Abstract

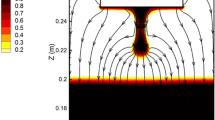

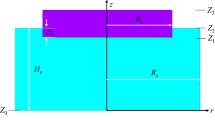

A transient three-dimensional (3D) model has been developed to investigate the impact of the solidified slag on the heat transfer and magnetohydrodynamic (MHD) flow during the electroslag remelting process. The solution of the mass, momentum, and energy conservation equations are simultaneously implemented by the finite volume method with full coupling of the Joule heating and Lorentz force through solving the Maxwell’s equations. The solidification is modeled by an enthalpy-based technique. A reasonable agreement is obtained between the experiment and simulation. The results definitely highlight that the solidified slag skin does not behave as a perfect electrical insulator during the process. The electrical insulation hypothesis of the solidified slag makes a significant influence on physical fields which must be used with extreme care.

Similar content being viewed by others

References

Hernandez-Morales, B. and Mitchell, A., “Review of Mathematical Models of Fluid Flow, Heat Transfer, and Mass Transfer in Electroslag Remelting Process,” Ironmaking & Steelmaking, Vol. 26, No. 6, pp. 423–438, 1999.

Jardy, A., Ablitzer, D., and Wadier, J. F., “Magnetohydronamic and Thermal Behavior of Electroslag Remelting Slags,” MTB, Vol. 22, No. 1, pp. 111–120, 1991.

Ludwig, A., Kharicha, A., and Wu, M., “Modeling of Multiscale and Multiphase Phenomena in Materials Processing,” Metallurgical and Materials Transactions B, Vol. 45, No. 1, pp. 36–43, 2014.

Fezi, K., Yanke, J., and Krane, M. J., “Modeling Macrosegregation during Electroslag Remelting of Alloy 625,” Proc. of the 2013 International Symposium on Liquid Metal Processing and Casting (LMPC), pp. 151–158, 2013.

Weber, V., Jardy, A., Dussoubs, B., Ablitzer, D., Rybé ron, S., et al., “A Comprehensive Model of the Electroslag Remelting Process: Description and Validation,” Metallurgical and Materials Transactions B, Vol. 40, No. 3, pp. 271–280, 2009.

Ferng, Y. M., Chieng, C. C., and Pan, C., “Numerical Simulations of Electro-Slag Remelting Process,” Numerical Heat Transfer, Vol. 16, No. 4, pp. 429–449, 1989.

Mitchell, A., “Solidification in Remelting Processes,” Materials Science and Engineering: A, Vols. 413-414, pp. 10–18, 2005.

Kharicha, A., Ludwig, A., and Wu, M., “Shape and Stability of the Slag/Melt Interface in a Small DCESR Process,” Materials Science and Engineering: A, Vol. 413-414, pp. 129–134, 2005.

Hugo, M., Dussoubs, B., Jardy, A., Escaffre, J., and Poisson, H., “Impact of the Solidified Slag Skin on the Current Distribution during Electroslag Remelting,” Proc. of the 2013 International Symposium on Liquid Metal Processing and Casting, pp. 79–85, 2013.

Patel, A. D., “Effect of Electrode Pipe and Mold Current on Electromagnetic Fields in ESR,” Proc. of International Symposium on Liquid Metal Processing and Casting LMPC, pp. 95–100, 2007.

Kharicha, A., Schutzenhofer, W., Ludwig, A., Tamer, R., and Wu, M., “On the Importance of Electric Currents Flowing Directly into the Mould during an Esr Process,” Steel Research International, Vol. 79, No. 8, pp. 632–636, 2008.

Li, B., Wang, F., and Tsukihashi, F., “Current, Magnetic Field and Joule Heating in Electroslag Remelting Processes,” ISIJ International, Vol. 52, No. 7, pp. 1289–1295, 2012.

Li, B., Wang, B., and Tsukihashi, F., “Modeling of Electromagnetic Field and Liquid Metal Pool Shape in an Electroslag Remelting Process with Two Series-Connected Electrodes,” Metallurgical and Materials Transactions B, Vol. 45, No. 3, pp. 1122–1132, 2014.

Biro, O. and Preis, K., “On the Use of the Magnetic Vector Potential in the Finite-Element Analysis of Three-Dimensional Eddy Currents,” IEEE Transactions on Magnetics, Vol. 25, No. 4, pp. 3145–3159, 1989.

Wang, Q., He, Z., Li, B., and Tsukihashi, F., “A General Coupled Mathematical Model of Electromagnetic Phenomena, Two-Phase Flow, and Heat Transfer in Electroslag Remelting Process including Conducting in the Mold,” Metallurgical and Materials Transactions B, Vol. 45, No. 6, pp. 2425–2441, 2014.

Wang, Q., Zhao, R., Fafard, M., and Li, B., “Three-Dimensional Magnetohydrodynamic Two-Phase Flow and Heat Transfer Analysis in Electroslag Remelting Process,” Applied Thermal Engineering, Vol. 80, pp. 178–186, 2015.

Kelkar, K. M., Patankar, S. V., and Mitchell, A., “Computational Modeling of the Electroslag Remelting (ESR) Process used for the Production of Ingots of High-Performance Alloys,” Proc. of 2005 International Symposium on Liquid Metal Processing and Casting, pp. 137–144, 2005.

Yanke, J. and Krane, M. J. M., “A Parametric Study of Slag Skin Formation in Electroslag Remelting,” Proc. of the 2013 International Symposium on Liquid Metal Processing and Casting, pp. 71–78, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Li, B. Effect of solidified slag on magnetohydrodynamic flow and heat transfer in electroslag remelting process. Int. J. Precis. Eng. Manuf. 16, 2193–2198 (2015). https://doi.org/10.1007/s12541-015-0282-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0282-z