Abstract

When the welded part of a vehicle body is considered in an analysis model, the accuracy of the analysis varies depending on whether the welded part is assumed to be a simple rigid body or if its characteristics are included. Particularly, when assuming a simple rigid body, the accuracy of the stress result may be insufficient, resulting in a large error. In this study, titled “part 2-development of finite element method (FEM) analysis model for predicting fracture strength”, a commercial welding simulation program, MSC Simufact welding software, was used to create a finite element method analysis model that includes the material characteristics of the welded part, and the analysis accuracy was determined in comparison with the experimental results presented in part 1. The analysis results showed satisfactory results with an error rate of 0.03%. Thus, the fracture strength and fracture position of the welding specimen could be confirmed using the FEM analysis model. Additionally, assuming that the welded part in spot welding has a simple geometric-shaped structure, a simplification spot welding model was created to determine whether it can replace the plasma arc spot welding experiment and pass the tensile shear test.

Similar content being viewed by others

References

Zaman, I., & Rahman, R. A. (2006). Application of dynamic correlation technique and model updating on truck chassis. In Proceeding of 1st regional conference on vehicle engineering and technology.

Chcc, N. C. (2007). Finite element modeling of arc welded joints. Jurnal Mekanikal, 23.

Vakili-Tahami, F., & Ziaei-Asl, A. (2013). Numerical and experimental investigation of T-shape fillet welding of AISI 304 stainless steel plates. Materials & Design, 47, 615–623.

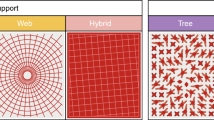

Xu, S., & Deng, X. (2004). An evaluation of simplified finite element models for spot-welded joints. Finite Elements in Analysis and Design, 40(9–10), 1175–1194.

Song, S., et al. (2015). Development of simplified finite element models for welded joints. Transactions of the Korean Society of Mechanical Engineers A, 39(11), 1191–1198.

Goo, B. C., Choi, B., & Kim, J. H. (2004). Finite element analysis of the stress concentrations for butt welded joints. Journal of Welding and Joining, 22(4), 59–64.

Mirzaei, F., Ghorbani, H., & Kolahan, F. (2017). Numerical modeling and optimization of joint strength in resistance spot welding of galvanized steel sheets. The International Journal of Advanced Manufacturing Technology, 92(9), 3489–3501.

Jun, H. U., et al. (2020). The effect of pre-welding on nugget growth behavior and weldability for the resistance spot welding of A6014–T4 alloy. Journal of Welding and Joining, 38(2), 203–210.

Cho, H., et al. (2020). Predicting failure modes of resistance spot welds from the chemical composition of materials. Journal of Welding and Joining, 38(5), 450–459.

Lee, T. S., Lee, H. Y., & Shin, S. J. (1998). An estimative model of spot weld failure-1. Failure criteria. Transactions of the Korean Society of Automotive Engineers, 6(6), 40–52.

Askeland, D. R., & Wright, W. J. (2018). Essentials of materials science and engineering. In Cengage learning (pp. 185–205).

Zina, N., et al. (2019). Numerical simulation on the effect of friction stir welding parameters on the peak temperature, von Mises stress, and residual stresses of 6061-T6 aluminum alloy. Journal of Failure Analysis and Prevention, 19(6), 1698–1719.

Park, J. H., & Kim, J. W. (2011). A study on the optimum line heating condition for straightening a thin plate welded structure. Journal of Welding and Joining, 29(2), 40–45.

KS B 0850. Method of inspection for spot weld. Korean Standards Association.

Acknowledgement

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No.2021R1A4A1033141) and (No.2021R1F1A106-4238).

Author information

Authors and Affiliations

Contributions

All authors contributed to this paper. Simulation were performed by Geonho Lee, Hansol Kim, Jongho Jeon, and Sangjun Han. Data analysis and result considerations were performed by Geonho Lee, Sang-Woo Han, and Jungho Cho. The first draft of the manuscript was written by Geonho Lee, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, G., Kim, H., Jeon, J. et al. Development of Plasma Arc Spot Welding Process and Finite Element Method Analysis Model for Predicting Fracture Strength: Part 2—Development of Finite Element Method Analysis Model for Predicting Fracture strength. Int. J. Precis. Eng. Manuf. 24, 13–23 (2023). https://doi.org/10.1007/s12541-022-00706-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-022-00706-2