Abstract

Variable blank holder force (VBHF) is an important process parameter in sheet metal forming. The purpose of this study is to propose a sharing niching radial basis function (SNRBF) neural network for VBHF optimization. Two methods are put forward to improve the prediction accuracy of a RBF neural network. (1) A RBF neural network is trained by a sharing niching technique to achieve global optimal nodes. (2) In Latin hypercube design, Spearman correlation analysis is employed to decrease sample correlation. In addition, in order to improve the performance of the non-dominated sorting genetic algorithm (NSGA-II), excellent individuals in each class of non-dominated individuals are selected by employing immune operators. Based on the Spearman correlation analysis and the Latin hypercube method, training samples are generated and numerical simulations are performed for a double C part. The surrogate models between VBHF and forming quality are constructed by a SNRBF neural network. The Pareto frontier solutions are achieved by employing the improved NSGA-II algorithm. Grey relational analysis is applied to determine the optimal VBHF loading trajectory. The results show decreased wrinkles in the optimized forming part and greater uniformity in the plastic deformation by employing the optimized VBHF, thereby leading to improvement in the forming quality of the double C.

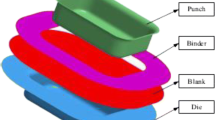

Graphical Abstract

Similar content being viewed by others

Abbreviations

- \(x_{i} ,x_{j} ,x_{k} ,x_{m} ,x_{n}\) :

-

The ith, jth, kth, mth, and nth individual

- \(d_{ij} ,d_{mn}\) :

-

Euclidean distance

- \(sh\left( {d_{ij} } \right),sh\left( {d_{mn} } \right)\) :

-

Shared function

- \(h_{i}\) \(H_{m}\) :

-

Shared degree

- \(f_{i}^{'}\) :

-

Shared fitness of the ith individual

- \(f_{i}\) :

-

Initial fitness of the ith individual

- \(\sigma_{share}\) :

-

Niche radius

- \(\omega_{st}\) :

-

Weight between the implicit layer and the input layer

- \(C_{s}\) :

-

The sth node data of hidden layer

- \(\rho_{m}\) :

-

Sum of Euclidean distances

- \(\rho_{i}^{\prime }\) :

-

Antibody density

- \(E_{i}\) :

-

Survival expectation of the antibody

- a:

-

A constant to adjust the shared function

- L, q:

-

The number of individuals

- \(D_{s}\) :

-

The width of hidden layer nodes

References

Lin, Z. Q., Wu, R., Wang, G. L., & Chen, A. (2007). New strategy to optimize variable blank holder force towards improving the forming limits of aluminum sheet metal forming. Journal of Materials Processing Technology, 183(2-3), 339–346.

Jakumeit, J., Herdy, M., & Nitsche, M. (2005). Parameter optimization of the sheet metal forming process using an iterative parallel kriging algorithm. Structural and Multidisciplinary Optimization, 29(6), 498–507.

Sun, C. Z., Chen, G. L., & Lin, Z. Q. (2005). Determining the optimum variable blank-holder forces using adaptive response surface methodology (ARSM). International Journal of Advanced Manufacturing Technology, 26(1–2), 23–29.

Wang, H., Chen, L., & Li, E. Y. (2018). Time dependent sheet metal forming optimization by using Gaussian process assisted firefly algorithm. International Journal of Material Forming, 11(2), 1–17.

Wang, H., Ye, F., & Chen, L. (2017). Sheet metal forming optimization by using surrogate modeling techniques. Chinese Journal of Mechanical Engineering, 30(1), 22–36.

Liew, K. M., Tan, H., & Ray, T. (2004). Optimal process design of sheet metal forming for minimum springback via an integrated neural network evolutionary algorithm. Structural and Multidisciplinary Optimization, 26(3–4), 284–294.

Cheng, P. J., & Lin, S. C. (2000). Using neural networks to predict bending angle of sheet metal formed by laser. International Journal of Machine Tools and Manufacture, 40(8), 1185–1197.

Fang, H., Rais-Rohani, M., & Liu, Z. (2005). A comparative study of metamodeling methods for multiobjective crashworthiness optimization. Computers and Structures, 83(25–26), 2121–2136.

Sun, G. Y., Li, G. Y., & Gong, Z. H. (2011). Radial basis functional model for multi-objective sheet metal forming optimization. Engineering Optimization, 43(12), 1351–1366.

