Abstract

The Reusable Flight Experiment (ReFEx) is an experimental vehicle currently in development by the German Aerospace Center (DLR), which simulates the reentry of a winged reusable booster stage. The topic covered in this paper is the aerodynamic design through the Mach number range from 5.0 to 0.8, including the transonic regime, by CFD simulations using the DLR TAU-Code. For steering and lift generation, the vehicle is equipped with multiple aerodynamic surfaces: canards, wings and a vertical fin. A VSB30 was chosen as the carrier rocket, leading to numerous limiting conditions that had to be fulfilled. The resulting tradeoffs are discussed. Also the process to achieve a configuration that meets all needs regarding stability during ascent and descent, controllability and energy management to autonomously follow a desired trajectory is explained. Since this vehicle is under development, the presented geometry is not necessarily the final shape. However, the completed design iterations strongly indicate that only details will differ between the presented state to the final and flyable ReFEx, scheduled to fly in 2022.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Access to space is no longer a privilege to few industrialized countries, but is part of the globalized world’s technologies at a growing number of countries’ disposal. This technological advancement comes with an increasing number of competing governmental agencies and also companies in the private sector. Therefore, it has become important to not only build reliable but also cost-efficient launch vehicles. One attempt to reduce the cost of launching payload into orbit is to use parts of the carrier rocket multiple times, demonstrated by SpaceX’s Falcon rocket. They reuse the rocket’s booster stage after landing it vertically. An alternative take on the landing procedure is a horizontal, airplane-like, approach. This is the basic idea of ReFEx, a flight experiment to prove this concept.

Reusable spacecraft which land horizontally include the Russian Buran and the American Space Shuttle. However, they are designed to withstand a high-speed reentry from an orbital trajectory, whereas ReFEx is only exposed to Mach numbers up to 5.0 for a relatively short time period. Also, the objective of a reusable booster stage is to transport fuel, not astronauts or satellites. A vehicle with a rather similar purpose to ReFEx is the Russian Baikal Booster stage, which is under development. It is a reusable booster stage, so most of its requirements are the same as ReFEx. Aerodynamically, the main difference is the Baikal Booster’s rotatable wing, which, in conjunction with a jet engine, allows the Baikal Booster to cover a large distance over ground during the return flight. This way it can return to its launch point even if the trajectory is rather flat-angled.

Other projects in this field include the Hopper project of the ESA which resulted in the 7-m-long Phoenix vehicle. It has short double delta wings and airplane-like landing gear. But the project was stopped after one successful drop test from a helicopter from around 2 km height in 2004 [1]. This experiment covered the landing phase. Another flown experimental vehicle is the Hypersonic Flight Experiment (HEX) from the Indian Reusable Launch Vehicle Technology Demonstrator Programme (RLV-TD) that was propelled to a height of 65 km at Ma = 5 in 2016. Reportedly, this 1-m diameter vehicle flew controlled for 770 s and ended its flight with a planned splashdown and was not recovered [2]. The midterm goal of the HEX vehicle, however, is to serve as a scramjet testing platform and therefore to withstand higher heat loads. Nevertheless, criteria such as navigation and control are quite comparable to ReFEx.

ReFEx is the first flight experiment in the current DLR roadmap towards hypersonic transport vehicles. With this flight experiment, a good portion of the necessary experience and basic knowledge will be gained to build a reusable booster stage. The long-term goal is hypersonic travel around the world.

1.1 Mission objectives

The flight of ReFEx consists of three phases: the ascending, the experimental and the landing phase. First, the ascent takes place. ReFEx is propelled by a VSB30 carrier system to a height of about 100 km and a Mach number of approx. 5.0. After separating all carrier-related parts, the experimental phase begins. In this phase, ReFEx is tasked to autonomously follow a predefined trajectory to reach the target destination, an ellipsoid about 10 km above ground, at a subsonic speed. Reaching this target marks the start of the landing phase. Since ReFEx is not equipped with landing gear, the current plan is to perform a flare to touch ground with least possible damage to the vehicle.

