Abstract

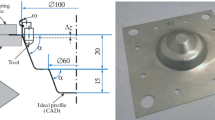

Stamping is the main manufacturing process for sheet metal parts. However, during the stamping process, based on excessive blank holder force, unreasonable mold design, and other factors, it is easy to generate defects such as cracks in the drawing area and flange wrinkles. In this paper, a novel hybrid model based on a restricted Boltzmann machine and back-propagation neural network is proposed and its validity is verified through different testing functions. Additionally, an improved multi-objective particle swarm optimization (MOPSO) method based on a crowding operator is proposed and compared to several powerful existing algorithms. The proposed method was applied to the process optimization of a double-C part. The sensitivity of the forming quality to different process parameters was analyzed and a novel index was used to describe quality changes. A mapping relationship between the process parameters and forming quality was established based on the proposed hybrid model. Furthermore, optimal process parameters were obtained using MOPSO. The results demonstrated that the proposed method significantly reduces flange wrinkles without excessive thinning and improves the uniformity of formed parts.

Similar content being viewed by others

References

Adorio EP, Diliman UP (2005) MVF-Multivariate test functions library in C for unconstrained global optimization. http://www.geocities.ws/eadorio/mvf.pdf

Bici M, Campana F, Cimolin F, Rizzo L (2019) Robust die compensation in sheet metal design through the integration of dual response surface and shape function optimization. Math Probl Eng 2019:1–12. https://doi.org/10.1155/2019/7357135

Chokshi P, Dashwood R, Hughes DJ (2017) Artificial Neural Network (ANN) based microstructural prediction model for 22MnB5 boron steel during tailored hot stamping. Comput Struct 190:162–172. https://doi.org/10.1016/j.compstruc.2017.05.015

Coello CAC, Pulido GT, Lechuga MS (2004) Handling multiple objectives with particle swarm optimization. IEEE Trans Evol Comput 8(3):256–279. https://doi.org/10.1109/TEVC.2004.826067

Dang VT, Labergere C, Lafon P (2017) POD surrogate models using adaptive sampling space parameters for springback optimization in sheet metal forming. Procedia Eng 207:1588–1593. https://doi.org/10.1016/j.proeng.2017.10.1053

Dhiman G, Kaur A (2019) HKn-RVEA: a novel many-objective evolutionary algorithm for car side impact bar crashworthiness problem. Int J Veh Des 80(2–4):257–284. https://doi.org/10.1504/IJVD.2019.109869

Fang KT, Li R, Sudjianto A (2006) Design and modeling for computer experiments. Chapman & Hall/CRC, Boca Raton

Gao MD, Wang QY, Li L, Ma ZL (2020) Energy-economizing optimization of magnesium alloy hot stamping process. Processes 8(2):186. https://doi.org/10.3390/pr8020186

Han ZH (2016) Kriging surrogate model and its application to design optimization: a review of recent progress. Acta Aeronaut ET Astronaut Sinica 37(11):3197–3225

He F, Shen K, Guan L, Jiang MM (2017) Research on energy-saving scheduling of a forging stock charging furnace based on an improved SPEA2 algorithm. Sustainability 9(12):2154. https://doi.org/10.3390/su9112154

Huang CY, Dzulfikri Z (2021) Stamping monitoring by using an adaptive 1D convolutional neural network. Sensors 21(1):262. https://doi.org/10.3390/s21010262

Khalkhali A, Noraie H, Sarmadi M (2017) Sensitivity analysis and optimization of hot-stamping process of automotive components using analysis of variance and Taguchi technique. J Process Mech Eng 231(4):732–746. https://doi.org/10.1177/0954408916633491

Kim H, Sung JH, Sivakumar R, Altan T (2007) Evaluation of stamping lubricants using the deep drawing test. Int J Mach Tools Manuf 47(14):2120–2132. https://doi.org/10.1016/j.ijmachtools.2007.04.014

Li F, Liu JC, Tan SB, Yu X (2015) R2-MOPSO: A multi-objective particle swarm optimizer based on R2-indicator and decomposition. IEEE Congress Evol Comput. https://doi.org/10.1109/CEC.2015.7257282

Li HH, Hu ZL, Hua L, Chen YZ (2019) Optimization of hot forming-quenching integrated process parameters for complex aluminum alloy automotive components. Rare Metal Mater Eng 48(4):1029–1035

Mahmud MSA, Abidin MSZ, Buyamin S, Emmanuel AA, Hasan HS (2021) Multi-objective route planning for underwater cleaning robot in water reservoir tank. J Intell Robot Syst 101(1):9. https://doi.org/10.1007/s10846-020-01291-0

Panagant N, Pholdee N, Bureerat S, Yildiz AR, Mirjalili S (2021) A comparative study of recent multi-objective metaheuristics for solving constrained truss optimization problems. Arch Computat Methods Eng. https://doi.org/10.1007/s11831-021-09531-8

