Abstract

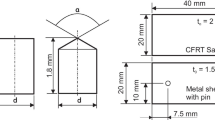

This study researches a novel advanced joining technique, utilizing metal additive manufacturing, named μPinning. μPins are small pin-like structures manufactured on a metal substrate and used to penetrate and be consolidated inside a fibre-reinforced polymer (FRP) laminate as through-the-thickness reinforcement during curing (Ucsnik et al. in Composite to composite joint with lightweight metal reinforcement for enhanced damage tolerance. ECCM16—16th European Conference on Composite Materials, Seville, Spain, 2014, Parkes et al. in Compos Struct 118:250–256, 2014). Prior studies have shown a significant increase in the load bearing capabilities of the joint [1, 2], as well as greater performance in dynamic and fatigue loads (Graham et al. in Compos Part A 64:11–24, 2014, Chang et al. in Compos Sci Technol 66(13):2163–2176, 2006, Ko et al. in Compos Struct 119:59–66, 2015]. The main objective of this research is to use numerical optimization tool to optimize the shape of a μPin, as studies have shown that the shape of the μPin exhibits a significant role in the mechanical response [1, 2, 5, 7]. After the numerical optimization, experimental testing was performed to validate the assumption of the importance of the μPin shape in the joint loading response. Finally, this study aims to lead to future research on the design of metal inserts in sandwich structures and struts for use in space applications.

Similar content being viewed by others

References

Ucsnik, S., Stelzer, S., Sehrschon, H., Sieglhuber, G.: Composite to composite joint with lightweight metal reinforcement for enhanced damage tolerance. In: ECCM16—16th European Conference on Composite Materials, Seville, Spain (2014)

Parkes, P.N., Butler, R., Meyer, J., de Oliveira, A.: Static strength of metal composite joints with penetrative reinforcement. Compos. Struct. 118, 250–256 (2014)

Mouritz, A.P.: Review of z-pinned composite laminates. Compos. Part A 38(12), 2383–2397 (2007)

Smith, F., Wylde, G.: COMELD—an innovation in composite to metal joining. Mater. Technol. 49(2), 26–27 (2005)

Graham, D.P., Rezai, A., Baker, D., Smith, P.A., Watts, J.F.: The development and scalability of a high strength, damage tolerant, hybrid joining scheme for composite–metal structures. Compos. Part A 64, 11–24 (2014)

Chang, P., Mouritz, A.P., Cox, B.N.: Properties and failure mechanisms of pinned composite lap joints in monotonic and cyclic tension. Compos. Sci. Technol. 66(13), 2163–2176 (2006)

Ko, M.G., Kweon, J.H., Choi, J.H.: Fatigue characteristics of jagged pin-reinforced composite single-lap joints in hygrothermal environments. Compos. Struct. 119, 59–66 (2014)

Heimbs, S., Nogueira, A.C., Hombergsmeier, E., May, M., Wolfrum, J.: Failure behaviour of composite T-joints with novel metallic arrow-pin reinforcement. Compos. Struct. 110, 16–28 (2013)

Satish Prakasha, K., Nancharaihb, T., Subba Raoc, V.V.: Additive manufacturing techniques in manufacturing—an overview. Mater. Today Proc. 5(2), 3873–3882 (2017). (Part 1, 2018)

Ngo, T.D., Kashani, A., Imbalzano, G., Nguyen, K.T.Q., Hui, D.: Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos. Part B 143, 172–196 (2018)

García-Cosío, M., Miguel González, J., Vermeulen, J., Rossmann, C., Kranz, J.: Additive manufacturing hot bonded inserts in sandwich structures. https://www.slideshare.net/JuanMiguelGonzalezHe1/additive-manufacturing-hot-bonded-inserts-in-sandwich-structures (2016). Accessed 02 Oct 2018

Yasaee, M., Bigg, L., Mohamed, G., Hallett, S.R.: Influence of Z-pin embedded length on the interlaminar traction response of multi-directional composite laminates. Mater. Des. 115, 26–36 (2017)

Toral Vazquez, J., Castanié, B., Barrau, J.J., Swiergiel, N.: Multi-level analysis of low-cost Z-pinned composite joints Part 1: single Z-pin behavior. Compos Part A 42(12), 2070–2081 (2011)

Bianchi, F., Zhang, X.: Predicting mode-II delamination suppression in z-pinned laminates (2012). Compos. Sci. Technol. 72(8), 924–932 (2012)

Pingkarawat, K., Mouritz, A.P.: Improving the mode I delamination fatigue resistance of composites using z-pins. Compos. Sci. Technol. 92, 70–76 (2013)

Ucsnik, S., Scheerer, M., Zaremba, S., Pahr, D.H.: Experimental investigation of a novel hybrid metal–composite joining technology. Compos. Part A 41(3), 369–374 (2009)

Stelzer, S., Ucsnik, S., Pinter, G.: Strength and damage tolerance of composite–composite joints with steel and titanium through the thickness reinforcements. Compos. Part A 88, 39–47 (2016)

MSC.Software: MSC Nastran 2012 Documentation, MSC Nastran 2012—design sensitivity and optimization user’s guide. pp. 361–365 (2012)

Acknowledgements

This research is funded and supervised on part by ESA (Grant no. 90k€), under the auspices of the ESA/NPI programme.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarantinos, N., Kostopoulos, V., Di Vita, G. et al. Micro-pins: the next step in composite–composite and metal–composite joining. CEAS Space J 11, 351–358 (2019). https://doi.org/10.1007/s12567-019-00251-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12567-019-00251-1