The main focus of the aerodynamic investigations lies on the experimental phase. It starts outside of any notable atmospheric influence. A cold gas system will orientate ReFEx into an aerodynamically stable state to enter the aerodynamically dominated part of the reentry without any difficulty. The initial deceleration will be done at high angles of attack to keep the structural and aerothermal loads within an acceptable range. Later, the angle of attack will be decreased to fly at angles close to a state of the maximum lift-to-drag ratio, which is around α = 10°. During the entire experimental phase, the energy management is of great importance to reach the destination at the desired speed. To achieve this, a corridor of flyable pitch angles and bank angles around the one preset to maintain the trajectory has to be made available. A more detailed description of the mission can be found in the overview paper [3].

A successfully completed experimental phase as described above will fulfill the following mission objectives:

-

Precise orientation of ReFEx with an reaction control system (RCS).

-

Steering throughout a the range of Mach numbers from 0.8 to 5.

-

Energy management system to reach the target at the desired speed.

Additionally, if the landing segment is carried out successfully, several other capabilities of ReFEx will be demonstrated. These include stability and maneuverability in the low Mach number regime as well as an accurate altitude measurement. Last but not least, collecting the vehicle, retrieving the stored data and examining the landing damage are important steps to gain additional knowledge for other upcoming flight experiments.

1.2 Configuration overview

The configuration originates from an older study [4] with the shared goal of designing a reusable booster stage but containing different constraints. This low-wing configuration was laid out with two canards and two angled fins. It also has a body flap, which was not used for ReFEx. Only longitudinal investigations concerning stability were conducted (see Fig. 1, left). Stability investigations of the old configuration revealed that it was not statically directionally stable. Still, this was a good starting point to design ReFEx.

The design process was dominated by several side conditions, most prominently by the launch vehicle being a VSB30 system. It constrained dimensions, mass and aerodynamic properties of the flight experiment for the ascent phase which means:

-

ReFEx had to be symmetrical because the VS30 is a ballistic missile.

-

Mass and dimensions needed to fit a certain window.

-

Side wind forces during ascent had to be sufficiently small.

To avoid or fix most of the ascent difficulties, a fairing will be used. It will cover the asymmetrical wings and thus lower the side forces. Since the wings were too large to fit under a fairing, foldable wings were chosen to fix this problem. This allowed the fairing to be sufficiently slender, as the stability analysis in Chapter 3 shows. The space inside the fairing that was required by the folded wings led to switching from two angled fins to a single vertical fin. Furthermore, a downscaling from a 0.43 to a 0.355 m diameter was done because of the carrier’s capabilities, resulting in a total length of 2.72 m. The configuration after these changes is depicted in Fig. 1, right. The separation of the fairing and the upper stage rocket takes place in an atmosphere-free environment. Therefore, small forces of prestressed springs are sufficient to separate the parts.

Preliminary investigations on the heat loads have been conducted [5] that suggest that most of the fuselage structure can be built of aluminum. Because of ReFEx’s aerodynamic capabilities to fly at high angles of attack even for more exposed parts such as the aerodynamic surfaces and the fuselage tip, the aerothermal loads are low enough that it is sufficient to use titanium which means expensive ceramic components can be avoided.

2 Analysis methods

2.1 Flow simulations

All flow simulations were carried out with the DLR TAU-Code (TAU). It is a cell-centered finite volume solver, iterating towards the solution of the compressible Navier–Stokes equations with a turbulence model as closing condition. For use cases in which viscous effects can be neglected, the simplified Euler equations (Navier–Stokes equations without viscous terms) can be used, yielding faster results. The flux information is transported via second-order AUSM upwind scheme. Validation of TAU over a wide range of geometries and flow conditions has been conducted in several studies [6,7,8].

The discretization was done with Centaur [9]. For the Euler simulations, unstructured tetrahedron meshes were used. The accepted convergent cell count is around 4.1 million. The Navier–Stokes simulation meshes consist of an additional structured boundary layer, leading to a hybrid mesh. The cell count for these meshes is about 11 million.

