Abstract

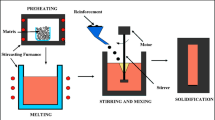

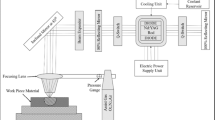

Laser machining is a technique capable of achieving extremely precise material cutting using appropriate parameters. The research proposes a new approach for producing biodegradable hybrid composites composed of Polylactic acid (PLA), bamboo particles (BP), and montmorillonite (MMT) clay using an innovative solvent-free stir-casting technique optimised for maximum efficiency. The primary objective is to evaluate the machinability of the resultant PLA/BP/clay hybrid polymer composite in-depth, emphasising important quality characteristics such as surface roughness, kerf angle, and material removal rate. The key machining parameters under consideration are laser power, scan speed, and gas pressure. This evaluation encompassed the utilisation of Analysis of Variance (ANOVA) to comprehend the extent of impact these process parameters have on the quality characteristics. Additionally, an interactive model was developed for forecasting and enhancing the quality parameters of laser cutting using Response Surface Methodology (RSM). The Particle Swarm Optimisation (PSO) algorithm was also employed to determine the optimal values of the design parameters for machining composites. The laser power has been precisely optimised to a value of 21.40 W. A constant setting of 3 mm/s for the scan speed and 3.04 bar of gas pressure enables accurate and controlled laser machining of the hybrid polymer composite.

Similar content being viewed by others

Availability of Data and Materials

Data sharing does not apply to this article as no new data were generated during the study.

References

Kamarudin, S. H., Mohd Basri, M. S., Rayung, M., Abu, F., Ahmad, S., Norizan, M. N., … Abdullah, L. C. (2022, September 1). A review on natural fiber reinforced polymer composites (NFRPC) for sustainable industrial applications. Polymers. MDPI. https://doi.org/10.3390/polym14173698

Mishra, T., Mandal, P., Rout, A. K., & Sahoo, D. (2022). A state-of-the-art review on potential applications of natural fiber-reinforced polymer composite filled with inorganic nanoparticle. Composites Part C: Open Access. https://doi.org/10.1016/j.jcomc.2022.100298

Jamshidian, M., Tehrany, E. A., Imran, M., Jacquot, M., & Desobry, S. (2010). Poly-Lactic Acid: Production, applications, nanocomposites, and release studies. Comprehensive Reviews in Food Science and Food Safety, 9(5), 552–571. https://doi.org/10.1111/j.1541-4337.2010.00126.x

Farah, S., Anderson, D. G., & Langer, R. (2016). Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Advanced Drug Delivery Reviews. https://doi.org/10.1016/j.addr.2016.06.012

Kim, K., & Baek, S. Y. (2023). Influence of counterpart material on fretting wear of FDM printed polylactic acid plates. International Journal of Precision Engineering and Manufacturing, 24(10), 1855–1863. https://doi.org/10.1007/s12541-023-00806-7

Nirmal Kumar, K., Dinesh Babu, P., Surakasi, R., Kumar, P. M., Ashokkumar, P., Khan, R., Alfozan, A., & Gebreyohannes, D. T. (2022). Mechanical and thermal properties of bamboo fiber-reinforced PLA polymer composites: A critical study. International Journal of Polymer Science, 2022, 1–15. https://doi.org/10.1155/2022/1332157

Roslan, S. A. H., Rasid, Z. A., & Hassan, M. Z. (2018). Bamboo reinforced polymer composite - A comprehensive review. In IOP Conference Series: Materials Science and Engineering (Vol. 344). Institute of Physics Publishing. https://doi.org/10.1088/1757-899X/344/1/012008

Abdul Khalil, H. P. S., Bhat, I. U. H., Jawaid, M., Zaidon, A., Hermawan, D., & Hadi, Y. S. (2012). Bamboo fibre reinforced biocomposites: A review. Materials and Design. https://doi.org/10.1016/j.matdes.2012.06.015

