Abstract

Reasonable process parameters are the key measures to ensure the quality of stamping products. In order to reduce the risk of cracking and wrinkling of stamping products, an improved genetic algorithm is proposed and used to optimize the weights and thresholds of the BP neural network(BPNN). A surrogate model combining an improved genetic algorithm and BPNN(IGA-BPNN)is developed. Taking double C as the research object, the training samples and test samples are extracted through Latin hypercube. The training output of IGA-BPNN model is obtained by AutoForm simulation, and the mapping relationship between process parameters and forming quality is established. Then the mapping relationship is optimized by IGA to obtain the optimal process parameters. The results show that this method reduces the wrinkling of the flange edge of double C and obviously improves the forming quality.

Similar content being viewed by others

Code Availability

The sample data in this article is generated by AutoForm software, and the original program code is written by the author himself. The improvement and operation of the program are realized in MATLAB. The full datasets, as well as the source codes, can be available from the corresponding author with reasonable request.

References

Yan, G., Zheng, Y. P., Wang, L. L., & Huang, Z. M. (2020). Optimization of stamping process parameters based on orthogonal test and intelligent algorithm. 2020 3rd World conference on mechanical engineering and intelligent manufacturing (WCMEIM2020) (pp. 393–397).

Badgujar, T. Y., & Wani, V. P. (2018). Stamping process parameter optimization with multiple regression analysis approach. Materials Today-Proceedings, 5(2), 4498–4507.

Wang, N., Chen, G. L., & Chen, M. H. (2014). Constitutive relationship and parameters optimization of 6181 H18 aluminum alloy hot forming process with synchronous cooling. Advances in Materials Manufacturing Science and Technology XV, 770, 324–328.

Sherbiny, M. E., Zein, H., Abd-Rabou, M., et al. (2014). Thinning and residual stresses of sheet metal in the deep drawing process. Materials & Design, 55, 869–879.

Kim, H., Ji, H. S., Sivakumar, R., et al. (2007). Evaluation of stamping lubricants using the deep drawing test. International Journal of Machine Tools Manufacture, 47(14), 2120–2132.

Xie, H., & Ling, H. W. (2016). Analysis and optimization of hot stamping die wear based on archard theory. Hot Working Technology, 45(1), 100–104.

Han, Z. (2016). Kriging surrogate model and its application to design optimization: A review of recent progress. Acta Aeronautica Et Astronautica Sinica, 37, 3197–3225.

Ramesh, M., Sundararaman, K. A., Sabareeswaran, M., & Srinivasan, R. (2022). Development of hybrid artificial neural network-particle swarm optimization model and comparison of genetic and particle swarm algorithms for optimization of machining fixture layout. International Journal of Precision Engineering and Manufacturing, 23(12), 1411–1430.

Long, L., Yin, G. F., Zou, Y., & Xiao, B. (2012). Optimization of stamping process based on stochastic focusing search algorithm. Jisuanji Jicheng Zhizao Xitong/Computer Integrated Manufacturing Systems, 18(2), 314–320.

Yu, S. H., Zhao, R. M., Li, J. Q., He, X. M., & Jiang, X. (2014). Optimization of sheet metal stamping process based on multi-objective particle swarm algorithm. Hot Working Technology, 43(1), 144–147.

Sun, G., Li, G., Gong, Z., Cui, X., Yang, X., & Li, Q. (2010). Multiobjective robust optimization method for drawbead design in sheet metal forming. Materials & Design, 31(4), 1917–1929.

Khawaja, A. H., Jahanzaib, M., & Munawar, M. (2021). Optimizing the performance of high-speed machining on 15CDV6 HSLA steel in terms of green manufacturing using response surface methodology and artificial neural network. International Journal of Precision Engineering and Manufacturing., 22(6), 1125–1145.

Xiao, W., Wang, B., Zhou, J., Ma, W. Y., & Yang, L. (2016). Optimization of aluminium sheet hot stamping process using a multi-objective stochastic approach. Engineering Optimization, 48(12), 2173–2189.

Yang, X. J., Feng, X. L., Zheng, J., & Guo, S. J. (2015). Application of SVM and improved particle swarm optimization in stamping forming optimization. Automotive Engineering, 37(04), 485–489.

Dang, V. T., Lafon, P., & Labergere, C. (2017). Surrogate models for sheet metal stamping problem based on the combination of proper orthogonal decomposition and radial basis function. In International conference of global network for innovative technology & awam international conference in civil engineering.