The current aerodynamic database for ReFEx consists of two types of simulations. Simulations using the Navier–Stokes equations with a Spalart–Allmaras one-equation turbulence model were carried out for Mach numbers smaller than 2. For higher Mach numbers, viscous effects on the pitching moment coefficient were negligible, therefore Euler equations were used. Because the viscous terms are neglected for the latter simulations, they are independent of the surrounding atmosphere and therefore valid for any continuum flow condition at that Mach number. However, to determine the vehicle’s drag accurately viscous effects for these simulations were included post-simulation with a semi-empiric viscous correction term based on flat plate friction. The corrected drag coefficients were used for trajectory assessment. The simulations including viscous terms are atmosphere sensitive. For the preliminary aerodynamic design, only static simulations were carried out.

2.2 Stability criteria

The design of ReFEx was focused around aerodynamic static stability. The used coordinate system is from the DIN 9300 [10], a righthanded coordinate system with the x-axis pointing forward and the z-axis downward (also depicted in Fig. 2). A flight condition is stable if small disturbances are diminished over time without steering actively. For the longitudinal movement, this is described by the pitching moment coefficient derivative of the angle of attack Cmα. Positive values equal an unstable condition, because increasing the angle of attack increases the pitching moment. Therefore, the vehicle would progressively pitch faster. Negative values of Cmα equal a stable condition, since increasing angles of attack lower the pitching moment. The decrease of pitching moment counteracts the disturbance and therefore diminishes it.

The lateral movement contains two major derivatives of interest: Cnβ which is the yawing moment coefficient derivative over the sideslip angle β and Clβ the respective rolling moment coefficient derivative. For Cnβ, the definition is straightforward and analog but sign reversed to the pitching movement. For positive values, the vehicle is stable. Negative values refer to an unstable condition. The situation for Clβ is not so easy to answer. Both positive and negative values lead to a rolling motion. A first assessment might lead to the conclusion, that the rolling movement can be seen as stable if the vehicle rolls in a way that it turns inwards, counteracting the side slip angle. This circumstance refers to positive values of Clβ. However, larger absolute values of both signs can quickly lead to uncontrollable roll rates. Without detailed analysis, it can only be said that small absolute values of Clβ are positive for the vehicle’s controllability.

In the first aerodynamic design iteration, entering statically unstable pitching or directional conditions during descent was viewed as the limiting factor. This was done to lower the necessary abilities of the control system to minimize development cost. Hence, the range of flyable pitch angles is the span of stable trim point alphas from minimum to maximum canard deflection. Two of the geometry options that passed through these static stability criteria were investigated in more detail. Their aerodynamic properties are described in Chapter 4.

3 Stability analysis for the ascent phase

During the ascent phase, ReFEx is covered with a fairing and equipped with a dummy fin to ensure symmetry. This is necessary because the carrying rocket is a ballistic rocket, unable to steer actively. The corresponding geometry with the fairing for the ascent is shown in Fig. 2.

The goal of the ascent investigation is to ensure flight stability. Static stability is achieved if the position of the aerodynamic neutral point is rearwards from the center of gravity. In the case of a rocket for which all relevant moments and forces are zero for α = 0° and the moment reference center is at x = 0, the x-position of the aerodynamic neutral point xNP is calculated using

here Cm is the pitching moment coefficient and Cz is the force coefficient along the z-axis. Both coefficients need to be taken from a small angle of attack inflow. To account for errors in the simulation and the geometry as well as eventually necessary minor changes to the vehicle, a margin called static margin (SM) is defined. It expresses the distance between aerodynamic neutral point and the center of gravity (xCG), normalized to the rocket’s diameter. Therefore, the unit it is measured in is caliber with the calculation formula being

Usually preliminary engineering design tools are used for this investigation, however due to their insufficient accuracy, additional analyses with the DLR TAU-code were conducted. For this case, there are two different planes with destabilizing surfaces in the vehicle. The first is in the canard plane, the other one is in the plane of the vertical tail and dummy fin. Generally, it would be sufficient to investigate the most unstable tilting movement of the rocket. In this case, both planes have significant destabilizing surfaces. In the canard plane, smaller destabilizing faces (the canards) are present, but located closer to the tip which lengthens their moment arm. The vertical tail plane has larger destabilizing faces, but they have a smaller moment arm. A tilting movement of both planes as well as a 45° angled tilt was investigated (overlaid axes in Fig. 2). The results are shown in Fig. 3.