Najjar, I. M. R., Sadoun, A. M., Abd Elaziz, M., Abdallah, A. W., Fathy, A., & Elsheikh, A. H. (2022). Predicting kerf quality characteristics in laser cutting of basalt fibers reinforced polymer composites using neural network and chimp optimization. Alexandria Engineering Journal, 61(12), 11005–11018. https://doi.org/10.1016/j.aej.2022.04.032

Archibong, F. N., Orakwe, L. C., Ogah, O. A., Mbam, S. O., Ajah, S. A., Okechukwu, M. E., Igberi, C. O., Okafor, K. J., Chima, M. O., & Ikelle, I. I. (2023). Emerging progress in montmorillonite rubber/polymer nanocomposites: A review. Journal of Materials Science., 58(6), 2396–2429. https://doi.org/10.1007/s10853-023-08173-4

Moyo, M., Kanny, K., & Mohan, T. P. (2021). Thermo-mechanical response of kenaf/PLA biocomposites to clay nanoparticles infusion. In Materials Today: Proceedings (Vol. 38, pp. 609–613). Elsevier Ltd. https://doi.org/10.1016/j.matpr.2020.03.471

Lotfi, A., Li, H., Dao, D. V., & Prusty, G. (2021). Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. Journal of Thermoplastic Composite Materials. https://doi.org/10.1177/0892705719844546

Moustafa, E. B., & Elsheikh, A. (2023). Predicting characteristics of dissimilar laser welded polymeric joints using a multi-layer perceptrons model coupled with archimedes optimizer. Polymers. https://doi.org/10.3390/polym15010233

Elsheikh, A. H., Shehabeldeen, T. A., Zhou, J., Showaib, E., & Abd Elaziz, M. (2021). Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. Journal of Intelligent Manufacturing, 32(5), 1377–1388. https://doi.org/10.1007/s10845-020-01617-7

Zhou, H., Wu, C., Tang, D., Shi, X., Xue, Y., Huang, Q., Zhang, J., Elsheikh, A. H., & Ibrahim, A. M. M. (2021). Tribological performance of gradient Ag-multilayer graphene/TC4 alloy self-lubricating composites prepared by laser additive manufacturing. Tribology Transactions, 64(5), 819–829. https://doi.org/10.1080/10402004.2021.1922789

Rawal, S., Sidpara, A. M., & Paul, J. (2022). A review on micro machining of polymer composites. Journal of Manufacturing Processes. https://doi.org/10.1016/j.jmapro.2022.03.014

Alsoruji, G., Muthuramalingam, T., Moustafa, E. B., & Elsheikh, A. (2022). Investigation and TGRA based optimization of laser beam drilling process during machining of Nickel Inconel 718 alloy. Journal of Materials Research and Technology, 18, 720–730. https://doi.org/10.1016/j.jmrt.2022.02.112

Kechagias, J. D., Ninikas, K., Petousis, M., & Vidakis, N. (2022). Laser cutting of 3D printed acrylonitrile butadiene styrene plates for dimensional and surface roughness optimization. International Journal of Advanced Manufacturing Technology, 119(3–4), 2301–2315. https://doi.org/10.1007/s00170-021-08350-2

Fountas, N. A., Ninikas, K., Chaidas, D., Kechagias, J., & Vaxevanidis, N. M. (2022). Neural networks for predicting kerf characteristics of CO2 laser-machined FFF PLA/WF plates. MATEC Web of Conferences, 368, 01010. https://doi.org/10.1051/matecconf/202236801010

Petousis, M., Ninikas, K., Vidakis, N., Mountakis, N., & Kechagias, J. D. (2023). Multifunctional PLA/CNTs nanocomposites hybrid 3D printing integrating material extrusion and CO2 laser cutting. Journal of Manufacturing Processes, 86, 237–252. https://doi.org/10.1016/j.jmapro.2022.12.060

