Abstract

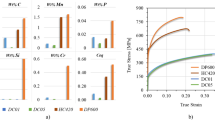

This study consists of a numerical investigation of high-speed blanking of mild steel. A finite element model of the high-speed blanking process was developed using ABAQUS/explicit, and the strain rate and temperature-dependent behavior of the work material were included in the model by using the Johnson-Cook hardening model for mild steel. The blanking simulations had a punch speed ranging from 30 mm/s to 60 mm/s to study the influence of the thermal behavior of mild steel on the blanking force. In addition, the influence that the clearance, thickness of the work material and tool edge radius had on the blanking force was studied while changing the punch speed. The simulations revealed that the blanking force decreases when the punch speed increases beyond a certain amount as a result of thermal softening of the mild steel. Also, the clearance, material thickness and tool edge radius were observed to influence the development of the temperature. The results of this study can help understand the high-speed blanking process in order to design an apparatus for further research into high-speed blanking.

Similar content being viewed by others

Abbreviations

- \(\bar \sigma \) :

-

Equivalent stress

- A, B, n, C, m :

-

Parameters for the Johnson-Cook model

- \(\dot \varepsilon *\) :

-

Normalized strain rate

- \(\dot \varepsilon \) :

-

Equivalent strain rate

- \({\dot \varepsilon _0}\) :

-

Reference strain rate

- C p :

-

Specific heat

- K :

-

Thermal conductivity

References

Balakrishnan, M. and Issac, J. C., “Design of the Multi-Stage Progressive Tool for Blanking a Sheet Metal Component,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 5, pp. 875–881, 2014.

Jana, S. and Ong, N., “Effect of Punch Clearance in the High-Speed Blanking of Thick Metals using an Accelerator Designed for a Mechanical Press,” Journal of Mechanical Working Technology, Vol. 19, No. 1, pp. 55–72, 1989.

Gaudilliere, C., Ranc, N., Larue, A., and Lorong, P., “Investigations in High Speed Blanking: Cutting Forces and Microscopic Observations,” Proc. of 14th International Conference on Experimental Mechanics, Vol. 6, Article No. 19003, 2010.

Stegeman, Y. W., Goijaerts, A. M., Brokken, D., Brekelmans, W. A. M., Govaert, L. E., and Baaijens, F. P. T., “An Experimental and Numerical Study of a Planar Blanking Process,” Journal of Materials Processing Technology, Vol. 87, No. 1, pp. 266–276, 1999.

Marouani, H., Ismail, A. B., Hug, E., and Rachik, M., “Numerical Investigations on Sheet Metal Blanking with High Speed Deformation,” Materials & Design, Vol. 30, No. 9, pp. 3566–3571, 2009.

Hu, D.-C., Chen, M.-H., Ouyang, J.-D., and Yin, L.-M., “Finite Element Analysis of the Thermal Effect in High-Speed Blanking of Thick Sheet Metal,” The International Journal of Advanced Manufacturing Technology, Vol. 80, No. 9–12, pp. 1481–1487, 2015.

Gaudilliere, C., Ranc, N., Larue, A., Maillard, A., and Lorong, P., “High Speed Blanking: An Experimental Method to Measure Induced Cutting Forces,” Experimental Mechanics, Vol. 53, No. 7, pp. 1117–1126, 2013.

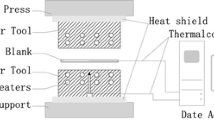

Slavi, J., Bolka,., Bratu, V., and Boltear, M., “A Novel Laboratory Blanking Apparatus for the Experimental Identification of Blanking Parameters,” Journal of Materials Processing Technology, Vol. 214, No. 2, pp. 507–513, 2014.

Johnson, G. R. and Cook, W. H., “A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures,” Proc. of the 7th International Symposium on Ballistics, pp. 541–547, 1983.

Iqbal, M. A., Senthil, K., Bhargava, P., and Gupta, N. K., “The Characterization and Ballistic Evaluation of Mild Steel,” International Journal of Impact Engineering, Vol. 78, pp. 98–113, 2015.

Seli, H., Awang, M., Ismail, A. I. M., Rachman, E., and Ahmad, Z. A., “Evaluation of Properties and FEM Model of the Friction Welded Mild Steel-Al6061-Alumina,” Materials Research, Vol. 16, No. 2, pp. 453–467, 2013.

Jeong, H., Ha, J., Hwang, J., Lee, H., Kim, D., and Kim, N., “A Study on the Shearing Process and the Burr Formation of Zircaloy-4 Sheet by using GTN Model,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 10, pp. 2167–2175, 2014.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, SH., Choi, W.C. FEM investigation on thermal effects on force in high-speed blanking of mild steel. Int. J. Precis. Eng. Manuf. 17, 631–635 (2016). https://doi.org/10.1007/s12541-016-0076-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0076-y