Abstract

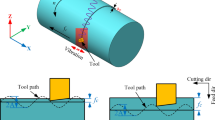

A micro hole is a basic feature in micro manufacturing. Micro electrical discharge machining (EDM) is one of the key techniques for machining micro holes in metallic materials. Since debris is accumulated in the discharging gap between the tool electrode and the workpiece, it becomes increasingly very difficult to machine a micro hole as the chosen diameter is progressively decreased or the depth increased. The use of vibration in micro EDM drilling can improve machining efficiency by refreshing dielectric fluids and flushing out the debris from the gap. Although ultrasonic vibration over a few kHz has been introduced in many applications of micro EDM, it is difficult to apply to a workpiece of a very large size or mass. In this study, the effect of very-low-frequency vibration was investigated to improve the efficiency of micro EDM. Low-frequency vibration in the range of 10 to 70 Hz was applied to single-hole machining, to reverse EDM, and to multiple-hole machining. The machining efficiency was investigated while varying the vibration frequency and amplitude.

Similar content being viewed by others

References

Shin, H. S., Park, M. S., Kim, B. H., and Chu, C. N., “Recent Researches in Micro Electrical Machining,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 371–380, 2011.

Ferraris, E., Castiglioni, V., Ceyssens, F., Annoni, M., Lauwers, B., and Reynaerts, D., “EDM Drilling of Ultra-High Aspect Ratio Micro Holes with Insulated Tools,” CIRP Annals-Manufacturing Technology, Vol. 62, No. 1, pp. 191–194, 2013.

Nguyen, K.-H., Lee, P. A., and Kim, B. H., “Experimental Investigation of ECDM for Fabricating Micro Structures of Quartz,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 1, pp. 5–12, 2015.

Yu, Z., Ma, C., An, C., Li, J., and Guo, D., “Prediction of Tool Wear in Micro USM,” CIRP Annals-Manufacturing Technology, Vol. 61, No. 1, pp. 227–230, 2012.

Romoli, L., Rashed, C. A. A., Lovicu, G., Dini, G., Tantussi, F., et al., “Ultrashort Pulsed Laser Drilling and Surface Structuring of Microholes in Stainless Steels,” CIRP Annals-Manufacturing Technology, Vol. 63, No. 1, pp. 229–232, 2014.

Sambhav, K., Tandon, P., Kapoor, S. G., and Dhande, S. G., “Mathematical Modeling of Cutting Forces in Microdrilling,” Journal of Manufacturing Science and Engineering, Vol. 135, No. 1, Paper No. 014501, 2013.

Zabel, A. and Heilmann, M., “Deep Hole Drilling using Tools with Small Diameters-Process Analysis and Process Design,” CIRP Annals-Manufacturing Technology, Vol. 61, No. 1, pp. 111–114, 2012.

Kim, B. H., Ryu, S. H., Choi, D. K., and Chu, C. N., “Micro Electrochemical Milling,” Journal of Micromechanics and Microengineering, Vol. 15, No. 1, pp. 124–129, 2005.

Kunieda, M. and Masuzawa, T., “A Fundamental Study on a Horizontal EDM,” CIRP Annals-Manufacturing Technology, Vol. 37, No. 1, pp. 187–190, 1988.

Kim, B. H., “Micro Hole Machining using MEDM with Screw-Type Electrode,” M.Sc. Thesis, Department of Mechanical Design and Production Engineering, Seoul National University, 1999.

Masuzawa, T., Tsukamoto, J., and Fujino, M., “Drilling of Deep Microholes by EDM,” CIRP Annals-Manufacturing Technology, Vol. 38, No. 1, pp. 195–198, 1989.

Plaza, S., Sanchez, J. A., Perez, E., Gil, R., Izquierdo, B., et al., “Experimental Study on Micro Edm-Drilling of Ti6Al4V using Helical Electrode,” Precision Engineering, Vol. 38, No. 4, pp. 821–827, 2014.

Yu, Z. Y., Rajurkar, K. P., and Shen, H., “High Aspect Ratio and Complex Shaped Blind Micro Holes by Micro EDM,” CiRP Annals-Manufacturing Technology, Vol. 51, No. 1, pp. 359–362, 2002.

Yu, Z. Y., Zhang, Y., Li, J., Luan, J., Zhao, F., and Guo, D., “High Aspect Ratio Micro-Hole Drilling Aided with Ultrasonic Vibration and Planetary Movement of Electrode by Micro-EDM,” CIRP Annals-Manufacturing Technology, Vol. 58, No. 1, pp. 213–216, 2009.

Bamberg, E. and Heamawatanachai, S., “Orbital Electrode Actuation to Improve Efficiency of Drilling Micro-Holes by Micro-EDM,” Journal of Materials Processing Technology, Vol. 209, No. 4, pp. 1826–1834, 2009.

Huang, H., Zhang, H., Zhou, L., and Zheng, H., “Ultrasonic Vibration Assisted Electro-Discharge Machining of Microholes in Nitinol,” Journal of Micromechanics and Microengineering, Vol. 13, No. 5, pp. 69–700, 2003.

Kremer, D., Lebrun, J. L., Hosari, B., and Moisan, A., “Effects of Ultrasonic Vibrations on the Performances in EDM,” CIRP Annals-Manufacturing Technology, Vol. 38, No. 1, pp. 199–202, 1989.

Gao, C. and Liu, Z., “A Study of Ultrasonically Aided Micro-Electrical-Discharge Machining by the Application of Workpiece Vibration,” Journal of Materials Processing Technology, Vol. 139, No. 1–3, pp. 226–228, 2003.

Garn, R., Schubert, A., and Zeidler, H., “Analysis of the Effect of Vibrations on the Micro-EDM Process at the Workpiece Surface,” Precision Engineering, Vol. 35, No. 2, pp. 364–368, 2011.

Kim, D. J., Yi, S. M., Lee, Y. S., and Chu, C. N., “Straight Hole Micro EDM with a Cylindrical Tool using a Variable Capacitance Method Accompanied by Ultrasonic Vibration,” Journal of Micromechanics and Microengineering, Vol. 16, No. 5, pp. 1092–1097, 2006.

Tong, H., Li, Y., and Wang, Y., “Experimental Research on Vibration Assisted EDM of Micro-Structures with Non-Circular Cross-Section,” Journal of Materials Processing Technology, Vol. 208, No. 1, pp. 289–298, 2008.

Yu, Z., Rajurkar, K. P., and Narasimhan, J., “Effect of Machining Parameters on Machining Performance of Micro EDM and Surface Integrity,” Proc. of 18th Annual ASPE Meeting, 2003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, P.A., Kim, Y. & Kim, B.H. Effect of low frequency vibration on micro EDM drilling. Int. J. Precis. Eng. Manuf. 16, 2617–2622 (2015). https://doi.org/10.1007/s12541-015-0335-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0335-3