Liu, Y., Zhang, S., Zhao, Y., & Ren, Z. (2022). Experiments on the kerf quality characteristic of mild steel while cutting with a high-power fiber laser. Optics and Laser Technology. https://doi.org/10.1016/j.optlastec.2022.108332

Alhawsawi, A. M., Moustafa, E. B., Fujii, M., Banoqitah, E. M., & Elsheikh, A. (2023). Kerf characteristics during CO2 laser cutting of polymeric materials: Experimental investigation and machine learning-based prediction. Engineering Science and Technology, an International Journal, 46, 101519. https://doi.org/10.1016/j.jestch.2023.101519

Mishra, D. R., Bajaj, A., & Bisht, R. (2020). Optimization of multiple kerf quality characteristics for cutting operation on carbon–basalt–Kevlar29 hybrid composite material using pulsed Nd:YAG laser using GRA. CIRP Journal of Manufacturing Science and Technology, 30, 174–183. https://doi.org/10.1016/j.cirpj.2020.05.005

Zeilmann, R. P., & Conrado, R. D. (2022). Effects of cutting power, speed and assist gas pressure parameters on the surface integrity cut by laser. In Procedia CIRP (Vol. 108, pp. 367–371). Elsevier B.V. https://doi.org/10.1016/j.procir.2022.03.060

Kurt, M., Kaynak, Y., Bagci, E., Demirer, H., & Kurt, M. (2009). Dimensional analyses and surface quality of the laser cutting process for engineering plastics. International Journal of Advanced Manufacturing Technology, 41(3–4), 259–267. https://doi.org/10.1007/s00170-008-1468-7

Moradi, M., Moghadam, M. K., Shamsborhan, M., Bodaghi, M., & Falavandi, H. (2020). Post-processing of FDM 3d-printed polylactic acid parts by laser beam cutting. Polymers, 12(3), 550. https://doi.org/10.3390/polym12030550

Muthuramalingam, T., Akash, R., Krishnan, S., Phan, N. H., Pi, V. N., & Elsheikh, A. H. (2021). Surface quality measures analysis and optimization on machining titanium alloy using CO2 based laser beam drilling process. Journal of Manufacturing Processes, 62, 1–6. https://doi.org/10.1016/j.jmapro.2020.12.008

Tahir, A. F. M., & Aqida, S. N. (2017). An investigation of laser cutting quality of 22MnB5 ultra high strength steel using response surface methodology. Optics and Laser Technology, 92, 142–149. https://doi.org/10.1016/j.optlastec.2017.01.005

Pandey, A. K., & Dubey, A. K. (2012). Taguchi based fuzzy logic optimization of multiple quality characteristics in laser cutting of Duralumin sheet. Optics and Lasers in Engineering, 50(3), 328–335. https://doi.org/10.1016/j.optlaseng.2011.11.005

Dubey, A. K., & Yadava, V. (2008). Multi-objective optimization of Nd:YAG laser cutting of nickel-based superalloy sheet using orthogonal array with principal component analysis. Optics and Lasers in Engineering, 46(2), 124–132. https://doi.org/10.1016/j.optlaseng.2007.08.011

Sharma, A., Yadava, V., & Rao, R. (2010). Optimization of kerf quality characteristics during Nd: YAG laser cutting of nickel based superalloy sheet for straight and curved cut profiles. Optics and Lasers in Engineering, 48(9), 915–925. https://doi.org/10.1016/j.optlaseng.2010.03.005

Seo, J., Kim, D. Y., Kim, D. C., & Park, H. W. (2021). Recent developments and challenges on machining of carbon fiber reinforced polymer composite laminates. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-021-00596-w

Xie, Y., Li, W., Liu, C., Du, M., & Feng, K. (2023). Optimization of stamping process parameters based on improved GA-BP neural network model. International Journal of Precision Engineering and Manufacturing, 24(7), 1129–1145. https://doi.org/10.1007/s12541-023-00811-w

