Abstract

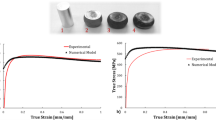

Gamma titanium aluminides are heat-resistant intermetallic alloys predestined to be employed in components suffering from high mechanical stresses and thermal loads. These materials are regarded as difficult to cut, so this makes process adaptation essential in order to obtain high-quality and defect-free surfaces suitable for aerospace and automotive parts. In this paper, an innovative approach for longitudinal external high-speed turning of a third-generation Ti-45Al-8Nb-0.2C-0.2B gamma titanium aluminide is presented. The experimental campaign has been executed with different process parameters, tool geometries and lubrication conditions. The results are discussed in terms of surface roughness/integrity, chip morphology, cutting forces and tool wear. Experimental evidence showed that, due to the high cutting speed, the high temperatures reached in the shear zone improve chip formation, so a crack-free surface can be obtained. Furthermore, the use of a cryogenic lubrication system has been identified in order to reduce the huge tool wear, which represents the main drawback when machining gamma titanium aluminides under the chosen process conditions.

Similar content being viewed by others

References

Aguilar J, Arft M, Grüneberg C, Guntlin R, Kättlitz O, Klocke F, Lung D (2011) Fliegen leicht gemacht. RWTH Themen 1:40–42

Loria EA (2000) Gamma titanium aluminides as a prospective structural materials. Intermetallics 8:1339–1345

Loria EA (2001) Quo vadis gamma titanium aluminide. Intermetallics 9:997–1001

Weinert K, Bergmann S, Kempmann C (2006) Machining sequence to manufacture a γ-TiAl-conrod for application in combustion engines. Adv Eng Mater 8:41–47

Austin CM (1999) Current status of gamma titanium aluminides for aerospace applications. Curr Opin Solid State Mater Sci 4:239–242

Tetsui T (1999) Gamma Ti aluminides for non-aerospace applications. Curr Opin Solid State Mater Sci 4:243–248

Aspinwall DK, Dewes RC, Mantle AR (2005) The machining of γ-TiAl intermetallic alloys. CIRP Ann 54(1):99–104

Sharman ARC, Aspinwall DK, Dewes D, Clifton RC, Bowen P (2001) The effects of machined workpiece surface integrity on the fatigue life of γ-titanium aluminide. Int J Mach Tool Manuf 41:1681–1685

Sharman ARC, Aspinwall DK, Dewes RC, Bowen P (2001) Workpiece surface integrity considerations when finish turning gamma titanium aluminide. Wear 249:473–481

Mantle AL, Aspinwall DK (1997) Surface integrity and fatigue life of turned gamma titanium aluminide. J Mater Process Technol 72:413–420

Bentley SA, Goh NP, Aspinwall DK (2001) Reciprocating surface grinding of a gamma titanium aluminide intermetallic alloy. J Mater Process Technol 118:22–28

Gröning H, Klocke F, Weiß M (2009) Schleifen von gamma-Titanaluminden. wt-Werkstatttechnik online Jahrgang 99

Mantle AL, Aspinwall DK (2001) Surface integrity of a high speed milled gamma titanium aluminide. J Mater Process Technol 118:143–150

Beranoagirre A, Olvera D, López de Lacalle LN (2011) Milling of gamma titanium–aluminum alloys. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3812-6

Priarone PC, Rizzuti S, Rotella G, Settineri L (2011) Tool wear and surface quality in milling of a gamma-TiAl intermetallic. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3691-x

Beranoagirre A, Olvera D, Urbicain G, López de Lacalle LN, Lamikiz A (2010) Hole making in gamma TiAl. DAAAM Int Sci Book 2010:337–346

Beranoagirre A, López de Lacalle LN (2011) Turning of gamma TiAl intermetallic alloys. Proceedings of the 4th Manufacturing Engineering Society International Conference

Uhlmann E, Schauerte O, Brücher M, Herter S (2001) Tool wear during turning of titanium aluminide intermetallics. Prod Eng 8(2):13–16

Bergmann S (2008) Beitrag zur Zerspanung intermetallischer gamma-Titanaluminide durch Bohren, Gewindebohren und Fräsen. Dissertation, Dortmund University

Weinert K, Biermann D, Bergmann S (2007) Machining of high strength light weight alloys for engine applications. CIRP Ann 56(1):105–108

Roth M, Biermann H (2006) Thermo-mechanical fatigue behaviour of the γ-TiAl alloy TNB-V5. Scr Mater 54:137–141

Klocke F (2011) Manufacturing processes. 1—Cutting. RWTH edition. Springer, Berlin

Klocke F, Stegen A, Fritsch R (2008) Grundlagenuntersuchungen zur ultraschallunterstützen Zerspanung intermetallischer gamma-Titanaluminidlegierungen, DFG Abschlussbericht

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klocke, F., Lung, D., Arft, M. et al. On high-speed turning of a third-generation gamma titanium aluminide. Int J Adv Manuf Technol 65, 155–163 (2013). https://doi.org/10.1007/s00170-012-4157-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4157-5