Abstract

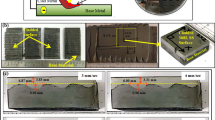

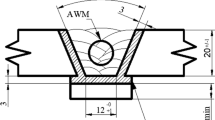

We have investigated the traits of clad metals in hot-rolled clad steel plates, including the sensitization and mechanical properties of STS 316 steel plate and carbon steel (A516), under various specific circumstances regarding post heat treatment, multilayered welds, and thick or repeated welds for repair. For evaluations, sectioned weldments and external surfaces were investigated to reveal the degree of sensitization by Micro Vickers hardness, tensile, and etching tests, and the results were compared with those of EPR tests. Clad steel plates were butt-welded using SAW + SMAW, and with the time of heat treatment as the variable, heat treatment was conducted at 625°C, for 80, 160, 320, 640, and 1280 minutes. Then, the change in corrosion resistance was evaluated in these specimens. With carbon steel (A516), as the heat treatment time increased, the annealing effect caused the tensile strength to decrease. The micro-hardness gradually increased and decreased after 640 min. The elongation and contraction of the area also increased gradually. The oxalic acid etch test and EPR test on STS316, a clad metal, showed STEP structure and no sensitization. From the test results on multi-layered and repair welds, it could be concluded that there is no effect on the corrosion resistance of clad metals. The purpose of this study was to suggest some considerations for developing on-site techniques to evaluate the sensitization of stainless steels.

Similar content being viewed by others

References

Lee, C. K. and Park, J. W., “Comparison of mechanical properties and sensitization of clad steel weld zone with FCAW,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 12, pp. 2209–2214, 2012.

Bell, F. C. and Sonon, D. E., “Improved metallographic etching techniques for stainless steel and for stainless steel to carbon steel weldments,” Metallography, Vol. 9, No. 2, pp. 91–107, 1976.

Liljas, M., “Proceedings of the fourths international conference on duplex stainless steels,” Keynote Paper V, Vol. 2, No. pp. 13–16, 1994.

Yoo, Y., Shin, H., and Jang, W., “Surface heat treatment of die material by means of CW Nd: YAG laser,” Transaction of KSMTE, Vol. 13, No. 5, pp. 67–74, 2004.

ASTMA262-93a, “Standard practices for detecting susceptibility to intergranular attack in austenitic stainless steels,” 1993.

ASTM G108-94, “Standard test method for electrochemical reactivation (EPR) for detecting sensitization of AISI type 304 and 304L stainless steels,” 1994.

Na, G., Yoo, Y., Shin, B., and Shin, H., “A study on the surface hardening of SCM4 steel using a continuous wave Nd: YAG laser,” Transaction of KSMTE, Vol. 16, No. 5, pp. 24–32, 2007.

Park, C. E., Liand, C. S., and Kim, l. S., “Mathematical models for optimal bead geometry for GMA welding process,” International Journal of Korean Welding Society, Vol. 3, No. 1, pp. 8–16, 2003.

Russell, J. H., Covino Jr, B. S., and Bullard, S. J., “Applications of electrochemical methods for investigations of localized corrosion of nitrogen-molybdenum stainless steels,” Corrosion, Vol. 57, No. 4, pp. 360–368, 2001.

Saito, N., Tsuchiya, Y., Kano, F., and Tanaka, N., “Variation of slow strain rate test fracture mode of type 304L stainless steel in 288°C water,” Corrosion, Vol. 56, No. 1, pp. 57–69, 2000.

Kim, W. G., Yin, S. N., Ryu, W. S., and Won, Y., “Creep properties of type 316LN steel welded by the SAW method,” pp. 105–106, Proc. of KSPE Spring Conference, 2006.

ASTM A240/A240M-13a, “Standard specification for chromium and chromium-nickel stainless steel plate, Sheet, and Strip for Pressure Vessels and for general applications,”, 2003.

Matsuda, F. et al., “Effect of electromagnetic stirring on weld solidification structure of aluminum alloys,” Proc. of the International conference on arc physics and weld Pool Behavior, pp. 337–347, 1980.

Clarke, W. L., “The EPR technique for the detection of sensitization in stainless steel, General electric report, GEAP-24888, April,” National technical information service as NUREG/CR-1095, Springfield, Virginia 22161, 1981.

Cihal, V., Stefec, R., Shoji, T., Watanabe, Y., and Kain, V., “Electrochemical potentiodynamic reactivation: Development and applications of the EPR test,” Key Engineering Materials, Vol. 261–263, pp. 855–864, 2004.

Clarke, W. and Carlson, D., “Nondestructive measurement of sensitization of stainless steel: Relation to high temperature stress corrosion behavior,” Corrosion’79, pp. 16–23, 1979.

Aydodu, G. H. and Aydinol, M. K., “Determination of susceptibility to intergranular corrosion and electrochemical reactivation behavior of AISI 316L type stainless steel,” Corrosion Science, Vol. 48, No. 11, pp. 3565–3583, 2006.

Majidi, A. P. and Streicher, M. A., “The double loop reactivation method for detecting sensitization in AISI 304 stainless steels,” Corrosion, Vol. 40, No. 11, pp. 584–593, 1984.

Lee, C. K. and Park, J. W., “The sensitization and intergranular corrosion behavior of AISI 316L clad steel with butt welding,” Journal of the Korean Welding and Joining Society, Vol. 31, No. 2, pp. 49–56, 2013.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, JW., Lee, CK. Mechanical properties and sensitization on clad steel welding design. Int. J. Precis. Eng. Manuf. 14, 1939–1945 (2013). https://doi.org/10.1007/s12541-013-0263-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0263-z