The vehicle is scaled down to obtain a static margin of 1.4, which has been chosen as the safety margin. The fins of the propelling stages were already maxed out. Over the entire ascent trajectory, this critical value was not undercut for any of the investigated tilting movements. Also, the need to look at more than one tilt became obvious, since both the canard and the vertical tail plane have about the same minimum value, but at completely different Mach numbers. Similar investigations of previous configurations revealed that the lowest static margins appear for supersonic flight conditions. Therefore, only this region was analyzed during the preliminary design process. The movement of the center of gravity along the trajectory due to fuel consumption was taken into account.

Considering these findings, the investigated geometry is stable and can ascent via ballistic missile. Also the maximum size of the ReFEx’s aerodynamic surfaces is set by this analysis, since enlarging them would lower the static margin. Downsizing of the aerodynamic surfaces from the investigated size increases the stability of the ascent configuration and therefore is feasible with respect to ascent stability.

4 Investigated geometries during the aerodynamic design approach

In the following sections, the aerodynamic properties of the investigated configuration possibilities alongside a short evaluation are given starting with the reference from the first design iteration. The changes in aerodynamic behavior of the second iteration geometries are briefly discussed. All coefficients are calculated using the vehicle length of 2.72 m as reference length and the circular cross-section of 0.113 m2 as reference area.

For the design process, several Mach numbers were calculated. The main qualitative differences in aerodynamic properties are between the subsonic and supersonic regime. The subsonic characteristics are well represented by Ma = 0.8 and the supersonic properties by Ma = 4. An overview is therefore given by analyzing these Mach numbers.

4.1 First geometry iteration—reference geometry

The insufficient directional stability was initially tackled by increasing the fin size of ReFEx to the maximum in agreement with the stability investigation for the ascent phase. Also, the fuselage–wing connection was remodeled to reduce the aerodynamic drag (Fig. 4).

The new geometry, similar to the old one, has good longitudinal aerodynamic properties. In Fig. 5, left the pitching moment coefficient curve for two Mach numbers and two canard deflections is shown. The Mach 0.8 curves are representative of the subsonic regime, whereas the Mach 4 curves represent the supersonic regime. The steering capability of the canards (difference in Cm for different canard angles η) is almost constant for the Mach 4 regime over the entire angle of attack range, but shows a strong angle of attack dependency for subsonic Mach numbers. This leads to a wide stable and trimmable range for high Mach numbers and a more narrow range for subsonic velocities.

The lateral motion also yields promising results. In Fig. 5 right, the yawing moment coefficient derivative for different Mach numbers is shown. Positive values represent statically stable conditions. Even though the fin size was increased significantly, for a moment reference point of 60% vehicle length, directional stability could not be achieved for α > 5°. However, Ma < 1.5 is directionally stable for angles of attack around 10°. At these lower Mach numbers, the canards do not provide enough lift to reach high angles of attack. Therefore, not the entire angle of attack range was simulated.

Having the properties of this reference geometry, different attempts to enhance the directional and if possible also the longitudinal properties have been investigated. The design goal with respect to the lateral motion is static directional stability. Longitudinal wise, an increase of stable and trimmable angles of attack would be desired. The two most promising candidates are described in the following subsections.

4.2 Option 1—additional fin on the bottom side of the vehicle

One approach to fix the directional stability issue of the reference geometry is the addition of another rear fin on the bottom side of the vehicle to generate a large enough stabilizing moment whenever a sideslip angle occurs. To match the symmetric criteria for ascent, a fin the same size as the top fin was chosen (see Fig. 6). This configuration change was done along with several other smaller changes. These include a dihedral angle of 5° and canard base planes to avoid gaps while deflecting the canards.

