing theory–optimization model approach. Comput. Ind. Eng. 142, 106326 (2020)

Aghsami, A., Samimi, Y., Aghaei, A.: A novel Markovian queueing-inventory model with imperfect production and inspection processes: a hospital case study. Comput. Ind. Eng. 162, 107772 (2021)

Ahmadini, A.A.H., Modibbo, U.M., Shaikh, A.A., Ali, I.: Multi-objective optimization modelling of sustainable green supply chain in inventory and production management. Alex. Eng. J. 60(6), 5129–5146 (2021)

Acknowledgements

The authors would like to thank the editor and the anonymous referees for their helpful remarks and recommendations in enhancing the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pandey, J.D., Sharma, G. A production supply chain inventory model with queuing application and carbon emissions under learning effect. OPSEARCH (2023). https://doi.org/10.1007/s12597-023-00710-8

Accepted:

Published:

DOI: https://doi.org/10.1007/s12597-023-00710-8