Kitayama, S., Kita, K., & Yamazaki, K. (2012). Optimization of variable blank holder force trajectory by sequential approximate optimization with RBF network. International Journal of Advanced Manufacturing Technology, 61(9–12), 1067–1083.

Kitayama, S., Huang, S., & Yamazaki, K. (2013). Optimization of variable blank holder force trajectory for springback reduction via sequential approximate optimization with radial basis function network. Structural and Multidisciplinary Optimization, 47(2), 289–300.

Kitayama, S., Koyama, H., & Kawamoto, K. (2016). Numerical and experimental case study on simultaneous optimization of blank shape and variable blank holder force trajectory in deep drawing. Structural and Multidisciplinary Optimization, 55(1), 347–359.

Kitayama, S., Arakawa, M., & Yamazaki, K. (2011). Sequential approximate optimization using radial basis function network for engineering optimization. Optimization and Engineering, 12, 535–557.

Xie, Y. M., He, Y. J., & Tian, Y. (2016). Optimization of variable blank holder forces in sheet metal forming based on RBF neural network model. Journal of Southwest Jiaotong University in Chinese, 51(1), 121–127.

Wang, H., Li, G. Y., & Zhong, Z. H. (2008). Optimization of sheet metal forming processes by adaptive response surface based on intelligent sampling method. Journal of Materials Processing Technology, 197(1–3), 77–88.

Shabbir, F., & Omenzetter, P. (2015). Particle swarm optimization with sequential niche technique for dynamic finite element model updating. Computer‐Aided Civil and Infrastructure Engineering, 30(5), 359–375.

Liao, M., Liu, J., & Liu, Y. (2015). Optimal stamping direction for an automotive part. International Journal of Advanced Manufacturing Technology, 79(1–4), 285–297.

Tian, Y., Xie, Y. M., & Sun, X. Q. (2015). Optimization of variable blank holding force based on artificial immune algorithm and RBF neural network. Machine Tool and Hydraulics Chinese, 43(7), 6–9.

Man, C. T., Li, X., & Zhang, X. (2008). A new training algorithm for RBF neural network based on ACO. Journal of Harbin University Science Technology Chinese, 13(1), 56–63.

Deb, K., Pratap, A., & Agarwal, S. (2002). A fast and elitist multiobective genetic algorithm: NSGA-II. IEEE Transactions on Evolutionary Computation, 6(2), 182–197.

Tang, Y., & Chen, J. (2009). Robust design of sheet metal forming process based on adaptive importance sampling. Structural and Multidisciplinary Optimization, 39(5), 531–544.

Wang, J., Ma, Y. Z., & Wang, J. J. (2016). Applications of importance sampling based on Kriging meta model in structural reliability analysis. Computer Integrated Manufacturing Systems, 22(11), 2643–2652.

Goldberg, D., & Wang, L. (1997). Adaptive niching via coevolutionary sharing. Genetic Algorithms and Evolution Strategy in Engineering and Computer Science, 97007, 21–38.

Li, M. J., Luo, A., & Tong, T. S. (2004). Artificial immune algorithm and its applications. Control Theory and Applications, 21(2), 153–157.

Fang, K. T., Li, R., & Sudjianto, A. (2006). Design and modeling for computer experiments. Boca Raton: Chapman & Hall/CRC.

Xie, Y. M., Yu, H. P., & Chen, J. (2007). Application of grey relational analysis in sheet metal forming for multi-response quality characteristics. Journal of Zhejiang University Science A, 8(5), 805–811.

Xiao, Y. H., Liu, Y. L., & Yang, H. (2014). Optimization of processing parameters for double-ridged rectangular tube rotary draw bending based on grey relational analysis. International Journal of Advanced Manufacturing Technology, 70(9–12), 2003–2011.

Liu, Y. L., Jiang, Z. Y., & Liu, C. M. (2018). Optimization of processing parameters for a reverse drawing-flanging combined process for a B550CL high-strength steel spoke based on grey relational analysis. Metal, 8(7), 1–15.

Acknowledgements

The research was supported by the National Natural Science Foundation of China (NSFC51005193) and National Training Program of Innovation and Entrepreneurship for Undergraduates (201710613033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xie, Y., Tang, W., Zhang, F. et al. Optimization of Variable Blank Holder Force Based on a Sharing Niching RBF Neural Network and an Improved NSGA-II Algorithm. Int. J. Precis. Eng. Manuf. 20, 285–299 (2019). https://doi.org/10.1007/s12541-019-00019-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00019-x