These geometry changes only have small influence on the longitudinal properties in the high Mach number regime (Fig. 7, left). The impact on the tans- and subsonic regime is visible (Fig. 7, right). The overall characteristics are not changed, but a shift of the trimmable angle of attack towards greater values in the low-speed regime occurs.

At first glance, this behavior is non-intuitive, because an added fin on the bottom should lower the Cm value through its drag. But the effect of the flow being disturbed plays a greater role here: or subsonic velocities, less rearward lift is generated, increasing Cm as can be seen in Fig. 7, right. In the high-speed regime, the balance of these effects lies differently, resulting in only small changes.

However, the primary goal was to improve the directional stability. Cnβ with positive values representing statically stable flight conditions were determined (Fig. 8) and therefore the goal to reach directional stability is achieved.

There is a minimum value around α = 25°. This minimum was investigated with the conclusion that the upper fin acts counterintuitively. The coefficients of the fins are shown in Fig. 9, left. Contrary to the intuitive take, a rudder direction change occurs (sign change of blue curve). This not only leads to a stability minimum in Cnβ, but also to high values of the rolling cross-derivative Clβ. Large absolute values of this coefficient equal high roll rates induced by β (Fig. 9, right).

Unfortunately, the rolling movement was too unstable to control. To fix this problem, the size of the fins would have to be reduced. But this would lead to an overall reduction in directional stability, which has values close to zero already. To counter this, a forward shift of the center of gravity would be required, which in return reduces the trimmable angle of attack range. But a reduction of the angle of attack during the beginning of the reentry would lower the initial deceleration, hence increasing the loads on the vehicle. Summing up, this configuration does not fulfill the requirements.

4.3 Option 2—upside-down deceleration

A different take on how to deal with the aerodynamic difficulties over the wide Mach range is to perform a maneuver to maintain directional stability. The general idea is to optimize ReFEx for the scenario in which the start of the reentry is flown with a roll angle of 180° and later it is changed to 0°. This way, the fin should be able to provide directional stability in the high Mach number regime, while at lower Mach numbers the needed lower angles of attack are trimmable. The geometry for this case is depicted in Fig. 10. Aerodynamically, the main difference towards the reference geometry is the adjusted fin size and the forward shift of the center of gravity to 57% vehicle length.

From a system point of view, the shift of the center of gravity is problematic, as a lot of the structural mass is in the rear end of the vehicle. However, the lift of the wings is significantly decreased during the upside-down flight phase. Therefore, a 60% MRP would not yield an acceptable range of trimmable angles of attack. System wise, 57% MRP can be achieved, but is close to the maximum forward positioning without adding trim weight to the tip.

The concept of this option comes from the idea of adding the least possible additional complexity to the geometry but still somehow managing to achieve controllability during the descent. This concept adds additional difficulty only with respect to flight maneuvers, which ReFEx would need to be able to potentially carry out anyway. However, with this concept, the area on the trajectory in which the roll maneuver has to happen is limited.

The aerodynamic properties before and after the roll maneuver differ significantly. Therefore, they are analyzed separately. Figure 11, shows representative longitudinal and lateral properties in the Mach range from 6 down to 1.5. This Mach range is flown with a roll angle of 180°, leading to negative angles of attack in the body-fixed reference frame generating lift. To compare this option with the reference geometry, the angle of attack and the coefficients sign were changed. Also bear in mind that opposite signs of the canard deflection angles correspond.

The trimmable alpha range shifts upward, while the directional stability is enhanced. In comparison to the reference geometry, the size of the fin has been reduced to lower the sideslip-induced rolling moment. This change produces a directionally unstable region (high Mach numbers combined with low alpha), however this is unproblematic, because it is outside of the planned flight corridor.