Jinda, Hu. (2020). Gaussian disturbance particle swarm optimization for stamping process of automobile rear panel inner panel. Forging Technology, 45(12), 46–52.

Wang, M. B. (2021). Genetic algorithm multi-objective optimization of hot stamping process for automotive B-pillar reinforcement plate. Forging Technology, 46(05), 46–52.

Yu, S., Zhu, K., & Gao, S. (2009). A hybrid MPSO-BP structure adaptive algorithm for RBFNs. Neural Computing and Applications, 18(7), 769–779.

Hu, K., Zhang, G. L., & Xiong, B. (2018). An improved particle swarm algorithm for constrained optimization problem. In International conference on machine learning and cybernetics.

Chen, X. Z., & Zhan, Q. (2021). The kinematic calibration of a drilling robot with optimal measurement configurations based on an improved multi-objective PSO algorithm. International Journal of Precision Engineering and Manufacturing., 22(9), 1537–1549.

Li, X., Li, C., Li, P., Hu, H., & Sui, X. (2021). Structural design and optimization of the crossbeam of a computer numerical controlled milling-machine tool using sensitivity theory and NSGA-II algorithm. International Journal of Precision Engineering and Manufacturing., 22(2), 287–300.

Sun, M., Ji, C. Y., Luan, T. T., & Wang, N. (2023). LQR pendulation reduction control of ship-mounted crane based on improved grey wolf optimization algorithm. International Journal of Precision Engineering and Manufacturing., 24, 395–407.

Wang, X. Y., Liu, Y. M., Zhang, G. W., & Lin, J. Q. (2018). Prediction of aircraft cabin energy consumption based on improved cooperative PSO neural network. Journal of System Simulation, 30(04), 1535–1541.

Lu, K. Z., Wang, R. Z., & Shuai, X. Y. (2007). Improving particle swarm optimization by keeping particles active. Computer Engineering & Applications, 43(11), 35–38.

Zhu, Y., Zhou, L., & Xu, H. (2020). Application of improved genetic algorithm in ultrasonic location of transformer partial discharge. Neural Computing and Applications, 32(6), 1755–1764.

Chen, L., Zhang, F., & Sun, L. (2020). Research on the calibration of binocular camera based on BP neural network optimized by improved genetic simulated annealing algorithm. IEEE Access, 8, 103815–103832.

Xie, Y. M., Du, L. F., Zhao, J., Liu, C., & Li, W. (2021). Multi-objective optimization of process parameters in stamping based on an improved RBM–BPNN network and MOPSO algorithm. Structural and Multidisciplinary Optimization, 64(6), 4209–4235.

Tian, Y. B., Chen, F., & Zhang, Z. K. (2015). Hybrid neural network technology. Beijing: Science Press.

Yang, H., Li, X., Qiang, W., et al. (2021). A network traffic forecasting method based on SA optimized ARIMA-BP neural network. Computer Networks, 193(3), 108102.

Ren, Z. W., & San, Y. (2007). Improvement and performance research of real number genetic algorithm. Journal of Electronics, 02, 269–274.

Srinivas, M., & Patnaik, L. M. (2002). Adaptive probabilities of crossover and mutation in genetic algorithms. IEEE Transactions on Systems Man & Cybernetics, 24(4), 656–667.

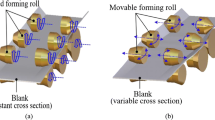

Huang, R. Y., Xie, Y. M., Tang, W., et al. (2017). Simulation and experiment of torsional springback of TRIP780 high-strength steel double C beam based on hybrid hardening model. Journal of Engineering Design, 24(6), 7.

Djouabi, M., Ati, A., & Manach, P. Y. (2018). Identification strategy influence of elastoplastic behavior law parameters on Gurson–Tvergaard–Needleman damage parameters: Application to DP980 steel. International Journal of Damage Mechanics, 28(3), 105678951877213.

Fang, K. T., Li, R., & Sudjianto, A. (2006). Design and modeling for computer experiments. Chapman & Hall/CRC.

Acknowledgements

This work is supported by the Key Laboratory of Mechanical Structure Optimization & Material Application Technology of Luzhou in China (Optimization design of blank holders in in nonisothermal stamping based on CAE, SCHYZSA-2022-04).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xie, Y., Li, W., Liu, C. et al. Optimization of Stamping Process Parameters Based on Improved GA-BP Neural Network Model. Int. J. Precis. Eng. Manuf. 24, 1129–1145 (2023). https://doi.org/10.1007/s12541-023-00811-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00811-w