Abstract

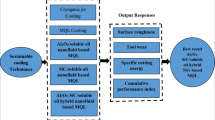

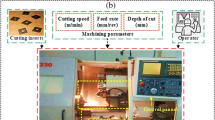

The present study investigated the effect of different machining environments such as dry, wet, cryogenic cooling, minimum quantity lubrication (MQL), Al2O3 nanofluids with MQL, CuO nanofluids with MQL and Al–CuO hybrid nanofluids with MQL on machining performance characteristics during turning of EN-24 steel. The nanofluids and hybrid nanofluids were prepared by adding different weight percentages (0.2 wt%, 0.4 wt%, 0.6 wt%) of Al2O3, CuO and Al–CuO to the soluble oil. The thermal and tribological properties of soluble oil, nanofluids and hybrid nanofluids were analysed. The thermal conductivity of Al–CuO hybrid nanofluids was more compared with Al2O3, CuO nanofluids. The specific heat of Al–CuO hybrid nanofluids was less compared with Al2O3, CuO nanofluids. The comparative analysis of machining performance was done during turning under different environments. Experimental results reveal that the turning performance under Al–CuO hybrid nanofluids with MQL was better as compared to other machining environments.

Similar content being viewed by others

References

Thirumalai, R., Senthilkumaar, J. S., Selvarani, P., & Ramesh, S. (2013). Machining characteristics of Inconel 718 under several cutting conditions based on Taguchi method. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 227(9), 1889–1897.

Astakgov, V. P. (Ed.). (2008). Ecological machining: Near dry machining. In Book machining: Fundamentals and recent advances. London: Springer, pp. 195–223.

Ramesh, S., Palanikumar, K., Elangovan, K., & Karunamoorthy, L. (2008). Machining titanium alloy with pulsed injecting coolant technique to improve a eco-friendly environment in industries. In Proceedings of the 19th AeroMat conference and exposition.

Kline and Company, Inc. (2006). Competitive intelligence for the global lubricants industry (pp. 4–14). Parsippany: Kline and company.

Yildiz, Y., & Nalbant, M. (2008). A review of cryogenic cooling in machining processes. International Journal of Machine Tool and Manufacturing, 48(9), 947–964.

Hong, S. Y. (1999). Milling tool with rotary cryogenic coolant coupling, Patent Cooperation Treaty (PCT), WO 99/60079.

Hong, S. Y. (2001). Economical and ecological cryogenic machining. Journal of Manufacturing Science and Engineering, 123(2), 331–338.

Dhar, N. R., Paul, S., & Chattopadhyay, A. B. (2002). Role of cryogenic cooling on cutting temperature in turning steel. Journal of Manufacturing Science and Engineering, 124(1), 146–154.

Paul, S., Dhar, N. R., & Chattopadhyay, A. B. (2001). Beneficial effects of cryogenic cooling over dry and wet machining on tool wear and surface finish in turning AISI 1060 steel. Journal of Materials Processing and Technology, 116(1), 44–48.

Dhar, N. R., & Kamruzzaman, M. (2007). Cutting temperature, tool wear, surface roughness and dimensional deviation in turning AISI-4037 steel under cryogenic condition. International Journal of Machine Tool and Manufacturing, 47(5), 754–759.

Hong, S. Y., & Zhao, Z. (1999). Thermal aspects, material considerations and cooling strategies in cryogenic machining. Clean Products and Processes, 1, 107–116.

Klocke, F., Lung, D., Arft, M., Priarone, P. C., & Settineri, L. (2013). On high-speed turning of a third-generation gamma titanium aluminide. International Journal of Advanced Manufacturing Technology, 64, 155–163.

Umbrello, D., Micari, F., & Jawahir, I. S. (2012). The effects of cryogenic cooling on surface integrity in hard machining: A comparison with dry machining. CIRP Annals Manufacturing Technology, 61, 103–106.

Leadebal, W. V., Jr., de Melo, A. C. A., de Oliveira, A. J., & Castro, N. A. (2018). Effects of cryogenic cooling on the surface integrity in hard turning of AISI D6 steel. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 40(1), 15.

Khan, M. M. A., & Dhar, N. R. (2006). Performance evaluation of minimum quantity lubrication by vegetable oil in terms of cutting force, cutting zone temperature, tool wear, job dimension and surface finish in turning AISI-1060 steel. Journal of Zhejiang University Science A, 7(11), 1790–1799.

Maruda, R. W., Feldshtein, E., Legutko, S., & Krolczyk, G. M. (2016). Analysis of contact phenomena and heat exchange in the cutting zone under minimum quantity cooling lubrication conditions. Arabian Journal for Science and Engineering, 41(2), 661–668.

Yıldırım, Ç. V., Kıvak, T., Sarıkaya, M., & Erzincanlı, F. (2017). Determination of MQL parameters contributing to sustainable machining in the milling of nickel-base superalloy was paloy. Arabian Journal for Science and Engineering, 42(11), 4667–4681.

Dhar, N. R., Kamruzzaman, M., & Ahmed, M. (2006). Effect of minimum quantity lubrication (MQL) on tool wear and surface roughness in turning AISI-4340 steel. Journal of Materials Processing and Technology, 172(2), 299–304.

Attanasio, A., Gelfi, M., Giardini, C., & Remino, C. (2006). Minimal quantity lubrication in turning: Effect on tool wear. Wear, 260(3), 333–338.

Dhar, N. R., Ahmed, M. T., & Islam, S. (2007). An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. International Journal of Machine Tool and Manufacturing, 47(5), 748–753.

Davim, J. P., Sreejith, P. S., & Silva, J. (2007). Turning of brasses using minimum quantity of lubricant (MQL) and flooded lubricant conditions. Material and Manufacturing Processes, 22(1), 45–50.