For the lower velocities, the nominal vehicle orientation (roll angle of 0°) is investigated. The aerodynamic characteristics after the maneuver are depicted in Fig. 12. The longitudinal properties on the left side have not changed compared to the reference geometry. The directional stability is reduced by a bit, but still stable. This is the combined effect of the stabilizing forward shift of the center of gravity and the destabilizing fin size reduction.

One important design criteria was the rolling motion. The coefficient used to investigate this movement is the rolling moment induced by a sideslip angle, the rolling moment derivative Clβ. The comparison of this aspect of Option 1 and Option 2 is shown in Fig. 13 for Ma = 4. Around this flight Mach number, great lateral instabilities occurred with Option 1. The design goal is to achieve small absolute values which resemble small rolling rates and therefore an easily controllable condition. For this Mach number, absolute Clβ values could be reduced by one magnitude. This reduction occurs during the entire supersonic regime with its maximum effectiveness at Ma = 4.

The main problem of Option 1 is that the instabilities most likely induced by the rolling motion were enhanced significantly. Option 2 shows promising properties and therefore is the chosen geometry that will be used for further and more detailed analysis.

4.4 Aerodynamic properties of the chosen geometry

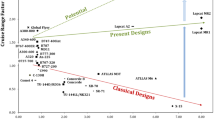

During the design process of ReFEx, several geometries were analyzed, leading to the decision to use Option 2 (Sect. 4.3). The main reason for this choice is that this version is the simplest investigated vehicle hardware wise to fulfill all mission requirements. Taking a closer look into its flight capabilities reveals a broad range of trimmable angles of attack over a wide Mach number range (see Fig. 14). These values were extrapolated from the currently available simulation results (currently for this geometry around 600).

There is a flyable corridor of the upside-down configuration down to low Mach numbers. However, it is very narrow at the end. The reason for this is the separated flow around the canards (see Fig. 15) due to the high effective angle of attack of the canards. Although this would not impose a stability problem, no steering is possible. To avoid this, a rolling maneuver takes place at around Mach 1.5.

This maneuver will have to start with an angle of attack between − 15° and − 25° and has to finish at around 8°. It cannot be a simple banking maneuver, since the angle of attack has to change. The maneuver rotation axis therefore has to be somewhere in between the aerodynamic x-axis and the vehicle x-axis. After the maneuver, at angles of attack around 8°, steering is possible because the effective angle of attack of the canards is low enough.

Flying belly-up at high Mach numbers ensures directional stability. However, the fin is generating a lot of drag and the wings produce less lift than in the nominal position. A visualization of these changes can be achieved with the lift-to-drag ratio, which is depicted in Fig. 16. The reentry part (Ma > 3) is flown with high angles of attack, therefore the L/D ratio is around 1. Timewise, the subsonic regime is a large part of the trajectory. It is planned to fly at the highest possible L/D ratio after performing the roll maneuver.

Further analysis of the flyable pitch angles will have to cover phenomena like the mentioned steering capability, the dynamic behavior and coupling of motions like the roll–yaw coupling of Option 1 (see Sect. 4.2). Since those effects have already been covered for some critical points, no negative influence is expected. The range might even be widened, if the dynamic derivatives damping is strong enough to allow an expansion of the flyable corridor into aerodynamically unstable territory.

5 Conclusion

The preliminary aerodynamic design of ReFEx was governed by the side conditions due to the carrier rocket. Most important were the overall size of ReFEx and the symmetry requirements for the ascent phase. After investigating several geometries to achieve aerodynamical stability over the entire envelope as well as a sufficiently large trimmable angle of attack range, a concept was found to cover all requirements. It is described in Sects. 4.3 and 4.4.

The basic concept is to start the reentry upside down, with a roll angle of 180°, and perform a roll maneuver at around Ma = 1.5 to a state with a roll angle of 0°. Before the roll maneuver, the downward pointing fin gives directional stability and the high-wing configuration generates little enough rearward lift to allow high angles of attack. After the maneuver, ReFEx is in its nominal orientation with a low-wing configuration. Now, more rearward lift is generated which allows trimming rather small angles of attack. This is important to ensure controllability through the canards, which have separated flow, and therefore loss of steering effect, at higher angles of attack. Also, the now upwards pointing fin generates sufficient stabilizing momentum for directional stability at the occurring low Mach numbers.