Tamrin, K. F., Nukman, Y., Choudhury, I. A., & Shirley, S. (2015). Multiple-objective optimization in precision laser cutting of different thermoplastics. Optics and Lasers in Engineering, 67, 57–65. https://doi.org/10.1016/j.optlaseng.2014.11.001

Venkatesan, K., & Ramanujam, R. (2016). Statistical approach for optimization of influencing parameters in laser assisted machining (LAM) of Inconel alloy. Measurement: Journal of the International Measurement Confederation, 89, 97–108. https://doi.org/10.1016/j.measurement.2016.04.021

Kumar Pandey, A., & Kumar Dubey, A. (2012). Simultaneous optimization of multiple quality characteristics in laser cutting of titanium alloy sheet. Optics and Laser Technology, 44(6), 1858–1865. https://doi.org/10.1016/j.optlastec.2012.01.019

He, G., Du, Y., Liang, Q., Zhou, Z., & Shu, L. (2023). Modeling and optimization method of laser cladding based on GA-ACO-RFR and GNSGA-II. International Journal of Precision Engineering and Manufacturing-Green Technology, 10(5), 1207–1222. https://doi.org/10.1007/s40684-022-00492-2

Elsheikh, A. H., Muthuramalingam, T., Abd Elaziz, M., Ibrahim, A. M. M., & Showaib, E. A. (2022). Minimization of fume emissions in laser cutting of polyvinyl chloride sheets using genetic algorithm. International Journal of Environmental Science and Technology, 19(7), 6331–6344. https://doi.org/10.1007/s13762-021-03566-x

Sibalija, T., Petronic, S., & Milovanovic, D. (2019). Experimental optimization of nimonic 263 laser cutting using a particle swarm approach. Metals, 9(11), 1147. https://doi.org/10.3390/met9111147

Ramesh, M., Sundararaman, K. A., Sabareeswaran, M., & Srinivasan, R. (2022). Development of hybrid artificial neural network-particle swarm optimization model and comparison of genetic and particle swarm algorithms for optimization of machining fixture layout. International Journal of Precision Engineering and Manufacturing, 23(12), 1411–1430. https://doi.org/10.1007/s12541-022-00698-z

Coello Coello, C. A., Pulido, G. T., & Lechuga, M. S. (2004). Handling multiple objectives with particle swarm optimization. IEEE Transactions on Evolutionary Computation, 8(3), 256–279. https://doi.org/10.1109/TEVC.2004.826067

Kennedy, J., & Eberhart, R. (n.d.). Particle swarm optimization. In Proceedings of ICNN’95 - International Conference on Neural Networks (Vol. 4, pp. 1942–1948). IEEE. https://doi.org/10.1109/ICNN.1995.488968

Sibalija, T. V. (2019). Particle swarm optimisation in designing parameters of manufacturing processes: A review (2008–2018). Applied Soft Computing Journal, 84, 105743. https://doi.org/10.1016/j.asoc.2019.105743

Mohanty, C. P., Mahapatra, S. S., & Singh, M. R. (2016). A particle swarm approach for multi-objective optimization of electrical discharge machining process. Journal of Intelligent Manufacturing, 27(6), 1171–1190. https://doi.org/10.1007/s10845-014-0942-3

Sharma, A., & Yadava, V. (2013). Modelling and optimization of cut quality during pulsed Nd:YAG laser cutting of thin Al-alloy sheet for curved profile. Optics and Lasers in Engineering, 51(1), 77–88. https://doi.org/10.1016/j.optlaseng.2012.07.012

Chen, C., Zhang, G., Huang, Y., Rong, Y., Wu, C., Chen, L., & Yang, Z. (2023). Study on the CFRP nanosecond laser cutting damage and efficiency by aspiration system assisted method. Journal of Manufacturing Processes, 102, 95–105. https://doi.org/10.1016/j.jmapro.2023.07.031