Picheny V, Wagner T, Ginsbourger D (2013) A benchmark of kriging-based infill criteria for noisy optimization. Struct Multidisc Optim 48(3):607–626. https://doi.org/10.1007/s00158-013-0919-4

Sherbiny MEI, Zein H, Abd-Rabou M, Shazly MEI (2014) Thinning and residual stresses of sheet metal in the deep drawing process. Mater Des 55:869–879. https://doi.org/10.1016/j.matdes.2013.10.055

Spathopoulos SC, Stavroulakis GE (2020) Springback prediction in sheet metal forming, based on finite element analysis and artificial neural network approach. Appl Mech 1(2):97–110. https://doi.org/10.3390/applmech1020007

Tan YY, Jiao YC, Li H, Wang XK (2012) MOEA/D-SQA: a multi-objective memetic algorithm based on decomposition. Eng Optim 44(9):1095–1115. https://doi.org/10.1080/0305215X.2011.632008

Tang W, Xie YM, Huang RY, Zhang F, Pan BB (2017) Constitutive parameter inverse for nonisothermal stamping of magnesium alloy based on adaptive SVR-ELM mixture surrogate model. Chin J Eng Des 24(5):536–544

Tawhid MA, Savsani V (2019) Multi-objective sine-cosine algorithm (MO-SCA) for multi-objective engineering design problems. Neural Comput Appl 31:915–929. https://doi.org/10.1007/s00521-017-3049-x

Trivedi M, Shrivastava R (2020) Derivation and performance evaluation of optimal operating policies for a reservoir using a novel PSO with elitism and variational parameters. Urban Water J 17(9):774–784. https://doi.org/10.1080/1573062X.2020.1823431

Wang H, Li EY, Li GY (2010) Parallel boundary and best neighbor searching sampling algorithm for drawbead design optimization in sheet metal forming. Struct Multidisc Optim 41:309–324. https://doi.org/10.1007/s00158-009-0411-3

Wang HY, Xie H, Cheng W, Liu QM, Shen YF (2018) Multi-objective optimisation on crashworthiness of front longitudinal beam (FLB) coupled with sheet metal stamping process. Thin-Walled Struct 132:36–47. https://doi.org/10.1016/j.tws.2018.07.050

Xie YM, Xiong WC, Zhuo DZ, Wang XB (2016) Drawbead geometric parameters using an improved equivalent model and PSO-BP neural network. Proc Inst Mech Eng Part l J Mater Des Appl 230(4):899–910. https://doi.org/10.1177/1464420715587024

Xie YM, Zhang F, Pan BB, Feng MQ, Yue YP (2019) Optimization of drawbeads based on parallel infilling strategy and kriging models. J Mech Eng 55(8):73–79

Xu M, Li B (2017) Optimization of forming process parameters for transmission belt based on response surface method. Int Conf Robots Intell Syst. https://doi.org/10.1109/ICRIS.2017.65

Yi JH, Deb S, Dong JY, Alavi AH, Wang GG (2018) An improved NSGA-III algorithm with adaptive mutation operator for Big Data optimization problems. Futur Gener Comput Syst 88:571–585. https://doi.org/10.1016/j.future.2018.06.008

Ying L, D MH, Zhang SZ, Ma HL, Hu P, (2017) Multiobjective crashworthiness optimization of thin-walled structures with functionally graded strength under oblique impact loading. Thin-Walled Struct 117:165–177. https://doi.org/10.1016/j.tws.2017.04.007

Zhang QF, Li H (2007) MOEA/D: A multiobjective evolutionary algorithm based on decomposition. IEEE Trans Evol Comput 11(6):712–731. https://doi.org/10.1109/TEVC.2007.892759

Zhang HW, Zheng XT (2020) Blank holder force prediction of tailor welded blank based on neural network optimized by genetic algorithm. J Northeastern Univ (Nat Sci) 41(2):241–245

Zhang XY, Zheng XT, Cheng R, Qiu JF, Jin YC (2018) A competitive mechanism based multi-objective particle swarm optimizer with fast convergence. Inf Sci 427:63–76. https://doi.org/10.1016/j.ins.2017.10.037

Funding

This work was supported by the Sichuan Science and Technology Program (2020YFH0078; 2019YFG0313).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Replication of results

The sample data used in this study were generated by the AutoForm software and the original program code was taken from https://emoo.cs.cinvestav.mx/software.php. The program was optimized and executed in MATLAB. The full datasets, as well as the source code, can be obtained from the corresponding author upon reasonable request.

Additional information

Responsible Editor: Christian Gogu

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, Y., Du, L., Zhao, J. et al. Multi-objective optimization of process parameters in stamping based on an improved RBM–BPNN network and MOPSO algorithm. Struct Multidisc Optim 64, 4209–4235 (2021). https://doi.org/10.1007/s00158-021-03056-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-021-03056-1