The main focus of the aerodynamic work for ReFEx lies in finalizing the geometry. The parts to be finalized are the canards and a flap, which will be included into the vertical fin. Their size will be determined through smaller datasets which determine whether their impact is sufficient. Also, the coupling of yawing and rolling of the flap needs to be investigated. After the geometry is finalized, extensive datasets need to be computed to lay out the flight range for the trajectory and the control systems. This also is an iterative process that already was part of the first aerodynamic iteration. The current state suggests no major unpleasant surprises. The final dataset includes further analysis including dynamic derivatives and is estimated to contain more than 12,000 simulated flight points.

Change history

16 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12567-021-00379-z

Abbreviations

- C:

-

Aerodynamic coefficient

- Ma:

-

Mach number

- d:

-

Diameter

- x, y, z :

-

Force in x-, y-, z-axes direction

- α :

-

Angle of attack

- β :

-

Sideslip angle

- CG:

-

Center of gravity

- NP:

-

Neutral point

- l, m, n :

-

Moment around x-, y-, z-axes

- p:

-

Pressure

- x, y, z :

-

Body-fixed x-,y-, z-axes

- CFD:

-

Computational fluid dynamics

- DLR:

-

German Aerospace Center

- MRP:

-

Moment reference point

- ReFEx:

-

Reusable flight experiment

- SM:

-

Static margin

- TAU:

-

Triangular adaptive upwind

Reference

Gockel, W., Kyr, P., Janovsky, R., Roenneke, A.: Reusable RLV demonstrator vehicles-phoenix flight test results and perspectives. Space Technol. 25(1), 1–14 (2005)

Yadav, S., Jayakumar, M., Nizin, A., Kesavabrahmaji, K., Mohan, N.S.: Final phase flight performance and touchdown time assessment of TDV in RLV-TD HEX-01 mission. J. Inst. Eng. (India) Ser. C 98(6), 679–688 (2017)

Rickmers, P.: ReFEx: Reusability flight experiment. A flight experiment to demonstrate controlled aerodynamic flight from hypersonic to subsonic velocities with a winged RLV. In: EUCASS 2017–644 (2017). Doi: 10.13009/EUCASS2017-644

Eggers, Th.: Aerodynamic Behaviour of a Liquid Fly-back Booster in Transonic Cruise Flight. AIAA Paper 2003–3422 (2003).

BAUER, W. et al.: DLR reusability flight experiment ReFEx. Acta Astronaut 168. Jg., S. 57–68 (2020)

Mack, A., Hannemann, V.: Validation of the unstructured DLR TAU-Code for hypersonic flows. AIAA Paper 2002–3111 (2002)

Schwamborn, D., Gerhold, T., Heinrich, R.: The DLR TAU-Code: recent applications in research and industry. In: Wesseling, P., Oñate, E., and Périaux, J (eds) Proceedings of the European conference on computational fluid dynamics. Delft University of Technology, Delft, The Netherlands (2006).

Gerhold, T., Galle, M., Friedrich, O., and Evans, J.: Calculation of complex three-dimensional configurations employing the DLR-TauCode. In: 35th Aerospace Sciences Meeting and Exhibit, AIAA Paper 1997–0167 (1997)

CentaurSoft: https://www.centaursoft.com/. Accessed Oct 2018

DIN 9300: Begriffe, Größen und Formelzeichen in der Flugmechanik (English title: DIN 9300: concepts, quantities and symbols for flight dynamics). Beuth, Berlin (1990)

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to a retrospective Open Access order.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Merrem, C., Wartemann, V. & Eggers, T. Preliminary aerodynamic design of a reusable booster flight experiment. CEAS Space J 12, 429–439 (2020). https://doi.org/10.1007/s12567-020-00313-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12567-020-00313-9