Abstract

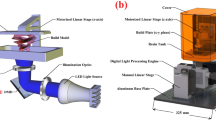

Microstereolithography (μSL) is similar to the conventional stereolithography process and allows the fabrication of complex microstructures with high aspect ratios. In the projection μSL process, each layer is fabricated by one irradiation of the light which has a cross-sectional shape. At this time, the fabrication range is limited by the field of view of pattern generator (LCD or DMD) and the magnification of the objective lens. In this study, we propose a partitioned cross-section method for expanding the fabrication range while maintaining the fabrication resolution in the projection μSL system. A cross-section is partitioned into several sub-sections, having required size in the pattern generator. Then, the shaped light corresponding to sub-section is irradiated at specific position on the resin surface, and cured sub-sections make completed cross-section. The procedure for generating a series of sub-sections has been presented. Using this method, some microstructures have been fabricated.

Similar content being viewed by others

References

Varadan, V. K., Jiang, X. and Varadan, V. V., “Microstereolithography and other fabrication techniques for 3D MEMS,” John Wiley & Sons, pp. 103–138, 2001.

Ikuta, K. and Kirowatari, K., “Real three dimensional micro fabrication using stereo lithography and metal molding,” Proceedings of the 6th IEEE Workshop on Micro Electro Mechanical Systems (MEMS’93), pp. 42–47, 1993.

Ikuta, K., Ogota, T., Tsubio, M. and Kojima, S., “Development of mass productive micro stereolithography,” Proceedings of the 8th IEEE Workshop on Micro Electro Mechanical Systems (MEMS’96), pp. 301–306, 1996.

Zhang, X., Jiang, X. N. and Sun, C., “Microstereolithography of polymeric and ceramic microstructures,” Sensors and Actuators A, Vol. 77,Issue 2, pp. 149–156, 1999.

Lee, I. H. and Cho, D. W., “An investigation on photopolymer solidification considering laser irradiation energy in microstereolithography,” Microsystem Technologies, Vol. 10, No. 8, pp. 592–598, 2004.

Bertsch, A., Zissi, S., Jezequel, J. Y., Corbel, S. and Andre, J. C., “Microstereophotolithography using a liquid crystal display as dynamic mask-generator,” Microsystem Technologies, Vol. 3, No. 2, pp. 42–47, 1997.

Farsari, M., Tournier, F. C., Huang, S., Chatwin, C. R., Budgett, D. M., Birch, P. M., Young, R. C. D. and Richardson, J. D., “A novel high-accuracy microstereolithography method employing an adaptive electro-optic mask,” Journal of Materials Processing Technology, Vol. 107, No. 1, pp. 167–172, 2000.

Provin, C. and Monneret, S., “Complex ceramic-polymer composite microparts made by microstereolithography,” IEEE Transactions on Electronics Packaging Manufacturing, Vol. 25, No. 1, pp. 59–63, 2002.

Oda, G., Miyoshi, T., Takaya, Y., Ha, T. H. and Kimura, K., “Microfabrication of overhanging shape using LCD microstereolithography,” Proceedings of SPIE, Vol. 5662, pp. 649–654, 2004.

Bertsch, A., Bernhard, P., Vogt, C. and Renaud, P., “Rapid prototyping of small size objects,” Rapid Prototyping Journal, Vol. 6, No. 4, pp. 259–266, 2000.

Bertsch, A., Jiguet, S. and Renaud, P., “Microfabrication of ceramic components by microstereolithography,” Journal of Micromechanics and Microengineering, Vol. 14, No. 2, pp. 197–203, 2004.

Sun, C., Fang, N., Wu, D. M. and Zhang, X., “Projection microstereolithography using digital micro-mirror dynamic mask,” Sensors and Actuators A, Vol. 121,Issue 1, pp. 113–120, 2005.

Choi, J. W., Ha, Y. M., Lee, S. H. and Choi, K. H., “Design of microstereolithography system based on dynamic image projection for fabrication of three-dimensional microstructures,” Journal of Mechanical Science and Technology, Vol. 20, No. 12, pp. 2094–2104, 2006.

Choi, J. W., Ha, Y. M. and Lee, S. H., “Fabrication of microstructure array using the projection microstereolithography system,” Journal of Korean Society for Precision Engineering, Vol. 24, No. 8, pp. 138–143, 2007.

Ha, Y. M., Choi, J. W., Lee, S. H. and Kim, H. C., “Fabrication of 3D Micro-structure on Large Surface using Projection Type Microstereolithography,” Asian Symposium for Precision Engineering and Nanotechnology (ASPEN 2007), pp. 492–495, 2007.

Ha, Y. M., Choi, J. W. and Lee, S. H., “Mass production of 3D microstructures using projection microstereolithography,” Journal of Mechanical Science and Technology, Vol. 22, No. 3, pp. 514–521, 2008.

Park, I. B., Choi, J. W., Ha, Y. M. and Lee, S. H., “Multiple fabrication of sacrificial layers to enhance the dimensional accuracy of microstructures in maskless projection microstereolithography,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 1, pp. 91–98, 2009.

Park, C. H., Song, C. K., Hwang, J. H. and Kim, B. S., “Development of an ultra precision machine tool for micromachining on large surfaces,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 4, pp. 85–91, 2009.

Noh, Y. J., Arai, Y., Tano, M. and Gao, W., “Fabrication of Large-area Micro-lens Arrays with Fast Tool Control,” Int. J. Precis. Eng. Manuf., Vol. 9, No. 4, pp. 32–38, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ha, YM., Park, IB., Kim, HC. et al. Three-dimensional microstructure using partitioned cross-sections in projection microstereolithography. Int. J. Precis. Eng. Manuf. 11, 335–340 (2010). https://doi.org/10.1007/s12541-010-0039-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-010-0039-7