Yang, R., Huang, Y., Rong, Y., Wu, C., Liu, W., & Chen, L. (2022). Evaluation and classification of CFRP kerf width by acoustic emission in nanosecond laser cutting. Optics and Laser Technology, 152, 108165. https://doi.org/10.1016/j.optlastec.2022.108165

Elsheikh, A. H., Deng, W., & Showaib, E. A. (2020). Improving laser cutting quality of polymethylmethacrylate sheet: Experimental investigation and optimization. Journal of Materials Research and Technology, 9(2), 1325–1339. https://doi.org/10.1016/j.jmrt.2019.11.059

Khoshaim, A. B., Elsheikh, A. H., Moustafa, E. B., Basha, M., & Showaib, E. A. (2021). Experimental investigation on laser cutting of PMMA sheets: Effects of process factors on kerf characteristics. Journal of Materials Research and Technology, 11, 235–246. https://doi.org/10.1016/j.jmrt.2021.01.012

Ismail, S. O., Dhakal, H. N., Popov, I., & Beaugrand, J. (2016). Comprehensive study on machinability of sustainable and conventional fibre reinforced polymer composites. Engineering Science and Technology, an International Journal, 19(4), 2043–2052. https://doi.org/10.1016/j.jestch.2016.07.010

Pradhan, S., Tripathy, S. S., & Dhupal, D. (2022). Machining of aluminium nitride ceramic using developed hot abrasive jet machining: An experimental and simulation approach. Advances in Materials and Processing Technologies, 8(sup2), 596–610. https://doi.org/10.1080/2374068X.2021.1945275

Wang, D., Tan, D., & Liu, L. (2018). Particle swarm optimization algorithm: An overview. Soft Computing, 22(2), 387–408. https://doi.org/10.1007/s00500-016-2474-6

Escamilla-Salazar, I. G., Torres-Treviño, L. M., González-Ortíz, B., & Zambrano, P. C. (2013). Machining optimization using swarm intelligence in titanium (6Al 4V) alloy. International Journal of Advanced Manufacturing Technology, 67(1–4), 535–544. https://doi.org/10.1007/s00170-012-4503-7

Tripathi, P. K., Bandyopadhyay, S., & Pal, S. K. (2007). Multi-Objective Particle Swarm Optimization with time variant inertia and acceleration coefficients. Information Sciences, 177(22), 5033–5049. https://doi.org/10.1016/j.ins.2007.06.018

Piotrowski, A. P., Napiorkowski, J. J., & Piotrowska, A. E. (2023). particle swarm optimization or differential evolution—A comparison. Engineering Applications of Artificial Intelligence, 121, 106008. https://doi.org/10.1016/j.engappai.2023.106008

Li, C., Xiao, Q., Tang, Y., & Li, L. (2016). A method integrating Taguchi, RSM and MOPSO to CNC machining parameters optimization for energy saving. Journal of Cleaner Production, 135, 263–275. https://doi.org/10.1016/j.jclepro.2016.06.097

Sierra, M. R., & Coello Coello, C. A. (2005). Improving PSO-based multi-objective optimization using crowding, mutation and ∈-dominance (pp. 505–519). https://doi.org/10.1007/978-3-540-31880-4_35

Tamrin, K. F., Moghadasi, K., & Sheikh, N. A. (2020). Experimental and numerical investigation on multi-pass laser cutting of natural fibre composite. International Journal of Advanced Manufacturing Technology, 107(3–4), 1483–1504. https://doi.org/10.1007/s00170-020-05121-3

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, K.N., Babu, P.D. Investigation on Polymer Hybrid Composite Through CO2 Laser Machining for Precise Machining Conditions. Int. J. Precis. Eng. Manuf. 25, 1043–1061 (2024). https://doi.org/10.1007/s12541-023-00942-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00942-0