Khan, M. M. A., Mithu, M. A. H., & Dhar, N. R. (2009). Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. Journal of Materials Processing and Technology, 209(15–16), 5573–5583.

Ji, X., Li, B., Zhang, X., & Liang, S. Y. (2014). The effects of minimum quantity lubrication (MQL) on machining force, temperature, and residual stress. International Journal of Precision Engineering and Manufacturing, 15(11), 2443–2451.

Liao, Y. S., Liao, C. H., & Lin, H. M. (2017). Study of oil-water ratio and flow rate of MQL fluid in high speed milling of Inconel 718. International Journal of Precision Engineering and Manufacturing, 18(2), 257–262.

Nguyen, T. K., Do, I., & Kwon, P. A. (2012). Tribological study of vegetable oil enhanced by nano-platelets and implication in MQL machining. International Journal of Precision Engineering and Manufacturing, 13(7), 1077–1083.

Viswanathan, R., Ramesh, S., & Subburam, V. (2018). Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Measurement, 120, 107–113.

Hadad, M., & Sadeghi, B. (2013). Minimum quantity lubrication-MQL turning of AISI 4140 steel alloy. Journal of Cleaner Production, 54, 332–343.

Al Kalbani, K. S., & Rahman, M. M. (2018). Investigation of the local thermal non equilibrium conditions for a convective heat transfer flow in an inclined square enclosure filled with Cu–Water Nanofluids. Arabian Journal for Science and Engineering, 1–5.

Kim, H. J., Seo, K. J., Kang, K. H., & Kim, D. E. (2016). Nano-lubrication: A review. International Journal of Precision Engineering and Manufacturing, 17(6), 829–841.

Hamida, M. B., Belghaieb, J., & Hajji, N. (2018). Heat and mass transfer enhancement for falling film absorption process in vertical plate absorber by adding copper nanoparticles. Arabian Journal for Science and Engineering, 43, 4991–5001.

Nam, J. S., Lee, P. H., & Lee, S. W. (2011). Experimental characterization of micro-drilling process using nanofluids minimum quantity lubrication. International Journal of Machine Tool and Manufacturing, 51(7–8), 649–652.

Mia, M., Al Bashir, M., Khan, M. A., & Dhar, N. R. (2017). Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). International Journal Advanced Manufacturing Technology, 89(1–4), 675–690.

Najiha, M. S., Rahman, M. M., & Kadirgama, K. (2016). Performance of water-based TiO2 nanofluids during the minimum quantity lubrication machining of aluminium alloy, AA6061-T. Journal of Cleaner Production, 135, 1623–1636.

Lee, P. H., Nam, J. S., Li, C., & Lee, S. W. (2012). An experimental study on micro-grinding process with nanofluids minimum quantity lubrication (MQL). International Journal of Precision Engineering and Manufacturing, 13(3), 331–338.

Vasu, V., & Pradeep Kumar Reddy, G. (2011). Effect of minimum quantity lubrication with Al2O3 nanoparticles on surface roughness, tool wear and temperature dissipation in machining Inconel 600 alloy. Proceedings of the Institution of Mechanical Engineers, Part N: Journal of Nano engineering and Nanosystems, 225(1), 3–16.

Amrita, M., Srikant, R. R., Sitaramaraju, A. V., Prasad, M. M. S., & Krishna, P. V. (2013). Experimental investigations on influence of mist cooling using nanofluids on machining parameters in turning AISI 1040 steel. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 227(12), 1334–1346.

Sharma, P., Sidhu, B. S., & Sharma, J. (2015). Investigation of effects of nanofluids on turning of AISI D2 steel using minimum quantity lubrication. Journal of Cleaner Production, 108, 72–79.

Khandekar, S., Sankar, M. R., Agnihotri, V., & Ramkumar, J. (2012). Nano-cutting fluid for enhancement of metal cutting performance. Journal of Manufacturing Processes, 27(9), 963–967.

Sharma, A. K., Singh, R. K., Dixit, A. R., & Tiwari, A. K. (2017). Novel uses of alumina-MoS2 hybrid nanoparticle enriched cutting fluid in hard turning of AISI 304 steel. Journal of Manufacturing Processes, 30, 467–482.

Sharma, A. K., Tiwari, A. K., Dixit, A. R., Singh, R. K., & Singh, M. (2018). Novel uses of alumina/graphene hybrid nanoparticle additives for improved tribological properties of lubricant in turning operation. Tribology International, 119, 99–111.

Kanthavel, K., Sumesh, K., & Saravanakumar, P. (2016). Study of tribological properties on Al/Al2O3/MoS2 hybrid composite processed by powder metallurgy. Alexandria Engineering Journal, 55, 13–17.

Singh, R. K., Sharma, A. K., Dixit, A. R., Tiwari, A. K., Pramanik, A., & Mandal, A. (2017). Performance evaluation of alumina-graphene hybrid nano-cuttingfluid in hard turning. Journal of Cleaner Production. https://doi.org/10.1016/j.jclepro.2017.06.104.

Choi, S. U., & Eastman, J. A. (1995). Enhancing thermal conductivity of fluids with nanoparticles (No. ANL/MSD/CP–84938; CONF-951135–29). Lemont, IL: Argonne National Lab.

Kalpakjain, S., Schmid, S. R., & Sekar, K. S. V. (2014). Manufacturing engineering and technology. Agenda 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Thakur, A., Manna, A. & Samir, S. Performance Evaluation of Different Environmental Conditions on Output Characteristics During Turning of EN-24 Steel. Int. J. Precis. Eng. Manuf. 20, 1839–1849 (2019). https://doi.org/10.1007/s12541-019-00179-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00179-w