Abstract

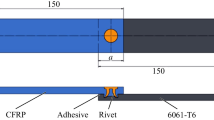

Recently, the tightening method on the machine structure has been used by only adhesive rather than existing bolts and nuts because of light weight problem. As for the porous material such as aluminum foam, the tightening is also possible by using adhesive in the aspect of material's characteristics. In case of the structure tightened by using only adhesive, it is necessary that the fracture toughness data as a part of adhesive joint are requested in order to use safely. Because the adhesive failure characteristic of the aluminum foam which is the porous material is different from the non-porous material, the study on the fracture toughness of the adhesive interface of aluminum is important. In this study, the static experiment was performed on the adhesive specimen with the aluminum foam of DCB on tearing mode. The thicknesses of specimens were 35 mm, 45 mm, and 55 mm, respectively. In case of 35 mm thickness specimen, the maximum reaction of about 0.57 kN occurred when the forced displacement was progressed by about 7 mm. When the forced displacement was progressed by about 8 mm, the maximum reaction of about 0.68 kN occurred in case of 55 mm thickness specimen. And the simulation analysis was carried by using the finite-element analysis program of ANSYS in order to verify the experimental results. This study showed the similar trend at the results between experiment and simulation. Through the results of this study, it can be thought that the simulation analysis data may be applied to the actual jointed part of porous material.

Similar content being viewed by others

References

Bai, Y. L., Johnson, W., and Dodd, B., “On Tangential Velocity Discontinuities being Coincident with Stress Discontinuities,” International Journal of Mechanical Sciences, Vol. 24, No. 5, pp. 323–328, 1982.

Kim, S.-S., Han, M.-S., Cho, J.-U., and Cho, C.-D., “Study on the Fatigue Experiment of TDCB Aluminum Foam Specimen Bonded with Adhesive,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 10, pp. 1791–1795, 2013.

Parida, S. K. and Pradhan, A. K., “3D Finite Element Analysis of Stress Distributions and Strain Energy Release Rates for Adhesive Bonded Flat Composite Lap Shear Joints Having Pre-Existing Delaminations,” Journal of Mechanical Science and Technology, Vol. 28, No. 2, pp. 481–488, 2014.

Batra, R. and Peng, Z., “Development of Shear Bands in Dynamic Plane Strain Compression of Depleted Uranium and Tungsten Blocks,” International Journal of Impact Engineering, Vol. 16, No. 3, pp. 375–395, 1995.

Mukai, T., Miyoshi, T., Nakano, S., Somekawa, H., and Higashi, K., “Compressive Response of a Closed-Cell Aluminum Foam at High Strain Rate,” Scripta Materialia, Vol. 54, No. 4, pp. 533–537, 2006.

Cho, J. U., Hong, S. J., Lee, S. K., and Cho, C., “Impact Fracture Behavior at the Material of Aluminum Foam,” Materials Science and Engineering: A, Vol. 539, pp. 250–258, 2012.

Pirondi, A. and Nicoletto, G., “Fatigue Crack Growth in Bonded DCB Specimens,” Engineering Fracture Mechanics, Vol. 71, No. 4, pp. 859–871, 2004.

Shokrieh, M. M., Heidari-Rarani, M., and Rahimi, S., “Influence of Curved Delamination Front on Toughness of Multidirectional DCB Specimens,” Composite Structures, Vol. 94, No. 4, pp. 1359–1365, 2012.

Blackman, B. P. K., Dear, J. P., Kinloch, A. J., Macgillivray, H., Wang, Y., et al., “The Failure of Fibre Composites and Adhesively Bonded Fibre Composites under High Rates of Test,” Journal of Materials Science, Vol. 30, No. 23, pp. 5885–5900, 1995.

Marzi, S., Biel, A., and Stigh, U., “On Experimental Methods to Investigate the Effect of Layer Thickness on the Fracture Behavior of Adhesively Bonded Joints,” International Journal of Adhesion and Adhesives, Vol. 31, No. 8, pp. 840–850, 2011.

Cho, J.-U., Kinloch, A., Blackman, B., Rodriguez, S., Cho, C.-D., and Lee, S.-K., “Fracture Behaviour of Adhesively-Bonded Composite Materials under Impact Loading,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 1, pp. 89–95, 2010.

Cooper, V., Ivankovic, A., Karac, A., McAuliffe, D., and Murphy, N., “Effects of Bond Gap Thickness on the Fracture of Nano-Toughened Epoxy Adhesive Joints,” Polymer, Vol. 53, No. 24, pp. 5540–5553, 2012.

Ghaffarzadeh, H. and Nikkar, A., “Explicit Solution to the Large Deformation of a Cantilever Beam under Point Load at the Free Tip using the Variational Iteration Method-II,” Journal of Mechanical Science and Technology, Vol. 27, No. 11, pp. 3433–3438, 2013.

Goncalves, J. P. M., De Moura, M. F. S. F., and De Castro, P. M. S. T., “A Three-Dimensional Finite Element Model for Stress Analysis of Adhesive Joints,” International Journal of Adhesion and Adhesives, Vol. 22, No. 5, pp. 357–365, 2002.

Kim, K. S., Yoo, J. S., Yi, Y. M., and Kin, C. G. R., “The Strength and Failure Modes and of Singlelap Adhesively Bonded Composite Joints Formed using Different Bonding Methods- Co-Curing with/without Adhesive and Secondary Bonding,” Composite Structures, Vol. 25, No. pp. 45, 2005.

Crocombe, A. D. and Richardson, G., “Assessing Stress State and Mean Load Effects on the Fatigue Response of Adhesively Bonded Joints,” International Journal of Adhesion and Adhesives, Vol. 19, No. 1, pp. 19–27, 1999.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J.H., Cho, J.U. Fracture behavior on the structures of DCB jointed with aluminum foam in tearing mode. Int. J. Precis. Eng. Manuf. 17, 897–902 (2016). https://doi.org/10.1007/s12541-016-0109-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0109-6